Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Lockstitch Front Edge Tape Sewer interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Lockstitch Front Edge Tape Sewer so you can tailor your answers to impress potential employers.

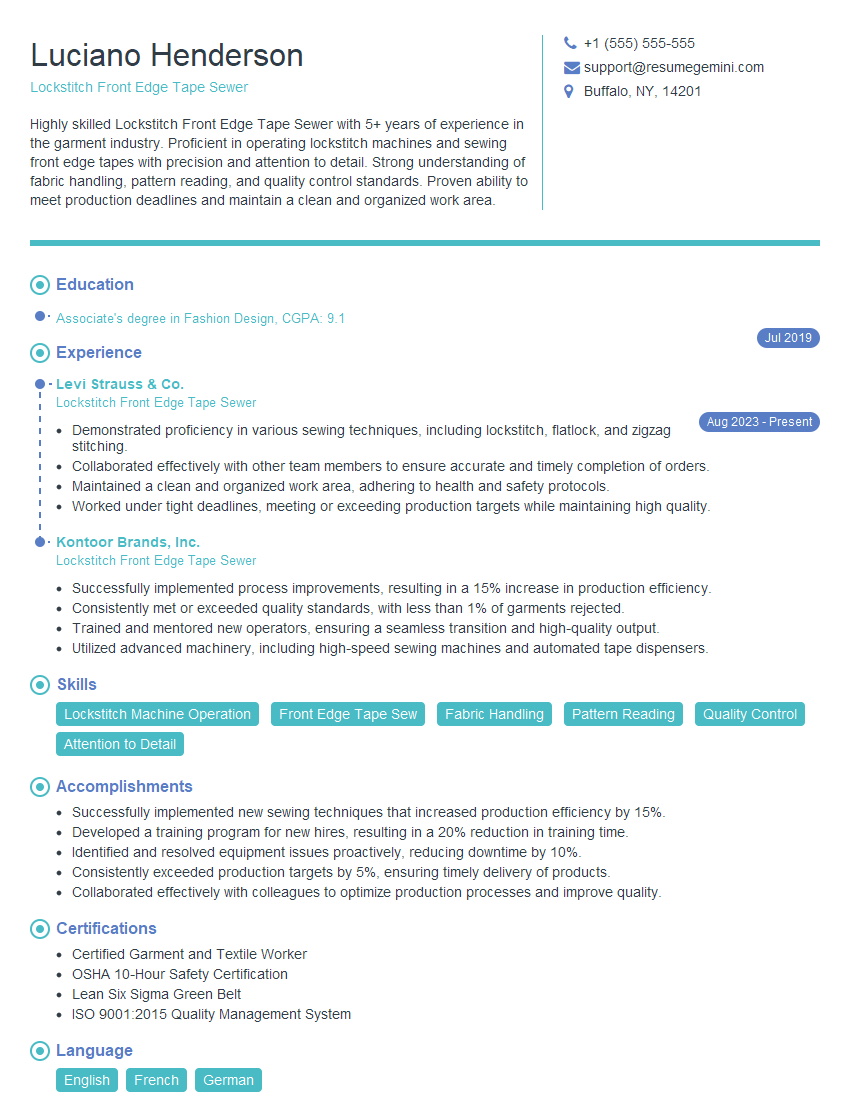

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Lockstitch Front Edge Tape Sewer

1. Describe the key responsibilities of a Lockstitch Front Edge Tape Sewer?

As a Lockstitch Front Edge Tape Sewer, my primary responsibilities would include:

- Operating lockstitch sewing machines to sew front edge tape onto various garments

- Maintaining high levels of accuracy and precision to ensure the tape is sewn securely and evenly

- Inspecting sewn garments for defects and ensuring they meet quality standards

- Making necessary adjustments to the sewing machine to optimize performance

- Adhering to safety protocols and maintaining a clean and organized work area

2. What techniques do you use to achieve consistent and precise sewing results?

Accurate Measurement

- Using measuring tools to ensure the tape is positioned and sewn at the correct distance from the garment’s edge

- Maintaining consistent tension throughout the sewing process to prevent puckering or stretching

Proper Machine Setup

- Selecting the appropriate needle and thread size for the fabric and tape materials

- Adjusting the stitch length and tension to create a secure and durable seam

Skillful Handling

- Guiding the fabric and tape through the machine smoothly and evenly

- Using hand-eye coordination to ensure the tape is sewn on straight and without any deviations

3. How do you handle situations where the fabric or tape is delicate or prone to damage?

When working with delicate fabrics or tape, I employ the following techniques to minimize damage:

- Using a fine needle and thread to prevent excessive perforations

- Adjusting the machine tension to the lowest setting to avoid stretching or tearing

- Handling the fabric and tape with care, avoiding excessive pulling or stretching

- Using a stabilizer or interfacing to provide support and prevent the fabric from shifting or puckering

4. Describe your process for inspecting finished garments for defects.

My inspection process involves the following steps:

- Thoroughly examining the garment for any visible defects, such as misalignment, loose stitching, or frayed edges

- Checking the tape seam for proper adhesion, ensuring it is securely attached to the fabric

- Inspecting the garment for any potential quality issues that may affect its appearance or durability

- Reporting any defects found to the appropriate supervisor or quality control team

5. What factors influence the selection of the needle and thread for a specific sewing task?

The selection of needle and thread is influenced by the following factors:

- Fabric Type: The thickness, texture, and stretchiness of the fabric determine the appropriate needle size and thread weight

- Tape Material: The composition and thickness of the tape influence the needle type and thread strength required

- Seam Type: The desired seam strength and appearance guide the selection of needle shape and thread properties

- Sewing Machine: The capabilities of the sewing machine, such as its stitch length and tension range, also affect the choice of needle and thread

