Feeling lost in a sea of interview questions? Landed that dream interview for Flat Locker but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Flat Locker interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

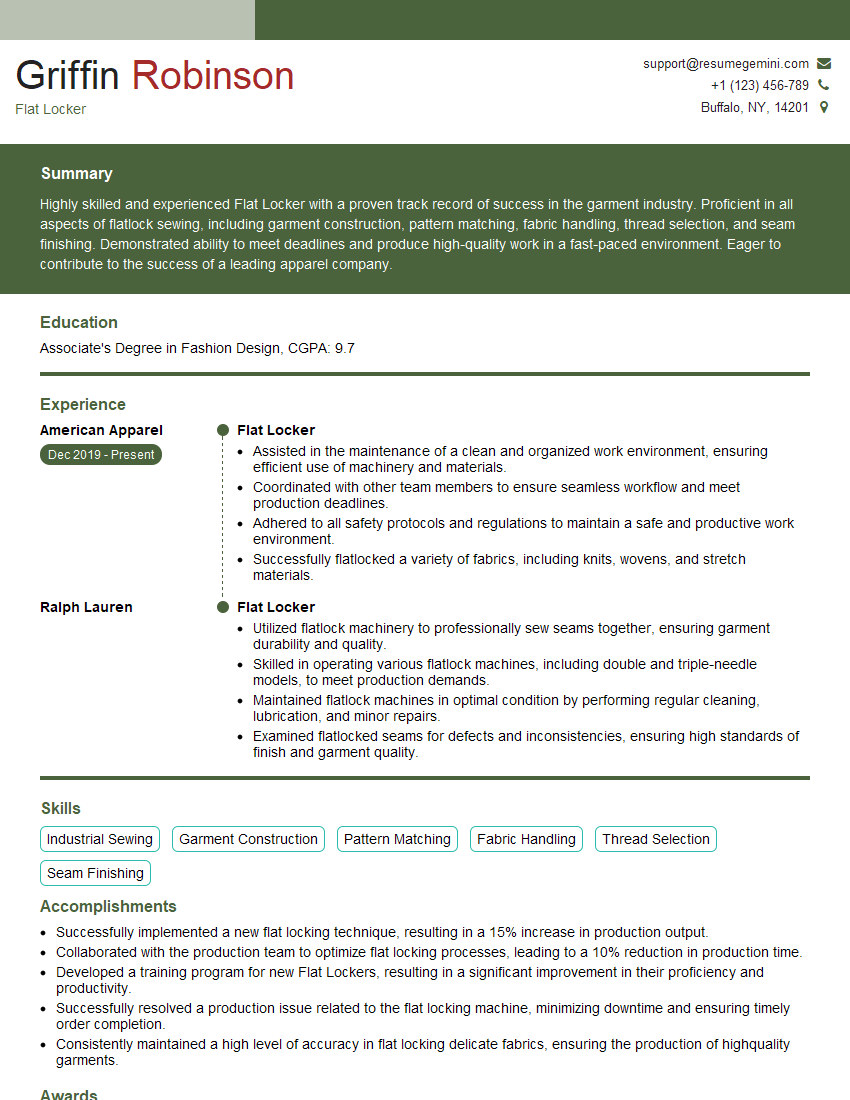

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Flat Locker

1. Explain the process of setting up a flat locker machine?

- Inspect the machine and its components for any damage or wear.

- Clean and lubricate the machine according to the manufacturer’s instructions.

- Install the needles and thread the machine according to the fabric being used.

- Adjust the machine settings for stitch length, tension, and feed rate.

- Test the machine by sewing a sample piece of fabric to ensure proper operation.

2. What are the different types of seams that can be sewn on a flat locker machine?

Overlock seam

- Used to finish the edges of fabric to prevent fraying.

- Creates a stitch that wraps around the edge of the fabric, securing it in place.

Flatlock seam

- Used to create a strong and stretchy seam that is often used in activewear and swimwear.

- Creates a stitch that is flat and parallel to the edge of the fabric.

3. How do you troubleshoot common problems with a flat locker machine?

- Broken needle: Replace the needle with a new one.

