Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Cuffing Machine Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

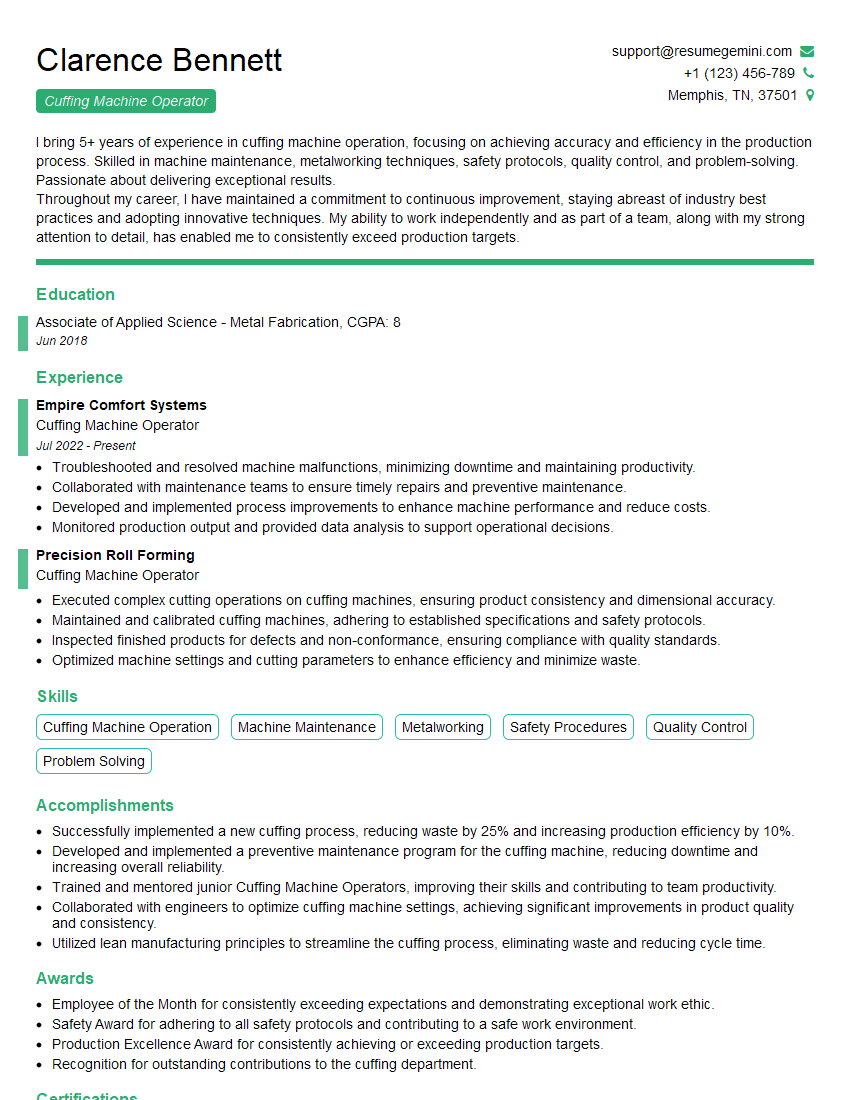

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Cuffing Machine Operator

1. Describe the process of setting up and operating a cuffing machine?

Here are the steps involved in setting up and operating a cuffing machine:

- Mount the cutting die and pressure pad on the machine.

- Set the cutting depth and pressure.

- Position the material on the cutting table.

- Activate the machine and allow the die to cut through the material.

- Remove the cut material from the machine.

2. Explain the different types of cuffing machines and their applications?

- Mechanical cuffing machines: These machines use a mechanical press to cut through the material. They are typically used for low- to medium-volume production runs.

- Hydraulic cuffing machines: These machines use a hydraulic press to cut through the material. They are more powerful than mechanical cuffing machines and can be used for high-volume production runs.

- Laser cuffing machines: These machines use a laser beam to cut through the material. They are very precise and can be used to cut complex shapes.

3. What are the safety precautions that should be taken when operating a cuffing machine?

Here are some safety precautions that should be taken when operating a cuffing machine:

- Always wear appropriate safety gear, including gloves, safety glasses, and ear protection.

- Inspect the machine before each use to ensure that it is in good working order.

- Never place your hands or fingers near the cutting die.

- Keep the cutting table clear of debris.

- Be aware of the potential for flying debris and take appropriate precautions.

4. How do you troubleshoot common problems that occur with cuffing machines?

Here are some troubleshooting tips for common problems that occur with cuffing machines:

- The machine is not cutting through the material: Check the cutting die and pressure pad for wear or damage. Also, check the cutting depth and pressure settings.

