Are you gearing up for a career in Belt Sewer? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Belt Sewer and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

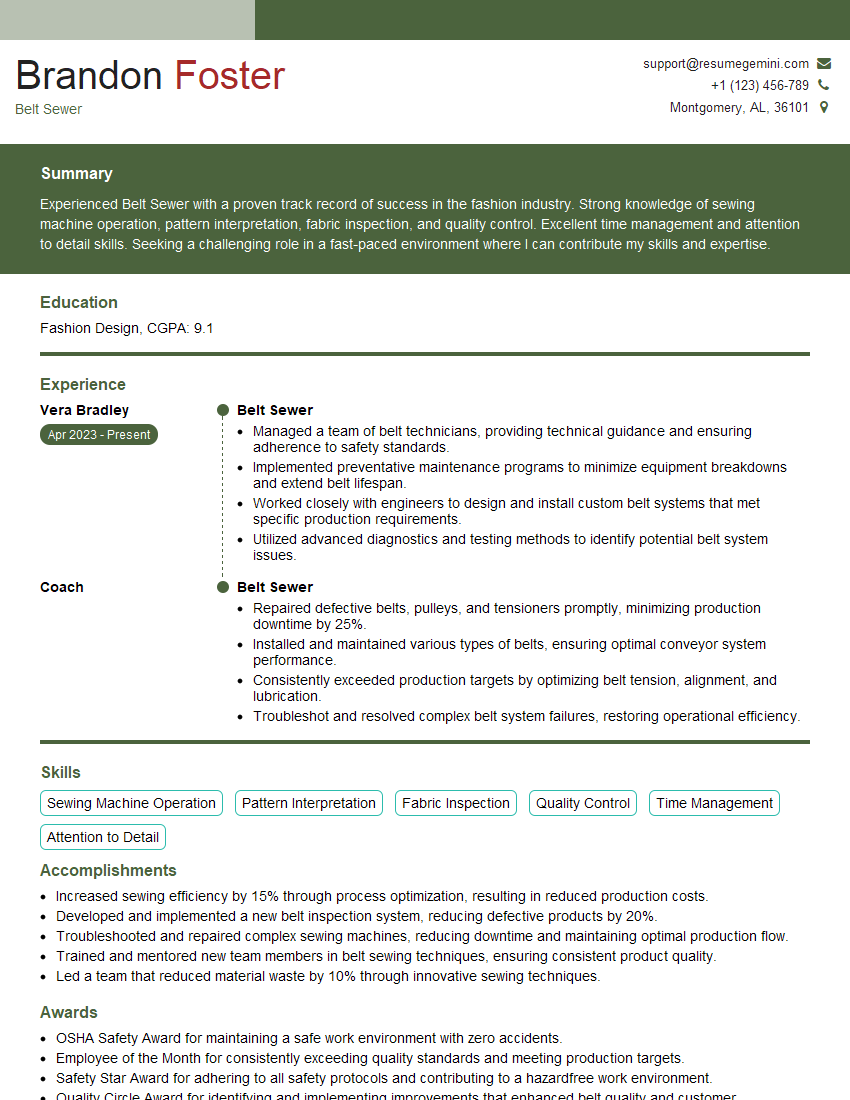

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Belt Sewer

1. Tell us about your experience in repairing and installing sewer lines?

I have over 5 years of experience in repairing and installing sewer lines. I have worked on a variety of projects, from small residential repairs to large commercial installations. I am proficient in all aspects of sewer line work, including excavation, pipe laying, and grouting.

2. What are the different types of sewer lines?

PVC

- Polyvinyl chloride (PVC) is a lightweight and durable material that is commonly used for sewer lines. It is resistant to corrosion and chemicals, and it can be easily cut and joined.

Cast Iron

- Cast iron is a strong and durable material that is often used for sewer lines in older buildings. It is resistant to corrosion and fire, but it is also heavy and expensive.

Concrete

- Concrete is a strong and durable material that is often used for sewer lines in large commercial buildings. It is resistant to corrosion and chemicals, but it is also heavy and difficult to work with.

3. What are the most common problems that you encounter with sewer lines?

- Blockages

- Leaks

- Tree root intrusion

- Corrosion

- Collapsed pipes

4. What are the different methods of repairing sewer lines?

Trenchless Repair

- Trenchless repair is a method of repairing sewer lines without having to dig a trench. This is done by inserting a liner into the pipe and then curing it in place.

Pipe Bursting

- Pipe bursting is a method of replacing a sewer line by breaking the old pipe and pulling a new pipe through the fragments.

Excavation and Replacement

- Excavation and replacement is the traditional method of repairing sewer lines. This involves digging a trench, removing the old pipe, and installing a new pipe.

