Are you gearing up for an interview for a Flat Lock Machine Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Flat Lock Machine Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

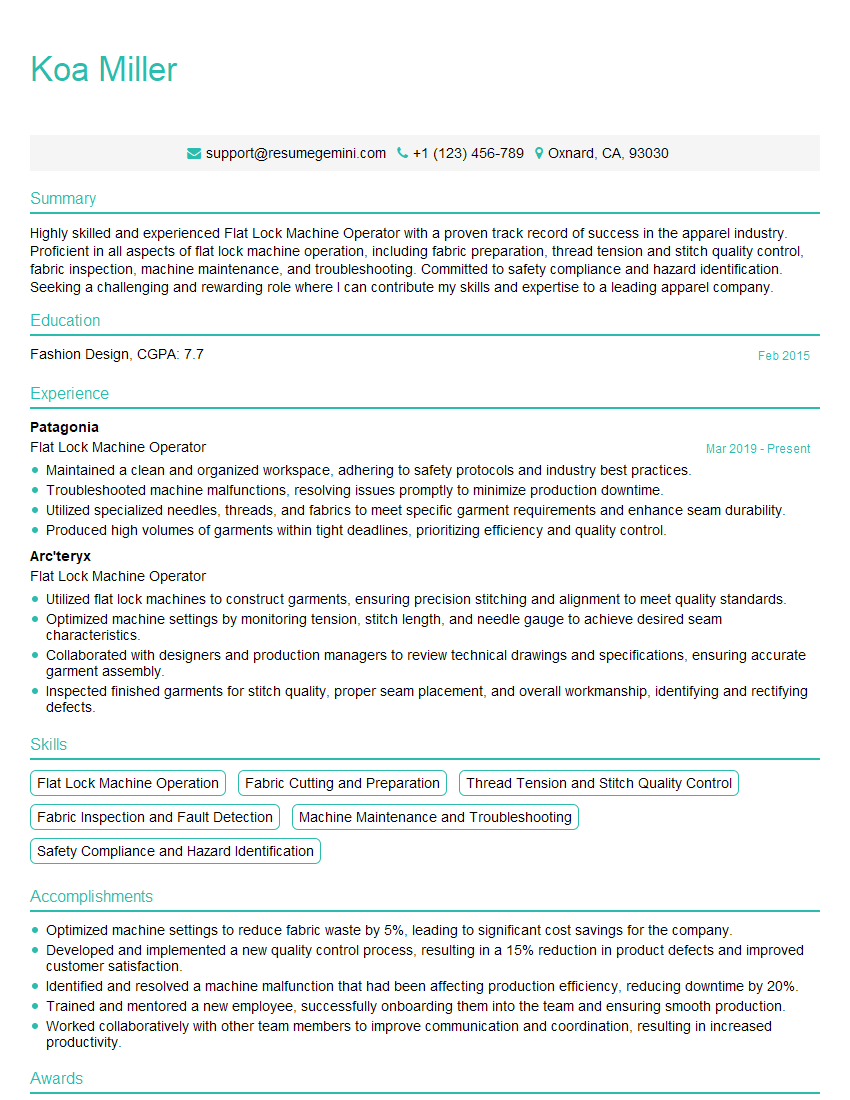

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Flat Lock Machine Operator

1. What are the different types of flat lock machines?

Flat lock machines can be classified into two main types: single-needle flat lock machines and double-needle flat lock machines. Single-needle flat lock machines use a single needle to create a flat lock stitch, while double-needle flat lock machines use two needles to create a more durable and secure stitch.

2. What are the main differences between a flat lock stitch and a regular stitch?

Advantages of flat lock stitch:

- Stronger and more durable

- More elastic

- Less likely to unravel

Advantages of regular stitch:

- Faster to sew

- Less expensive

- More versatile

3. What are the most important factors to consider when setting up a flat lock machine?

- The type of fabric being sewn

- The desired stitch length and width

- The tension of the thread

- The speed of the machine

4. How do you troubleshoot common problems with flat lock machines?

Here a few common problems and their fixes:

- Skipped stitches: Check the tension of the thread, the needle, and the bobbin.

- Broken thread: Check the tension of the thread, the needle, and the bobbin.

- Puckering: Check the tension of the thread, the stitch length, and the presser foot pressure.

5. What are the safety precautions that must be taken when operating a flat lock machine?

- Always wear safety glasses.

- Keep your hands away from the needle.

- Do not operate the machine if it is damaged.

- Unplug the machine before making any adjustments.

6. What are the different types of seams that can be sewn with a flat lock machine?

- Flat lock seam

- Mock flat lock seam

- Overlock seam

- Coverstitch seam

7. What are the different applications of flat lock machines?

- Sewing activewear

- Sewing swimwear

- Sewing lingerie

- Sewing medical garments

8. What are the advantages and disadvantages of using a flat lock machine?

Advantages:

- Strong and durable seams

- Elastic seams

- Less likely to unravel

Disadvantages:

- Slower to sew than regular sewing machines

- More expensive than regular sewing machines

- Less versatile than regular sewing machines

9. What is the difference between a differential feed and a regular feed?

A differential feed is a type of feed system that allows the fabric to be fed at different rates. This is useful for sewing seams that require different amounts of stretch, such as seams in activewear.

10. What are the different types of thread that can be used with a flat lock machine?

- Polyester thread

- Nylon thread

- Cotton thread

- Spun polyester thread

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Flat Lock Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Flat Lock Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Flat Lock Machine Operators are responsible for the safe and efficient operation of flat lock machines, which are used to sew fabrics together. Key job responsibilities of a Flat Lock Machine Operator include:

1. Operation of flat lock machine

Following written and verbal work orders, the flat lock machine operator sets up and operates flat lock machines. They also monitor the machine’s operation, making adjustments as needed to ensure that the machine is running smoothly and producing quality seams.

2. Threading of machine

The flat lock machine operator is also responsible for threading the machine with the correct type and color of thread. They must also be able to troubleshoot and correct any problems that may arise with the machine’s threading.

3. Fabric handling

Flat lock machine operators must be able to handle fabrics of all types and weights. They must be able to load and unload fabrics from the machine, as well as position and guide the fabric during sewing.

4. Quality control

Flat lock machine operators are responsible for the quality of the seams that they produce. They must be able to inspect seams for defects and make any necessary adjustments to ensure that the seams meet the required standards.

Interview Tips

In addition to preparing for the technical aspects of the interview, there are several other things that candidates can do to increase their chances of success.

1. Research the company and the position

Before the interview, it is important for candidates to research the company and the position they are applying for. This will help them to understand the company’s culture and values, as well as the specific requirements of the position. Candidates can research the company’s website, read news articles, and talk to people who work at the company.

2. Practice answering common interview questions

There are a number of common interview questions that candidates can expect to be asked, such as “Tell me about yourself” and “Why are you interested in this position?”. It is helpful to practice answering these questions in advance so that candidates can deliver their answers confidently and concisely.

3. Prepare questions to ask the interviewer

Asking the interviewer questions at the end of the interview shows that candidates are interested in the position and the company. It also gives candidates an opportunity to learn more about the company and the position. Some good questions to ask include “What are the biggest challenges facing the company right now?” and “What are the opportunities for advancement within the company?”.

4. Dress professionally and arrive on time for the interview

First impressions matter, so it is important for candidates to dress professionally and arrive on time for the interview. This shows that candidates are respectful of the interviewer’s time and that they are serious about the position.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Flat Lock Machine Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!