Are you gearing up for a career in Flap Maker? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Flap Maker and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

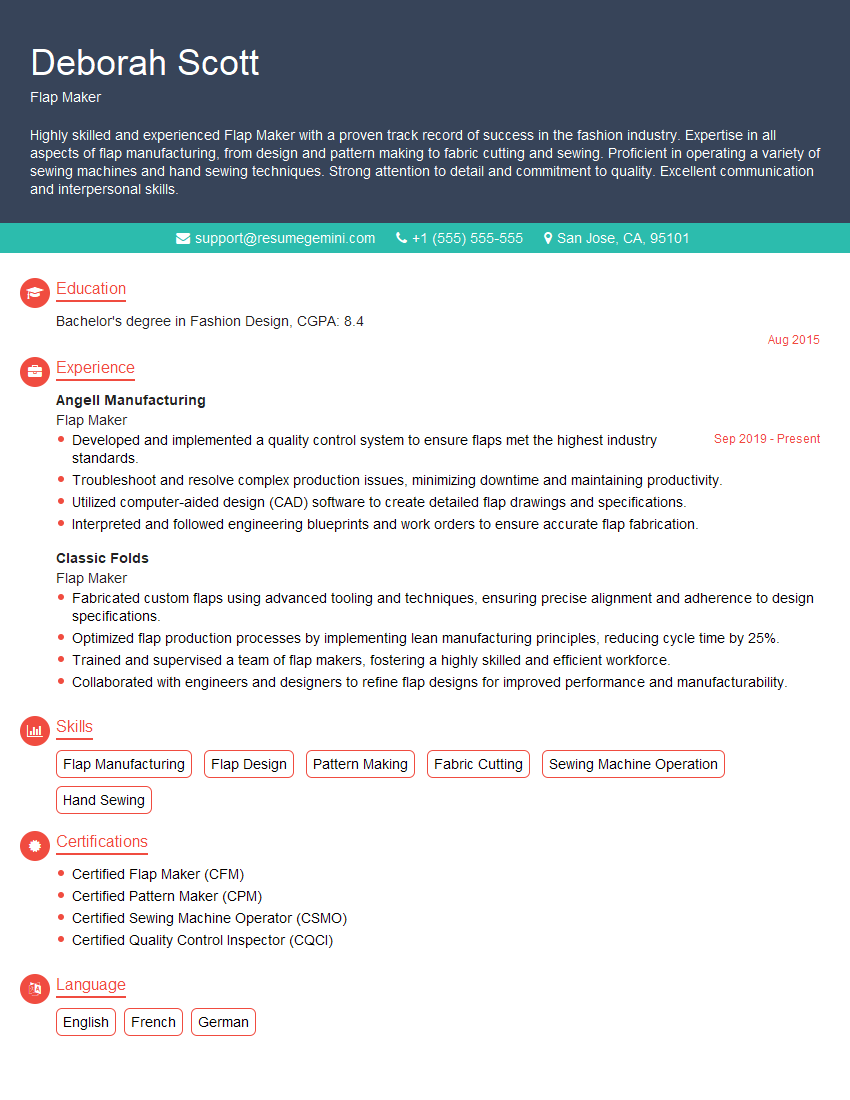

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Flap Maker

1. What are the different types of flaps and their functions?

- Plain flaps: Increase lift and drag, used for takeoff and landing.

- Split flaps: Increase lift more than plain flaps, less drag, used for takeoff and landing.

- Fowler flaps: Similar to split flaps but extend backward, increasing wing area and lift.

- Aileron flaps: Act as ailerons and flaps, providing roll control and increased lift.

2. Explain the process of flap fabrication, from material selection to final assembly.

Material Selection

- Consider factors such as strength, weight, corrosion resistance, and cost.

- Common materials include aluminum alloys, composite materials, and titanium.

Manufacturing

- Involve cutting, forming, joining, and finishing processes.

- Methods include machining, stamping, hydroforming, and welding.

Assembly

- Involves assembling individual components, such as spars, ribs, and skins.

- Requires precision alignment and secure fastening.

Inspection and Testing

- Ensure flap meets design specifications and safety standards.

- Involve visual inspections, dimensional measurements, and load testing.

3. What are the key factors to consider when designing flaps for specific aircraft applications?

- Aircraft type and performance requirements

- Lift and drag characteristics

- Structural integrity and weight

- Environmental conditions

- Maintenance and durability

4. Describe the role of composite materials in flap design and how they impact flap performance.

- Strength-to-weight ratio: Composites are lighter and stronger than traditional materials.

- Improved fatigue resistance: Composites can withstand repeated stress cycles better.

- Tailorability: Composites can be customized to meet specific performance requirements.

