Are you gearing up for a career in Custom T-Shirt Embroidery Machine Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Custom T-Shirt Embroidery Machine Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

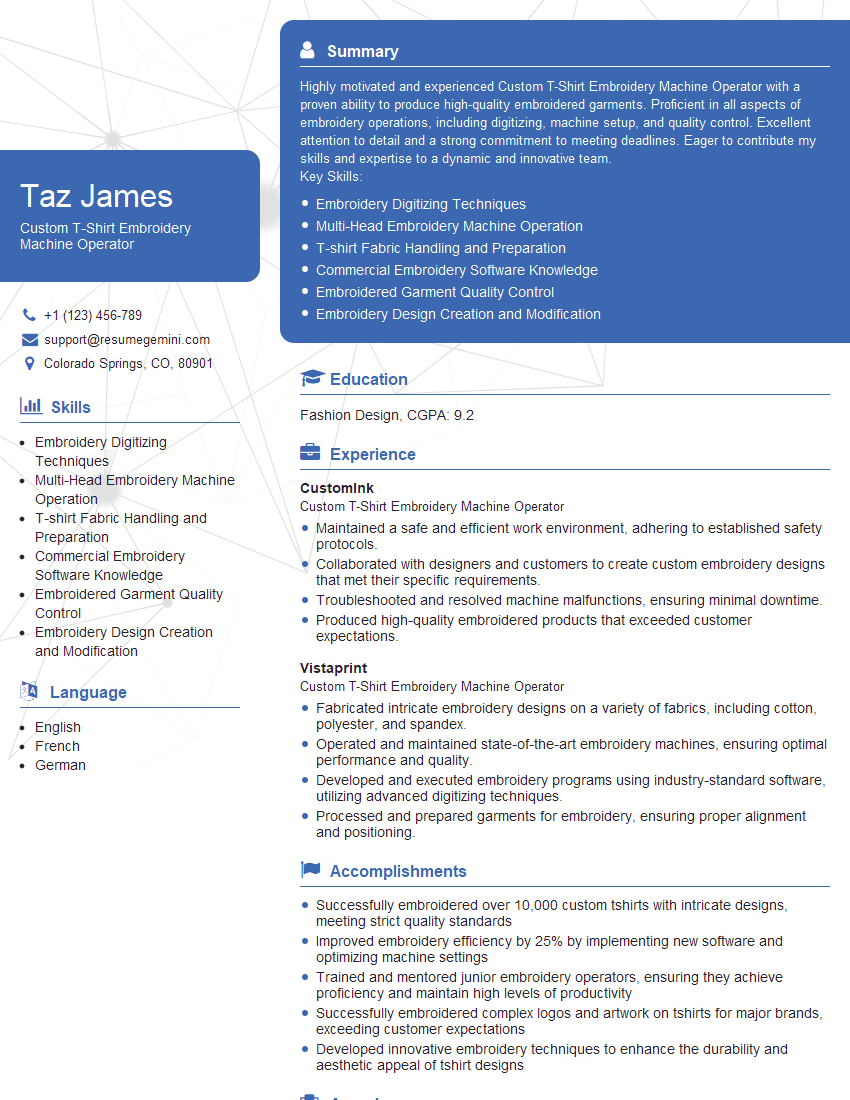

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Custom T-Shirt Embroidery Machine Operator

1. Describe the different types of embroidery machines you have worked with and what are their key features?

In my previous role, I had the opportunity to operate various types of embroidery machines, including single-needle, multi-needle, and computerized machines. Each type has its unique characteristics and capabilities:

- Single-needle machines: These machines are ideal for small-scale embroidery projects and can handle a wide range of fabrics. They offer basic stitch patterns and manual thread tension adjustment.

- Multi-needle machines: These machines feature multiple needles, allowing for faster and more complex embroidery. They are suitable for medium to large-scale projects and offer a greater variety of stitch patterns.

- Computerized machines: These machines use computer software to control embroidery designs and automate the stitching process. They offer a wide range of advanced features, such as automatic thread trimming, design editing, and color blending.

2. How do you ensure the quality of your embroidery work?

Pre-Embroidery Checks

- Inspecting fabric for any defects or irregularities.

- Checking embroidery design for any errors or missing stitches.

- Testing thread tension and adjusting it as needed.

During Embroidery

- Monitoring the embroidery process closely and making adjustments as necessary.

- Ensuring smooth thread flow and preventing any tangles or breaks.

- Inspecting the embroidery periodically for any imperfections.

Post-Embroidery Checks

- Trimming excess threads and securing loose ends.

- Inspecting the final product for any quality issues.

- Making any necessary touch-ups or repairs.

3. Explain the process of digitizing an embroidery design.

- Import the image: Import the design into a digitizing software program.

- Trace the outline: Use the tracing tools to outline the main shapes and contours of the design.

- Set the stitch parameters: Determine the types of stitches, stitch density, and thread colors for different areas of the design.

- Create the underlay: Establish a foundation of stitches to support the top stitches.

- Test the design: Embroider a sample to ensure the accuracy and quality of the digitized design.

4. How do you handle complex embroidery designs with multiple colors and intricate details?

- Carefully plan the embroidery sequence: Determine the order in which different colors and design elements will be stitched.

- Use appropriate needles and threads: Select needles and threads that are suitable for the specific fabrics and design details.

- Adjust thread tension and stitch settings: Optimize these settings to ensure proper stitch quality and prevent fabric puckering or thread breakage.

- Monitor the embroidery process closely: Pay attention to any potential issues and make necessary adjustments to maintain the accuracy and detail of the design.

5. What are the common challenges you have faced while operating an embroidery machine and how did you resolve them?

Challenge 1: Thread Breaks

- Cause: Incorrect thread tension, dull needle, fabric snags.