- Thread breakage: Check the thread tension and re-thread the machine if necessary.

- Puckering: Adjust the stitch length or tension.

- Skipped stitches: Clean the machine and oil the moving parts.

- Uneven stitches: Check the needle and make sure it is properly installed.

4. What are the safety precautions that should be taken when operating a flat locker machine?

- Wear appropriate safety gear, including safety glasses and earplugs.

- Keep hands away from moving parts.

- Do not operate the machine if it is damaged.

- Unplug the machine before performing any maintenance or repairs.

- Follow all manufacturer’s instructions for safe operation.

5. How do you maintain a flat locker machine to ensure optimal performance?

- Clean the machine regularly to remove dust and lint.

- Lubricate the moving parts according to the manufacturer’s instructions.

- Inspect the needles and replace them as needed.

- Check the thread tension and adjust as necessary.

- Store the machine in a dry place when not in use.

6. What are the different types of fabrics that can be sewn on a flat locker machine?

- Knits

- Wovens

- Stretch fabrics

- Denim

- Leather

7. What is the difference between a flat locker machine and a serger?

- Flat locker machines create a flat stitch that is parallel to the edge of the fabric.

- Sergers create an overlock stitch that wraps around the edge of the fabric.

- Flat locker machines are typically used for heavier fabrics, while sergers are used for lighter fabrics.

8. What are the advantages of using a flat locker machine?

- Creates a strong and stretchy seam.

- Produces a flat and professional-looking finish.

- Can be used on a variety of fabrics.

- Relatively easy to operate.

9. What are the challenges of using a flat locker machine?

- Can be difficult to thread.

- Requires precise adjustment to achieve the desired stitch quality.

- Can be noisy and vibrate.

10. How do you determine the correct needle size for a flat locker machine?

- Consider the fabric weight and thickness.

- Refer to the manufacturer’s recommendations.

- Test different needle sizes to find the one that produces the best stitch quality.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Flat Locker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Flat Locker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Flat Locker holds the paramount responsibility of operating flat locking machines to join various fabric pieces into finished garments or other textile products. The role demands proficiency in handling industrial sewing equipment and adhering to established production standards for quality output.

1. Fabric Handling and Preparation

The Flat Locker meticulously checks fabric panels for defects, ensuring their suitability for the production process. They deftly spread out the fabric, aligning and positioning it precisely on the machine bed for accurate stitching.

2. Machine Operation and Adjustment

With a keen eye for detail, the Flat Locker expertly operates and fine-tunes flat locking machines. They adjust settings such as thread tension, stitch length, and differential feed to achieve optimal seam quality and efficiency.

3. Seam Creation and Finishing

Using a combination of overlock and cover stitches, the Flat Locker seamlessly joins fabric panels, creating durable and aesthetically pleasing seams. They ensure uniform stitch quality throughout the garment or product, maintaining high production standards.

4. Quality Control and Inspection

The Flat Locker diligently inspects completed seams for any irregularities or defects. They assess stitch quality, tension, and seam strength to ensure products meet established specifications and customer requirements.

Interview Tips

To ace your interview for a Flat Locker position, follow these invaluable tips and hacks:

1. Research the Company and Position

Take the time to thoroughly research the company and the specific Flat Locker role you’re applying for. Demonstrate your interest and understanding by asking insightful questions during the interview.

2. Highlight Your Technical Skills

Emphasize your proficiency in operating flat locking machines and your ability to handle diverse fabrics. Share examples of your experience in adjusting machine settings and troubleshooting any potential issues.

3. Showcase Your Quality Assurance Mind

Convey your meticulous attention to detail and strong commitment to quality standards. Highlight your ability to conduct thorough inspections and identify any seam imperfections that may occur during production.

4. Prepare for Common Interview Questions

Anticipate and prepare for common interview questions such as:

- “Tell us about your experience in flat locking operations.”

- “Describe a time you had to troubleshoot a machine issue.”

- “How do you ensure the quality of your seams?”

5. Be Enthusiastic and Professional

Convey your enthusiasm for the role and the company. Maintain a positive and professional demeanor throughout the interview, demonstrating your eagerness to learn and contribute to the team.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Flat Locker interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.