Are you gearing up for a career in Overedger? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Overedger and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

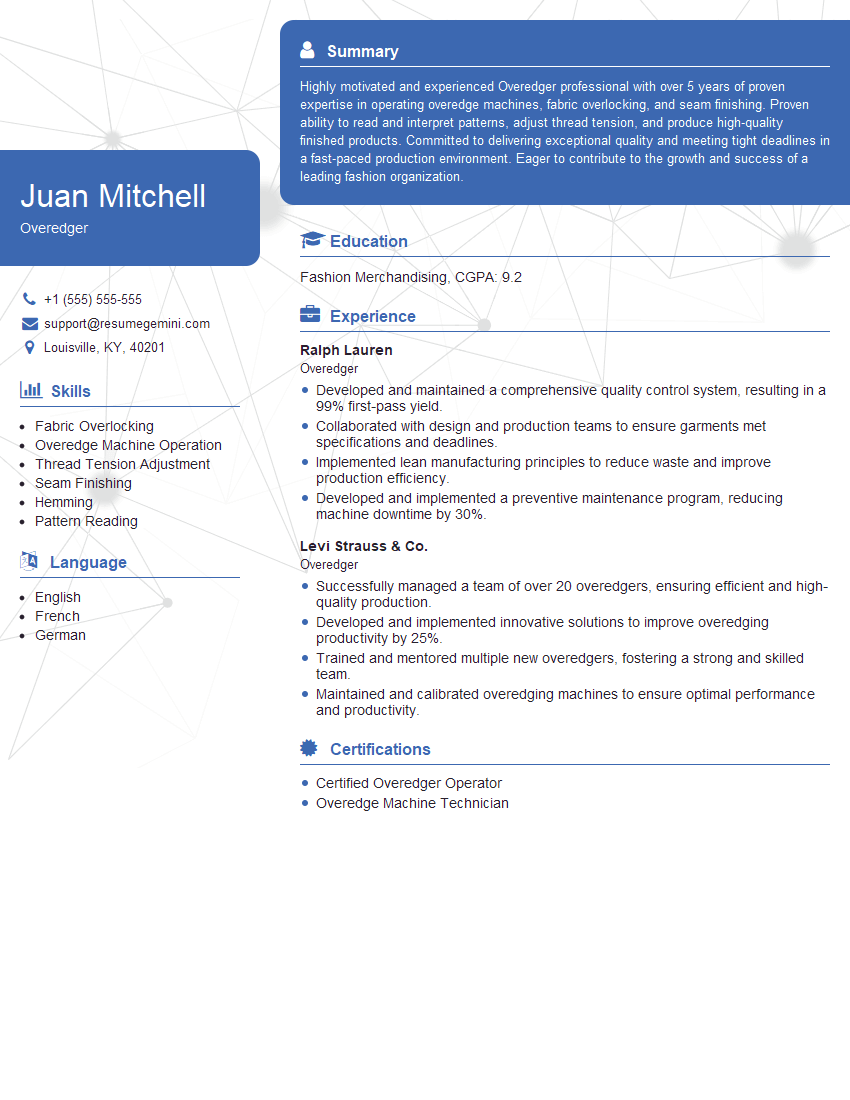

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Overedger

1. What are the different types of overedging machines and their uses?

- Flatbed overedgers: These machines are used for sewing flat fabrics, such as garments, curtains, and tablecloths.

- Cylinder-bed overedgers: These machines are used for sewing tubular fabrics, such as sleeves, pant legs, and waistbands.

- Combination overedgers: These machines can sew both flat and tubular fabrics, making them a versatile option for a variety of sewing projects.

2. What are the key features to look for when choosing an overedging machine?

Speed

- The speed of an overedging machine is measured in stitches per minute (SPM). Higher SPM means the machine can sew faster, increasing productivity.

- Consider the types of projects you will be working on and choose a machine with an appropriate SPM.

Stitch quality

- The stitch quality of an overedging machine is determined by the type of stitch it produces, the tension of the threads, and the condition of the needles.

- Look for a machine that produces a consistent, durable stitch with minimal puckering.

Ease of use

- An overedging machine should be easy to thread, adjust, and maintain.

- Consider your skill level and choose a machine that is user-friendly and suitable for your needs.

3. How do you maintain an overedging machine to ensure optimal performance?

- Regular cleaning: Clean the machine regularly to remove lint, dust, and fabric scraps. Use a soft brush or compressed air to clean the exterior and interior of the machine.

- Lubrication: Lubricate the machine according to the manufacturer’s instructions. Use a high-quality lubricant specifically designed for overedging machines.

- Needle replacement: Replace the needles regularly to ensure optimal stitch quality. Dull or damaged needles can cause skipped stitches and fabric damage.

4. What are the common problems that can occur with overedging machines and how can they be resolved?

Skipped stitches

- Cause: Dull or damaged needles, incorrect thread tension, or fabric too thick for the machine.

