Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Strip Presser position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

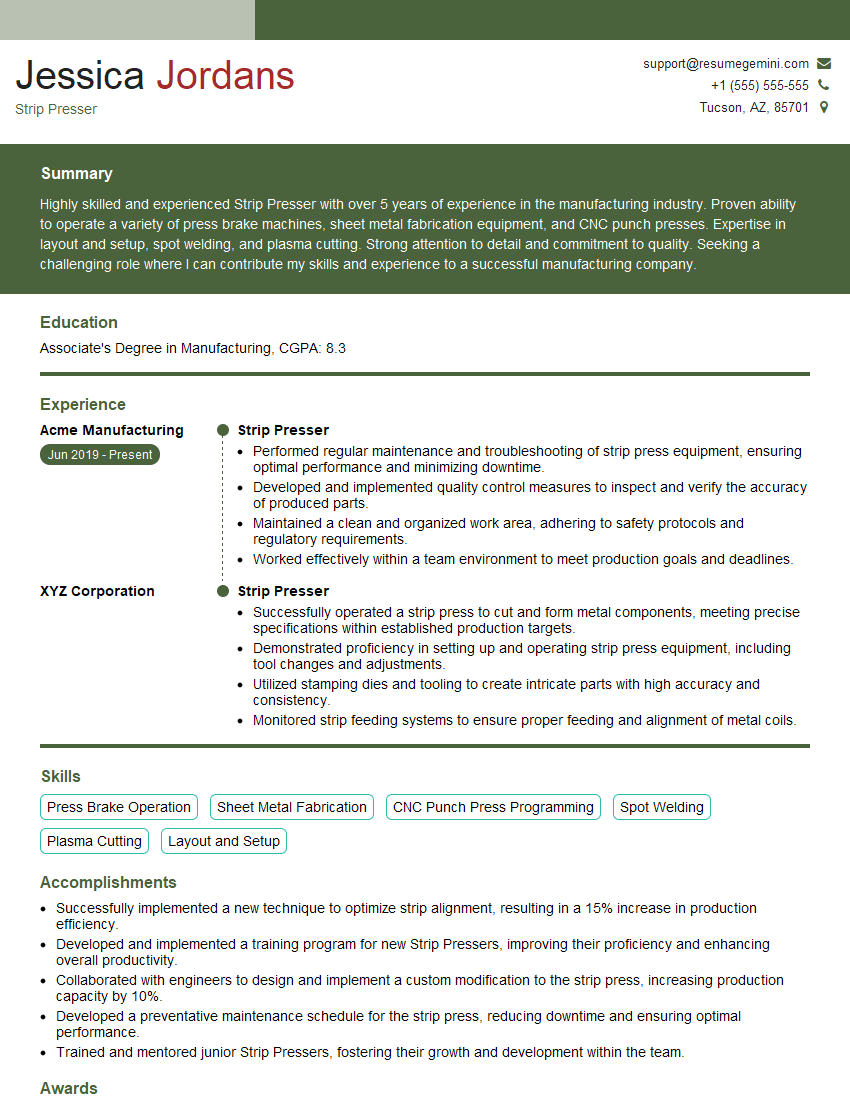

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Strip Presser

1. What are the key responsibilities of a Strip Presser?

- Strips metal, plastic, or other materials from coils or sheets using a strip press.

- Sets up and operates the strip press, making sure that it is properly adjusted and calibrated.

- Inspects the stripped materials for defects and makes adjustments to the machine as needed.

- Maintains the strip press and keeps it clean and in good working condition.

- May also be responsible for other tasks such as loading and unloading materials, operating other machines, or assisting other operators.

2. What types of strip presses are you familiar with?

Manual Strip Presses

- Requires the operator to manually feed the material into the press.

- Can be used for a variety of materials, including metal, plastic, and rubber.

- Less expensive than automated strip presses.

Automated Strip Presses

- Uses a conveyor belt to feed the material into the press.

- Can be more efficient than manual strip presses.

- Can be used for a variety of materials, including metal, plastic, and rubber.

- More expensive than manual strip presses.

3. What are the safety precautions that should be taken when operating a strip press?

- Wear appropriate safety gear, including gloves, safety glasses, and hearing protection.

- Keep hands and fingers away from the moving parts of the press.

- Never attempt to clear a jam while the press is running.

- Be aware of the location of the emergency stop button and know how to use it.

