Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Overedge Sewer interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Overedge Sewer so you can tailor your answers to impress potential employers.

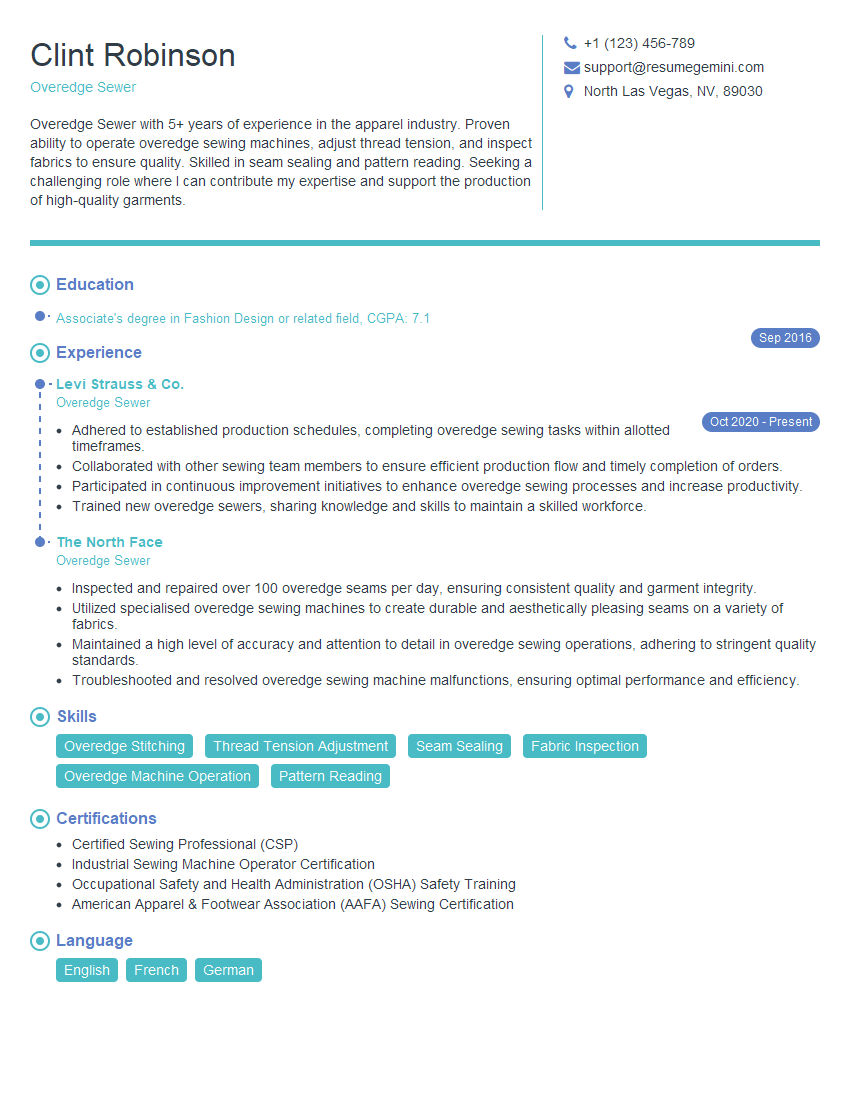

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Overedge Sewer

1. What are the key factors to consider when designing an overedge sewer system?

- The type of fabric being sewn

- The desired seam strength and appearance

- The production speed required

- The available space and budget

2. What are the different types of overedge sewing machines available?

Mechanical overedge sewing machines

- Simple and easy to operate

- Limited stitch patterns and features

Electronic overedge sewing machines

- More advanced features and stitch patterns

- Easier to adjust and control

Computerized overedge sewing machines

- Most advanced and versatile

- Can be programmed to create custom stitches and patterns

3. What are the advantages of using an overedge sewer?

- Produces strong and durable seams

- Can sew a variety of fabrics

- Can be used for both lightweight and heavyweight materials

- Relatively easy to operate and maintain

4. What are the different types of overedge stitches?

- Two-thread overedge stitch

- Three-thread overedge stitch

- Four-thread overedge stitch

- Five-thread overedge stitch

5. How do you troubleshoot common overedge sewing problems?

- Skipped stitches

- Broken threads

- Puckering

- Waving

6. What are the safety precautions that should be taken when operating an overedge sewer?

- Always wear safety glasses

- Keep hands away from moving parts

- Do not operate the machine if it is damaged

- Unplug the machine before performing any maintenance or repairs

7. What are the different types of overedge sewing feet?

- Standard overedge foot

- Narrow overedge foot

- Wide overedge foot

- Blind hemming foot

8. How do you adjust the tension on an overedge sewing machine?

- Locate the tension dials on the machine

- Turn the dials to increase or decrease the tension

- Sew a test seam and adjust the tension as needed

9. How do you thread an overedge sewing machine?

- Follow the threading guide on the machine

- Thread the needles first

- Thread the loopers next

- Pull the threads through the tension discs

10. How do you maintain an overedge sewing machine?

- Clean the machine regularly

- Oil the machine according to the manufacturer’s instructions

- Inspect the machine for worn or damaged parts

- Have the machine serviced by a qualified technician on a regular basis

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Overedge Sewer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Overedge Sewer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

An Overedge Sewer is responsible for operating and maintaining overedge sewing machines used in the manufacturing of garments and other textile products. The key job responsibilities include:

1. Machine Operation

Setting up and operating overedge sewing machines to sew seams and edges of garments and other textile products.

2. Quality Control

Inspecting sewn seams and edges to ensure they meet quality standards and specifications.

3. Maintenance and Repair

Performing routine maintenance and minor repairs on overedge sewing machines to ensure optimal performance.

4. Troubleshooting

Identifying and resolving problems with overedge sewing machines, including thread tension, stitch quality, and machine settings.

5. Fabric Handling

Handling and guiding fabrics through the overedge sewing machine, ensuring proper alignment and tension.

6. Production Monitoring

Monitoring production output and maintaining records of machine performance and production quantities.

7. Safety Compliance

Following safety protocols and operating overedge sewing machines in a safe and responsible manner.

Interview Tips

Preparing thoroughly for an interview can significantly increase your chances of success. Here are some tips to help you ace your interview for an Overedge Sewer position:

1. Research the Company and Position

Research the company you are applying to, including their history, products or services, and company culture. This will help you understand the company’s values and needs, and tailor your answers accordingly.

Review the job description carefully to understand the specific requirements and responsibilities of the Overedge Sewer position. This will help you highlight your relevant skills and experience during the interview.

2. Practice Answering Common Interview Questions

There are several common interview questions that you are likely to encounter, such as “Tell me about yourself,” “Why are you interested in this position?,” and “What are your strengths and weaknesses?”

Prepare concise and well-thought-out answers to these questions that showcase your qualifications and enthusiasm for the role.

3. Highlight Your Skills and Experience

Emphasize your skills and experience that are relevant to the Overedge Sewer position. For example, highlight your experience with operating overedge sewing machines, your ability to maintain and troubleshoot machines, and your attention to detail.

Quantify your accomplishments whenever possible. For instance, instead of saying “I operated overedge sewing machines,” you could say “I operated overedge sewing machines to produce an average of 100 garments per hour, meeting or exceeding production targets.”

4. Demonstrate Your Passion and Enthusiasm

Convey your passion for sewing and your interest in the Overedge Sewer position. Explain why you are excited about the opportunity to contribute your skills to the company.

Your enthusiasm and passion can set you apart from other candidates and make a lasting impression on the interviewer.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Overedge Sewer interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.