5. What are the factors that you consider when choosing a repair method?

- The type of damage to the sewer line

- The location of the damage

- The cost of the repair

- The time it will take to complete the repair

6. What are the safety precautions that you take when working on sewer lines?

- Wear appropriate personal protective equipment (PPE), such as gloves, safety glasses, and a hard hat.

- Ventilate the work area to prevent the buildup of harmful gases.

- Be aware of the location of underground utilities before digging.

- Follow all safety procedures and regulations.

7. What is the importance of regular sewer line maintenance?

- Regular sewer line maintenance can help to prevent costly repairs and replacements.

- It can also help to improve the efficiency of your sewer system and prevent backups.

- Regular maintenance can also help to extend the lifespan of your sewer lines.

8. What are some tips for preventing sewer line problems?

- Do not pour grease or oil down the drain.

- Do not flush non-biodegradable items down the toilet.

- Have your sewer lines inspected and cleaned regularly.

- Be aware of the signs of sewer line problems, such as slow drains, gurgling sounds, and foul odors.

9. What are your rates for sewer line repair and installation?

My rates vary depending on the type of repair or installation needed, as well as the location and size of the project. I would be happy to provide you with a free estimate.

10. Do you offer any warranties on your work?

Yes, I offer a 1-year warranty on all of my work.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Belt Sewer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Belt Sewer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Belt Sewer is a skilled professional responsible for operating and maintaining industrial sewing machines and equipment used in the production of belts, straps, and similar products. Their primary duties include:

1. Machine Operation and Maintenance

Operate and maintain industrial sewing machines, ensuring they are in good working order and calibrated for precise stitching.

- Inspect machines regularly, identify potential issues, and perform preventative maintenance to minimize downtime.

- Clean and lubricate machines according to manufacturer’s guidelines.

- Troubleshoot and resolve machine malfunctions promptly.

2. Material Handling

Handle and prepare materials, such as leather, fabric, and thread, for sewing operations.

- Inspect materials for defects, ensure they meet specifications, and cut them to the required dimensions.

- Prepare materials for sewing by applying adhesives, marking stitching lines, and attaching accessories.

3. Sewing and Assembly

Sew and assemble belts, straps, and other products according to production specifications.

- Select appropriate threads, needles, and stitching patterns for different materials and products.

- Operate machines to stitch belts and straps with precision and accuracy.

- Inspect finished products for quality, ensuring they meet customer requirements.

4. Production Monitoring and Improvement

Monitor production processes, identify areas for improvement, and implement process changes to increase efficiency and reduce waste.

- Track production output and identify potential bottlenecks.

- Suggest process modifications to enhance productivity.

- Collaborate with production engineers to optimize sewing equipment and operations.

Interview Tips

To ace an interview for a Belt Sewer position, it is crucial to prepare thoroughly and demonstrate your technical skills and experience. Here are some tips to help you succeed:

1. Research the Company and the Role

Familiarize yourself with the company’s products, values, and industry standing. Understanding the specific responsibilities of the Belt Sewer role will help you tailor your answers to the interviewer’s questions.

- Visit the company’s website and social media pages.

- Read trade publications and industry news to gain insights into the company’s market position.

- Identify the key requirements of the job description and prepare examples that showcase your relevant skills and experience.

2. Practice Your Sewing Skills

As a Belt Sewer, your technical abilities are paramount. Consider practicing your sewing skills before the interview to demonstrate your precision and attention to detail.

- Set up a sewing machine and practice stitching different materials.

- Create a simple belt or strap to showcase your sewing capabilities.

3. Prepare Industry-Specific Questions

Show the interviewer your knowledge of the industry by preparing questions related to sewing techniques, machine maintenance, and production processes. Asking informed questions demonstrates your enthusiasm and interest in the role.

- Ask about the company’s approach to quality control.

- Inquire about their investment in new technologies or equipment.

- Show your curiosity about the company’s plans for future growth or product development.

4. Dress Professionally and Arrive on Time

First impressions matter. Dress appropriately for the interview and arrive on time to show respect for the interviewer and the company. Being punctual and well-dressed conveys your professionalism and commitment to the job.

- Choose attire that is clean, pressed, and suitable for an industrial setting.

- Be on time for your interview. Punctuality demonstrates your respect for the interviewer’s time.

5. Be Enthusiastic and Positive

Throughout the interview, maintain a positive attitude and convey your enthusiasm for the role. Your demeanor can influence the interviewer’s perception of your suitability for the position.

- Express your interest in the company and the Belt Sewer position.

- Be confident in your skills and experience, but avoid sounding arrogant.

- End the interview on a positive note, thanking the interviewer for their time and reiterating your interest in the role.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Belt Sewer, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Belt Sewer positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.