- Resolution: Adjusted thread tension, replaced needle, trimmed fabric.

Challenge 2: Puckering or Rippling

- Cause: Too much thread tension, unstable fabric.

- Resolution: Reduced thread tension, used stabilizer.

Challenge 3: Misaligned Stitches

- Cause: Loose machine parts, incorrect hooping.

- Resolution: Tightened machine parts, re-hooped the fabric.

6. How do you troubleshoot and maintain an embroidery machine?

Troubleshooting

- Identify the issue: Observe the machine’s behavior, check the error messages, and inspect the physical components.

- Refer to the user manual: Consult the manufacturer’s instructions for specific troubleshooting steps.

- Perform basic checks: Ensure proper power supply, needle and thread alignment, and lubrication.

- Seek professional assistance: Contact an experienced technician for complex issues or repairs.

Maintenance

- Regular cleaning: Remove dust, lint, and thread remnants from the machine.

- Lubrication: Apply lubrication to moving parts as per the manufacturer’s recommendations.

- Needle replacement: Replace dull or damaged needles to prevent thread breaks and poor stitch quality.

- Software updates: Install software updates to ensure optimal performance and bug fixes.

7. What is the importance of maintaining proper hoop tension when embroidering?

- Prevents fabric distortion: Proper tension keeps the fabric taut, preventing puckering or stretching during embroidery.

- Ensures stitch quality: Stable fabric allows for precise stitch placement and prevents skipped or misaligned stitches.

- Reduces thread breakage: Excessive tension can cause thread snapping, while insufficient tension can lead to loose stitches.

- Protects the machine: Properly tensioned fabric minimizes stress on the machine’s components, reducing wear and tear.

8. How do you ensure consistent color matching in your embroidery work?

- Use high-quality threads: Choose threads that are colorfast and resistant to fading.

- Calibrate the machine: Fine-tune the machine settings to ensure accurate color reproduction.

- Test thread colors: Embroider small samples to verify the color match before starting a project.

- Maintain thread inventory: Keep a record of thread colors used to ensure consistency in future projects.

9. Describe your experience with different types of fabrics and how you adjust your embroidery settings accordingly.

- Delicate fabrics (e.g., silk, chiffon): Use fine needles, low thread tension, and delicate stitches to prevent fabric damage.

- Medium-weight fabrics (e.g., cotton, linen): Adjust thread tension and stitch density to achieve a balanced and durable embroidery.

- Thick fabrics (e.g., denim, leather): Use heavier needles, higher thread tension, and larger stitch sizes to accommodate the fabric’s thickness.

10. How do you stay up-to-date with the latest embroidery techniques and industry trends?

- Attend industry workshops and seminars: Participate in educational events to learn about new techniques and advancements.

- Subscribe to embroidery magazines and online forums: Stay informed about industry news, product releases, and best practices.

- Follow embroidery artists and designers on social media: Get inspiration and connect with professionals to exchange knowledge.

- Experiment with different materials and techniques: Dedicate time to explore new ideas and push the boundaries of your embroidery skills.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Custom T-Shirt Embroidery Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Custom T-Shirt Embroidery Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Custom T-Shirt Embroidery Machine Operators are responsible for the efficient and precise operation of embroidery machines to create custom designs on t-shirts.

1. Machine Operation

Operate and maintain embroidery machines to produce high-quality embroidered designs on t-shirts.

- Set up and adjust machine parameters according to design specifications.

- Load and unload t-shirts and ensure proper positioning for embroidery.

2. Design Interpretation

Interpret and convert digital design files into machine-readable formats.

- Identify and resolve any potential issues with designs before embroidery.

- Fine-tune designs to optimize embroidery quality and efficiency.

3. Thread Management

Manage and maintain a variety of embroidery threads and supplies.

- Select and change threads based on design requirements.

- Monitor thread tension and adjust as needed to prevent breakage.

4. Quality Control

Inspect embroidered t-shirts for defects and ensure they meet quality standards.

- Identify and correct any errors or imperfections in embroidery.

- Maintain accurate records of embroidery production and quality.

5. Troubleshooting

Troubleshoot and resolve machine malfunctions and embroidery issues.

- Diagnose problems and implement solutions to minimize downtime.

- Collaborate with maintenance technicians for major repairs.

Interview Tips

To ace an interview for a Custom T-Shirt Embroidery Machine Operator position, candidates should prepare thoroughly and demonstrate their skills and experience.

1. Research the Company and Role

Familiarize yourself with the company’s products, services, and culture.

- Review the job description carefully and highlight your relevant qualifications.

- Prepare specific examples of your experience that demonstrate your skills in embroidery machine operation.

2. Practice Machine Operation

If possible, practice operating an embroidery machine before the interview.

- This will demonstrate your familiarity with the equipment and your ability to operate it confidently.

- You can also highlight your knowledge of different embroidery techniques and materials.

3. Prepare for Competency Questions

Prepare answers to common competency questions that may be asked during the interview.

- Describe a time when you had to troubleshoot a problem with an embroidery machine.

- Explain how you ensure the quality of your embroidered products.

- Share an example of a design challenge you faced and how you overcame it.

4. Be Enthusiastic and Professional

Show your enthusiasm for the role and the embroidery industry.

- Dress professionally and arrive on time for your interview.

- Be confident in your abilities and demonstrate your willingness to learn and grow.

5. Ask Questions

At the end of the interview, ask thoughtful questions to show your engagement and interest in the position.

- Inquire about the company’s training and development opportunities.

- Ask about the company’s commitment to quality and customer satisfaction.

- Thank the interviewer for their time and consideration.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Custom T-Shirt Embroidery Machine Operator, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Custom T-Shirt Embroidery Machine Operator positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.