- The machine is making excessive noise: Check the machine for loose or damaged parts. Also, check the lubrication levels.

- The machine is vibrating excessively: Check the machine for loose or damaged parts. Also, check the balance of the cutting die.

5. What are your qualifications and experience in operating a cuffing machine?

I have been operating cuffing machines for the past [Number] years and have experience with a variety of different types of machines. I am proficient in setting up and operating the machines, as well as troubleshooting common problems. I have a strong safety record and am committed to following all safety procedures.

6. How do you maintain a cuffing machine?

I perform the following maintenance tasks on cuffing machines:

- Inspect the machine before each use to ensure that it is in good working order.

- Clean and lubricate the machine regularly.

- Check the cutting die and pressure pad for wear or damage and replace them as necessary.

- Follow all manufacturer’s recommended maintenance procedures.

7. What are the key factors to consider when selecting a cuffing machine for a specific application?

- The type of material being cut.

- The thickness of the material.

- The desired cutting speed.

- The production volume.

- The available budget.

8. How do you ensure the quality of the cut pieces produced by a cuffing machine?

- Inspect the cutting die and pressure pad regularly for wear or damage.

- Set the cutting depth and pressure correctly.

- Use sharp cutting dies.

- Keep the cutting table clear of debris.

9. Can you explain the difference between a shear cut and a crush cut?

- Shear cut: A shear cut is a clean, precise cut that is made by two sharp blades that slide past each other.

- Crush cut: A crush cut is a less precise cut that is made by a blunt blade that crushes the material as it cuts through it.

10. What are the advantages and disadvantages of using a cuffing machine?

Here are some advantages and disadvantages of using a cuffing machine:

Advantages:

- Cuffing machines can cut through a variety of materials.

- They can produce clean, precise cuts.

- They can be used for high-volume production runs.

Disadvantages:

- Cuffing machines can be expensive to purchase and maintain.

- They can be dangerous to operate.

- They can produce a lot of noise.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Cuffing Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Cuffing Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Cuffing Machine Operator is responsible for the operation and maintenance of cuffing machines. These machines cut and shape the ends of metal tubes or pipes to prepare them for further processing. The key job responsibilities of a Cuffing Machine Operator include:

1. Machine Operation

• Set up and operate cuffing machines according to established procedures.

• Monitor machine performance, make adjustments as needed, and ensure that the machine is operating efficiently.

• Load and unload metal tubes or pipes into and out of the machine.

• Inspect the finished product to ensure that it meets quality standards.

2. Machine Maintenance

• Perform routine maintenance on machines, such as cleaning, lubricating, and replacing worn parts.

• Identify and troubleshoot machine problems, and take corrective action.

• Keep a maintenance log and report any major issues to supervisors.

3. Quality Control

• Monitor the quality of the finished product and ensure that it meets specifications.

• Inspect incoming materials to ensure that they meet quality standards.

• Take corrective action in the event of quality issues.

4. Safety

• Follow all safety procedures and wear appropriate safety gear.

• Maintain a clean and organized work area.

• Report any safety hazards to supervisors.

Interview Tips

To ace an interview for a Cuffing Machine Operator position, it is important to be prepared and to demonstrate your knowledge and skills. Here are some interview tips:

1. Research the Company and the Position

• Visit the company website to learn about their products, services, and culture.

• Find out as much as you can about the specific position you are applying for.

• This will help you to understand what the company is looking for and to tailor your answers accordingly.

2. Practice Your Answers

• Take some time to think about the questions you are likely to be asked in an interview.

• Practice your answers to these questions out loud.

• This will help you to become more confident and articulate in your responses.

3. Highlight Your Skills and Experience

• In your answers, be sure to highlight your skills and experience that are relevant to the Cuffing Machine Operator position.

• For example, if you have experience in operating and maintaining similar machines, be sure to mention this.

• You can also highlight any special training or certifications that you have.

4. Be Enthusiastic and Positive

• Let the interviewer know that you are passionate about working as a Cuffing Machine Operator.

• Show them that you are confident in your abilities and eager to learn and grow.

• A positive attitude can go a long way in an interview.

5. Ask Questions

• At the end of the interview, be sure to ask the interviewer some questions.

• This shows that you are interested in the position and that you are taking the interview seriously.

• Some good questions to ask include:

– What is the work environment like?

– What are the expectations for this position?

– What are the opportunities for advancement?

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Cuffing Machine Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!