- Follow all manufacturer’s instructions for safe operation.

4. What are the different types of materials that can be stripped using a strip press?

- Metal (e.g., steel, aluminum, copper)

- Plastic (e.g., polyethylene, polypropylene, PVC)

- Rubber

- Paper

- Cloth

5. What are the factors that affect the quality of the stripped materials?

- The type of material being stripped

- The condition of the strip press

- The skill of the operator

- The settings of the strip press

- The environment (e.g., temperature, humidity)

6. What are the common problems that can occur when operating a strip press?

- Stripped materials are not the correct size or shape.

- Stripped materials are damaged or defective.

- The strip press is malfunctioning.

- The operator is injured.

7. How do you troubleshoot a strip press that is not functioning properly?

- Check the power supply to the press.

- Check the hydraulic system for leaks or blockages.

- Check the electrical system for loose connections or faulty components.

- Check the mechanical components for wear or damage.

- Refer to the manufacturer’s troubleshooting guide for more specific instructions.

8. What is the maintenance schedule for a strip press?

- Daily: Check the power supply, hydraulic system, electrical system, and mechanical components for any signs of damage or wear.

- Weekly: Lubricate the moving parts of the press.

- Monthly: Inspect the press for any signs of damage or wear.

- Annually: Have the press serviced by a qualified technician.

9. What are the skills and qualifications required to be a successful Strip Presser?

- High school diploma or equivalent

- Experience operating a strip press

- Knowledge of the different types of materials that can be stripped

- Understanding of the safety precautions that should be taken when operating a strip press

- Ability to troubleshoot and repair minor problems with the strip press

- Attention to detail and a commitment to quality

10. What is your experience with programming and operating CNC strip presses?

- I have experience programming and operating CNC strip presses for over 5 years.

- I am proficient in using a variety of CNC programming software, including Mastercam and SolidWorks.

- I have experience setting up and operating CNC strip presses to produce a variety of parts and components.

- I am familiar with the safety procedures for operating CNC strip presses and have a strong commitment to safety.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Strip Presser.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Strip Presser‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Strip Pressers are responsible for operating strip presses and producing a variety of metal parts. Their key job responsibilities include:

1. Machine Operation

Setting up and operating strip presses, including adjusting machine settings, loading and unloading materials.

- Ensuring that the strip press is operating safely and efficiently.

- Monitoring the production process to ensure that parts are meeting specifications.

2. Material Handling

Loading, unloading, and moving materials to and from the strip press.

- Verifying that materials meet specifications.

- Identifying and resolving any material handling issues.

3. Quality Control

Inspecting parts to ensure they meet specifications, including dimensions, surface finish, and performance.

- Identifying and correcting any defects.

- Maintaining quality control records and documentation.

4. Maintenance

Performing routine maintenance on strip presses, including lubrication, cleaning, and minor repairs.

- Identifying and reporting any major maintenance issues.

- Assisting with major maintenance and repairs.

5. Safety and Compliance

Following all safety protocols and procedures, including wearing personal protective equipment.

- Maintaining a clean and organized work area.

- Complying with all applicable environmental and safety regulations.

Interview Tips

To help you ace your interview for a Strip Presser position, consider the following tips:

1. Research the Company and Position

Take the time to learn about the company, their products and services, and the specific requirements of the Strip Presser position. This will help you tailor your answers and demonstrate your interest in the role.

- Visit the company website and social media pages.

- Read industry news and articles to stay up-to-date on the latest trends and technologies.

2. Practice Your Answers

Prepare for common interview questions by practicing your answers. This will help you feel more confident and articulate during the interview.

- Use the STAR method to structure your answers: Situation, Task, Action, Result.

- Focus on highlighting your skills and experience that are relevant to the job.

3. Be Enthousiastic and Professional

Make a good impression by being enthusiastic and professional throughout the interview. Show the interviewer that you are genuinely interested in the position and that you have the potential to be a valuable asset to the team.

- Arrive on time for your interview, dress appropriately, and maintain eye contact.

- Be polite and respectful to everyone you meet, including the receptionist and other employees.

4. Ask Questions

Asking thoughtful questions at the end of the interview demonstrates your interest and engagement. It also gives you an opportunity to clarify any details about the position or the company.

- Prepare a few questions in advance that are specific to the role or the company.

- Listen attentively to the interviewer’s answers and ask follow-up questions to show that you are engaged.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Strip Presser interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!