6. How do you ensure the safety and efficiency of your workspace?

I prioritize safety and efficiency in my workspace through the following practices:

- Keeping the work area clean and organized to prevent tripping hazards and clutter

- Maintaining proper posture and using ergonomic tools to minimize strain and discomfort

- Following established safety protocols, such as wearing appropriate safety gear and using machinery correctly

- Regularly checking equipment and reporting any potential hazards or malfunctions

- Participating in safety training and staying updated on industry best practices

7. Describe the importance of maintaining and calibrating sewing machines for optimal performance.

Regular maintenance and calibration of sewing machines are crucial for:

- Accuracy and Precision: Proper calibration ensures consistent stitch length, tension, and alignment, leading to high-quality sewing results

- Efficiency: Well-maintained machines operate smoothly, reducing downtime and increasing productivity

- Durability: Regular maintenance extends the life of sewing machines, minimizing the need for costly repairs or replacements

- Safety: Calibrated machines are less prone to malfunctions or accidents, ensuring a safe work environment

8. How do you troubleshoot common sewing machine problems, such as thread breakage or tension issues?

To troubleshoot common sewing machine problems, I follow a systematic approach:

- Identify the Problem: Observe the machine’s behavior and symptoms to determine the nature of the issue

- Check Threading: Ensure the thread is properly threaded through all guides and tension discs

- Adjust Tension: Adjust the upper and lower thread tension to achieve the desired stitch quality

- Inspect Needles: Check for bent, damaged, or dull needles and replace if necessary

- Clean and Lubricate: Remove any lint, dust, or debris from the machine and lubricate moving parts

9. How do you stay updated on industry trends and best practices in lockstitch front edge tape sewing?

I stay updated on industry trends and best practices through the following methods:

- Attend industry events and workshops: Participate in conferences, seminars, and training sessions to learn about new techniques and technologies

- Read trade publications: Subscribe to industry magazines and journals to stay informed about the latest developments and innovations

- Network with colleagues: Exchange knowledge and ideas with other sewing professionals to gain insights and learn from their experiences

- Online resources: Utilize online forums, websites, and tutorials to access valuable information and connect with industry experts

10. Describe your experience in working within a team environment on a sewing production line.

In previous team environments, I have effectively contributed by:

- Collaborating with teammates: Communicated clearly, assisted others, and shared knowledge to achieve common goals

- Maintaining a positive attitude: Remained enthusiastic and motivated, even during challenging times

- Adapting to changing priorities: Flexibly adjusted to changing production demands and deadlines

- Meeting production targets: Consistently exceeded production quotas while maintaining high quality standards

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Lockstitch Front Edge Tape Sewer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Lockstitch Front Edge Tape Sewer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Lockstitch Front Edge Tape Sewers are responsible for sewing front edge tape onto various types of garments. They ensure that the tape is sewn on securely and evenly, following specific production guidelines. Their key responsibilities include:

1. Sewing Front Edge Tape

The primary task is to sew front edge tape onto garments using a lockstitch sewing machine. They must ensure that the tape is sewn on straight and evenly, without any puckering or loose threads.

- Operate and maintain a lockstitch sewing machine.

- Follow production guidelines and specifications for sewing front edge tape.

- Inspect sewn garments for quality and accuracy.

2. Maintaining Equipment

Sewers are responsible for maintaining their sewing machines and other equipment. This includes cleaning, oiling, and adjusting the machines to ensure they are operating correctly.

- Clean and oil sewing machines and other equipment.

- Adjust and maintain sewing machines for optimal performance.

- Identify and troubleshoot equipment problems.

3. Meeting Production Targets

Sewers are expected to meet production targets for the number of garments they sew each day. They must work efficiently and accurately to ensure that orders are completed on time.

- Meet daily production targets for sewing front edge tape.

- Work efficiently and accurately to minimize errors.

- Prioritize tasks and manage time effectively.

4. Adhering to Safety Regulations

Sewing involves the use of sharp needles and other potentially hazardous equipment. Sewers must follow all safety regulations to prevent accidents and injuries.

- Follow all safety regulations and guidelines.

- Wear appropriate safety gear, such as gloves and safety glasses.

- Maintain a clean and organized work area.

Interview Tips

Preparing for an interview for a Lockstitch Front Edge Tape Sewer position is crucial to showcase your skills and experience. Here are some interview tips and hacks to help you ace the interview:

1. Research the Company

Before the interview, take the time to research the company and the specific role you’re applying for. Understand the company’s culture, values, and products. This knowledge will demonstrate your interest in the position and show that you’ve taken the initiative to learn more about the organization.

- Visit the company’s website and social media pages.

- Read industry news and articles related to the company.

- Connect with current or former employees on LinkedIn.

2. Practice Common Interview Questions

Prepare for common interview questions by practicing your answers beforehand. This will help you feel more confident and articulate during the interview. Prepare for questions such as:

- Tell me about your experience as a Lockstitch Front Edge Tape Sewer.

- What are your strengths and weaknesses as a sewer?

- Why are you interested in this position?

- What are your salary expectations?

3. Highlight Your Skills and Experience

During the interview, emphasize your skills and experience that are relevant to the role. Use specific examples to demonstrate your abilities, such as:

- Describe a time when you successfully sewed front edge tape on a complex garment.

- Explain how you troubleshoot and resolve sewing machine problems.

- Share your strategies for meeting production targets while maintaining quality.

4. Be Enthusiastic and Professional

Throughout the interview, maintain a positive and enthusiastic attitude. Show that you’re passionate about sewing and eager to contribute to the company. Dress professionally and arrive on time for your interview.

- Smile, make eye contact, and speak clearly.

- Ask thoughtful questions about the position and the company.

- Thank the interviewer for their time and consideration.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Lockstitch Front Edge Tape Sewer interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!