Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Flatlock Sewing Machine Operator interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Flatlock Sewing Machine Operator so you can tailor your answers to impress potential employers.

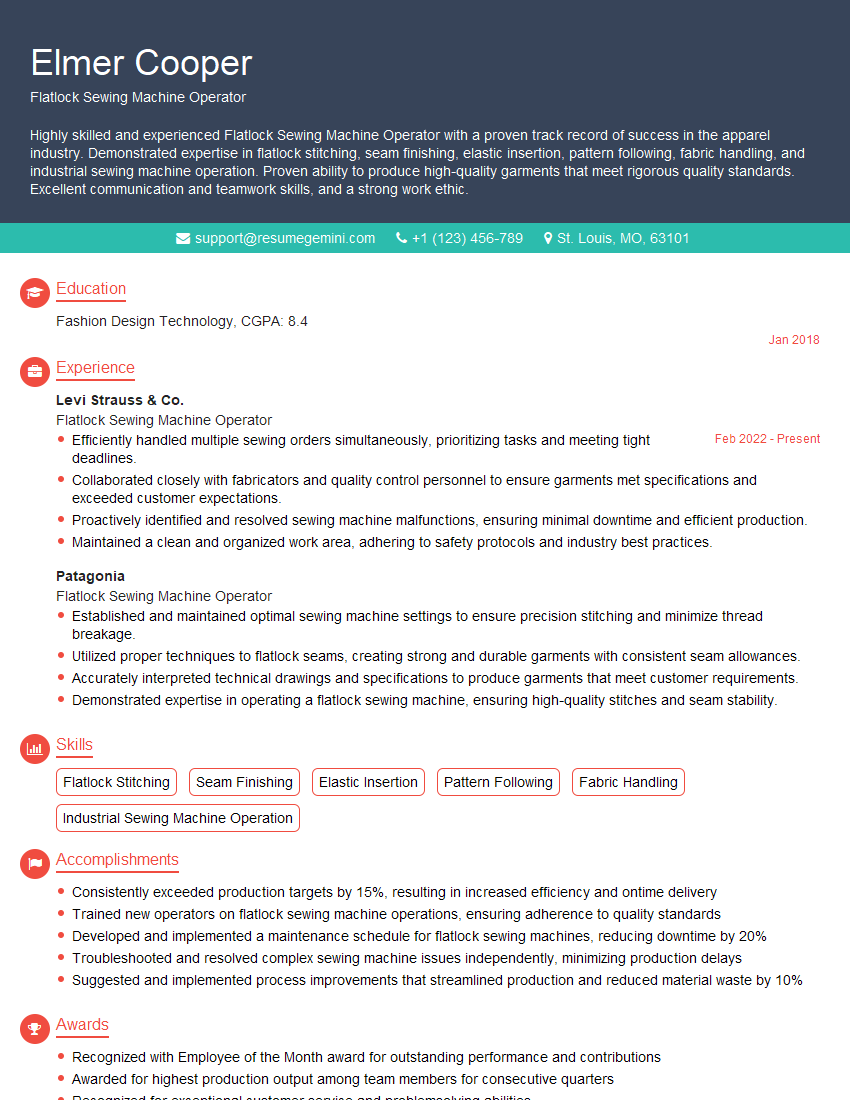

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Flatlock Sewing Machine Operator

1. How do you set up and adjust a flatlock sewing machine?

To set up and adjust a flatlock sewing machine, I typically follow these steps:

- Place the machine on a stable surface and ensure it is level.

- Thread the machine with the appropriate thread according to the manufacturer’s instructions.

- Adjust the tension of the threads to achieve the desired stitch quality.

- Set the stitch length and width according to the fabric and seam requirements.

- Mount the fabric onto the machine and align it properly.

2. What is the difference between a flatlock seam and a regular seam?

Structure

- Flatlock seams have a unique three-thread construction.

- Regular seams typically use two threads.

Appearance

- Flatlock seams have a flat and decorative appearance.

- Regular seams are less visible and more commonly used for hidden seams.

Applications

- Flatlock seams are often used in athletic wear and swimwear due to their durability and flexibility.

- Regular seams are used in a wider variety of applications.

3. What types of fabrics are suitable for flatlock sewing?

Flatlock sewing is suitable for a wide range of fabrics, including:

- Knits, such as cotton, jersey, and fleece

- Wovens, like denim and chambray

- Stretch fabrics, including spandex and Lycra

- Synthetic fabrics, such as nylon and polyester

4. How do you maintain a flatlock sewing machine?

To maintain a flatlock sewing machine, I regularly perform the following tasks:

- Clean the machine head and remove any lint or thread residue.

- Oil the moving parts according to the manufacturer’s instructions.

- Inspect the needles for wear and replace them as needed.