- Solution: Replace the needles, adjust the thread tension, or use a lighter fabric.

Puckering

- Cause: Incorrect thread tension or the presser foot is not properly adjusted.

- Solution: Adjust the thread tension or the presser foot height.

Thread breakage

- Cause: Incorrect thread tension, damaged needles, or burrs on the thread path.

- Solution: Adjust the thread tension, replace the needles, or remove the burrs.

5. How do you troubleshoot and resolve tension problems on an overedging machine?

- Check the thread tension dials: Ensure that the thread tension dials are set to the correct tension for the type of thread and fabric being used.

- Inspect the thread path: Check the thread path for any obstructions or damage that could be causing the thread to become tangled or broken.

- Rethread the machine: Sometimes, rethreading the machine can resolve tension problems.

6. What are the different types of threads that can be used in an overedging machine and their recommended applications?

Cotton thread

- Natural fiber, strong and durable.

- Suitable for a wide range of fabrics, including cotton, linen, and denim.

Polyester thread

- Synthetic fiber, resistant to fading and abrasion.

- Suitable for synthetic fabrics and fabrics intended for outdoor use.

Silk thread

- Natural fiber, luxurious sheen.

- Suitable for delicate fabrics, such as silk and chiffon.

7. How do you adjust the stitch length and width on an overedging machine?

- Stitch length: Adjust the stitch length by turning the stitch length dial. Shorter stitches produce a more durable seam, while longer stitches are more elastic.

- Stitch width: Adjust the stitch width by turning the stitch width dial. Narrower stitches are suitable for lightweight fabrics, while wider stitches are suitable for heavier fabrics.

8. What safety precautions should be taken when operating an overedging machine?

- Keep hands away from the needle: Always keep your hands away from the needle while the machine is running.

- Use safety glasses: Wear safety glasses to protect your eyes from flying debris.

- Unplug the machine when not in use: Always unplug the machine when you are not using it or when performing maintenance.

9. What are the different types of seams that can be sewn on an overedging machine?

Overlock seam

- A basic seam that trims, overcasts, and joins two pieces of fabric.

- Suitable for a wide range of fabrics.

Flatlock seam

- A decorative seam that creates a flat, durable finish.

- Suitable for heavier fabrics, such as denim and canvas.

Rolled hem

- A narrow, rolled hem that is both decorative and functional.

- Suitable for lightweight fabrics, such as silk and chiffon.

10. What are the key differences between a serger and an overedging machine?

- Overedging machines are designed specifically for finishing the edges of fabrics. They use multiple threads to create a durable, professional-looking finish.

- Sergers are more versatile machines that can be used for both finishing edges and sewing seams. They typically use fewer threads than overedging machines.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Overedger.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Overedger‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

An Overedger is responsible for operating an overedging machine to finish the edges of fabric pieces in the production of garments, textiles, and other products.

1. Operating and Maintaining Equipment

Overedgers operate and maintain overedging machines, ensuring they are in good working order.

- Thread machines and adjust tension to achieve desired stitch quality.

- Inspect machines regularly to identify and resolve any mechanical issues.

2. Quality Control

Overedgers monitor the quality of the overedging process.

- Check the stitch quality, tension, and alignment to ensure compliance with specifications.

- Identify and correct defects in the overedging process.

3. Production Efficiency

Overedgers strive to maintain high levels of production efficiency.

- Feed fabric into machines at an optimal pace to maximize output.

- Minimize machine downtime by promptly resolving any issues.

4. Collaboration and Communication

Overedgers collaborate with other team members and communicate with supervisors.

- Work closely with sewing operators to ensure that fabric pieces are properly prepared for overedging.

- Report any production issues or quality concerns to supervisors.

Interview Tips

Preparing for an overedger interview requires careful research and practice. Here are some tips to help you ace the interview:

1. Research the Company and Role

Familiarize yourself with the company’s history, products, and culture. Understand the specific requirements of the overedger role and how it aligns with your skills.

- Visit the company website and social media pages.

- Review the job description thoroughly.

2. Highlight Relevant Skills and Experience

Emphasize your proficiency in operating overedging machines and your attention to detail. Quantify your accomplishments whenever possible.

- Discuss your experience with different types of fabrics and thread.

- Provide examples of your ability to maintain high production standards and meet quality specifications.

3. Demonstrate Your Problem-Solving Abilities

Overedgers often encounter technical issues. Prepare to discuss your problem-solving approach and provide examples of how you have successfully resolved machine malfunctions.

- Describe a situation where you identified and fixed a machine issue.

- Explain how you prioritize tasks and manage your time effectively.

4. Prepare for Common Interview Questions

Practice answering common interview questions related to overedging, such as:

- Tell me about your experience operating overedging machines.

- How do you ensure the quality of your overedging work?

- Describe a challenging situation you faced as an overedger and how you overcame it.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Overedger interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!