- Reduced maintenance: Composites are corrosion-resistant and require less maintenance.

5. Explain the use of computational fluid dynamics (CFD) in analyzing and optimizing flap performance.

- CFD simulates airflow around flaps.

- Analyzes lift, drag, and other performance parameters.

- Optimizes flap shape and design for improved efficiency.

- Reduces the need for physical testing.

6. Describe the different types of flap control systems and their advantages and disadvantages.

- Direct link between pilot inputs and flap movement.

- Simple and reliable, but limited in complexity.

- Use hydraulic pressure to actuate flaps.

- Provide more precise control and higher flap loads.

- Use electric motors and actuators to move flaps.

- Lightweight, efficient, and offer advanced control features.

Mechanical control systems

Hydraulic control systems

Electric control systems

7. Explain the importance of flap maintenance and inspection for aircraft safety and performance.

- Prevent malfunctions and failures.

- Extend flap lifespan and reduce maintenance costs.

- Ensure optimal aircraft performance and safety.

- Detect and address any damage or deterioration.

8. Describe the challenges and considerations in designing flaps for high-speed aircraft.

- Managing aerodynamic loads and pressure gradients.

- Mitigating flutter and other structural issues.

- Optimizing flap performance at different speeds.

- Ensuring structural integrity under extreme conditions.

9. What are the latest advancements and research directions in flap design and technology?

- Smart flaps with adaptive control systems.

- Use of advanced materials and manufacturing techniques.

- CFD and simulation for optimizing flap performance.

- Biomimetic designs inspired by natural flight.

10. How can flap design contribute to improving aircraft fuel efficiency and reducing environmental impact?

- Optimized lift-to-drag ratio reduces fuel consumption.

- Lightweight flaps reduce aircraft weight.

- Composite materials reduce maintenance and replacement costs.

- Advanced control systems enable precise flap operation for better efficiency.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Flap Maker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Flap Maker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Flap makers are skilled craftspeople who build and repair aircraft flaps. They work closely with engineers and other members of the aircraft manufacturing team to ensure that the flaps meet the required specifications. Key job responsibilities of a flap maker include:

1. Fabricate and Assemble Flaps

Flap makers use a variety of materials to fabricate and assemble flaps, including metal, composite materials, and plastics. They use specialized tools and equipment to cut, shape, and join the materials together. Flap makers must have a strong understanding of the principles of aerodynamics and engineering in order to ensure that the flaps are built to the correct specifications.

2. Inspect and Test Flaps

Flap makers are responsible for inspecting and testing flaps to ensure that they meet the required quality standards. They use a variety of non-destructive testing (NDT) methods to check for defects in the materials and workmanship. Flap makers must also conduct functional tests to ensure that the flaps operate properly.

3. Repair and Maintain Flaps

Flap makers are responsible for repairing and maintaining flaps throughout their service life. They use a variety of techniques to repair damaged flaps, including welding, riveting, and patching. Flap makers must also perform regular maintenance on flaps to ensure that they continue to operate properly.

4. Work with Engineers and Other Team Members

Flap makers work closely with engineers and other members of the aircraft manufacturing team to ensure that the flaps meet the required specifications. They may also be involved in the design and development of new flap systems.

Interview Tips

To ace an interview for a flap maker position, candidates should be prepared to discuss their skills and experience in the following areas:

1. Fabrication and Assembly

Candidates should be familiar with the materials and techniques used in the fabrication and assembly of aircraft flaps. They should also be able to demonstrate their skills in using specialized tools and equipment.

2. Inspection and Testing

Candidates should be familiar with the NDT methods used to inspect flaps for defects. They should also be able to demonstrate their skills in conducting functional tests to ensure that the flaps operate properly.

3. Repair and Maintenance

Candidates should be familiar with the techniques used to repair and maintain aircraft flaps. They should also be able to demonstrate their skills in performing regular maintenance on flaps.

4. Teamwork and Communication

Candidates should be able to demonstrate their ability to work effectively with engineers and other members of the aircraft manufacturing team. They should also be able to communicate clearly and concisely.

5. Safety

Candidates should be familiar with the safety regulations that apply to the aircraft manufacturing industry. They should also be able to demonstrate their commitment to safety in the workplace.

Example Outline for Answering an Interview Question:

- Introduction: Briefly state your name and the position you are applying for.

- Experience: Describe your relevant experience in the field, including your skills and accomplishments.

- Qualifications: Explain how your qualifications meet the requirements of the position.

- Example: Provide a specific example of a time when you successfully completed a task that is relevant to the position.

- Conclusion: Summarize your key skills and experience, and reiterate your interest in the position.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Flap Maker, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Flap Maker positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.