- Check the tension of the threads and adjust as necessary.

- Troubleshoot any issues and make repairs as required.

5. What safety precautions should be taken when operating a flatlock sewing machine?

To ensure safety when operating a flatlock sewing machine, I adhere to the following precautions:

- Wear appropriate safety gear, including eye protection and gloves.

- Keep the work area tidy and free of tripping hazards.

- Secure the fabric firmly to the machine to prevent it from bunching.

- Do not operate the machine if it is damaged or malfunctioning.

- Follow all manufacturer’s instructions and safety guidelines.

6. What is your experience with different types of flatlock machines?

I have experience working with various types of flatlock machines, including:

- Juki MO series

- Union Special 43700

- Consew 227RT

Each type offers different features and capabilities, and I have become proficient in using them for different applications.

7. Can you describe a challenging flatlock project you have worked on?

One challenging flatlock project I worked on was sewing a custom-designed sportswear garment. The fabric was a delicate knit that required careful handling and precise stitching to achieve the desired aesthetic and functionality.

8. How do you ensure the quality of your flatlock seams?

I ensure the quality of my flatlock seams by:

- Inspecting the fabric and adjusting the machine settings accordingly.

- Using high-quality thread and needles.

- Maintaining a clean and well-maintained machine.

- Continuously monitoring the stitching process and making adjustments as needed.

- Performing quality checks on the finished seams to meet the required standards.

9. What are the industry standards for flatlock seams?

The industry standards for flatlock seams include:

- Stitch length: Typically between 2.5 and 3.5 mm

- Seam width: Usually between 5 and 8 mm

- Overlap: Approximately 50%

- Thread tension: Adjusted according to the fabric and thread type

- Stitch quality: Consistent, secure, and free from defects

10. How do you stay updated with the latest advancements in flatlock sewing technology?

To stay updated with the latest advancements in flatlock sewing technology, I engage in the following activities:

- Attending industry trade shows and conferences.

- Reading industry publications and online resources.

- Consulting with equipment manufacturers and suppliers.

- Participating in online forums and discussions.

- Seeking professional development opportunities and training.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Flatlock Sewing Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Flatlock Sewing Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Flatlock Sewing Machine Operators are responsible for operating and maintaining flatlock sewing machines to sew and finish seams on garments and other textile products. They must be able to follow instructions, work independently, and meet production goals. Key job responsibilities include:

1. Operating Flatlock Sewing Machines

Flatlock Sewing Machine Operators must be able to properly operate and maintain flatlock sewing machines. This includes threading the machine, adjusting tension, and setting stitch length. They must also be able to troubleshoot and repair minor machine problems.

2. Sewing and Finishing Seams

Flatlock Sewing Machine Operators sew and finish seams on garments and other textile products. They must be able to sew straight seams, curved seams, and corners. They must also be able to sew on different types of fabrics, including knits, wovens, and stretch fabrics.

3. Meeting Production Goals

Flatlock Sewing Machine Operators must be able to meet production goals. This means sewing a certain number of seams per hour or day. They must also be able to maintain quality standards.

4. Following Instructions

Flatlock Sewing Machine Operators must be able to follow instructions. They must be able to read and understand work orders and instructions from supervisors. They must also be able to ask questions when they do not understand something.

5. Working Independently

Flatlock Sewing Machine Operators often work independently. They must be able to manage their own time and work without constant supervision.

Interview Tips

Preparing for an interview can be daunting, but there are a few things you can do to increase your chances of success. Here are some interview tips for Flatlock Sewing Machine Operators:

1. Research the Company

Before your interview, take some time to research the company you are applying to. This will help you understand their culture, values, and what they are looking for in a Flatlock Sewing Machine Operator. You can find this information on the company’s website, social media pages, and Glassdoor.

2. Practice Your Answers

Once you have researched the company, take some time to practice your answers to common interview questions. This will help you feel more confident and prepared during your interview. Some common interview questions for Flatlock Sewing Machine Operators include:

- Tell me about your experience operating flatlock sewing machines.

- How do you meet production goals while maintaining quality standards?

- What are your strengths and weaknesses as a Flatlock Sewing Machine Operator?

3. Dress Professionally

First impressions matter, so it is important to dress professionally for your interview. This means wearing clean, pressed clothes that are appropriate for the workplace. You should also avoid wearing excessive jewelry or makeup.

4. Be Punctual

Punctuality is important for any interview, but it is especially important for manufacturing jobs. Make sure to arrive at your interview on time, or even a few minutes early. This will show the interviewer that you are respectful of their time.

5. Be Yourself

The most important thing is to be yourself during your interview. The interviewer wants to get to know the real you, so don’t try to be someone you’re not. Just relax, be confident, and let your personality shine through.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Flatlock Sewing Machine Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.