Feeling lost in a sea of interview questions? Landed that dream interview for Overlock Operator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Overlock Operator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

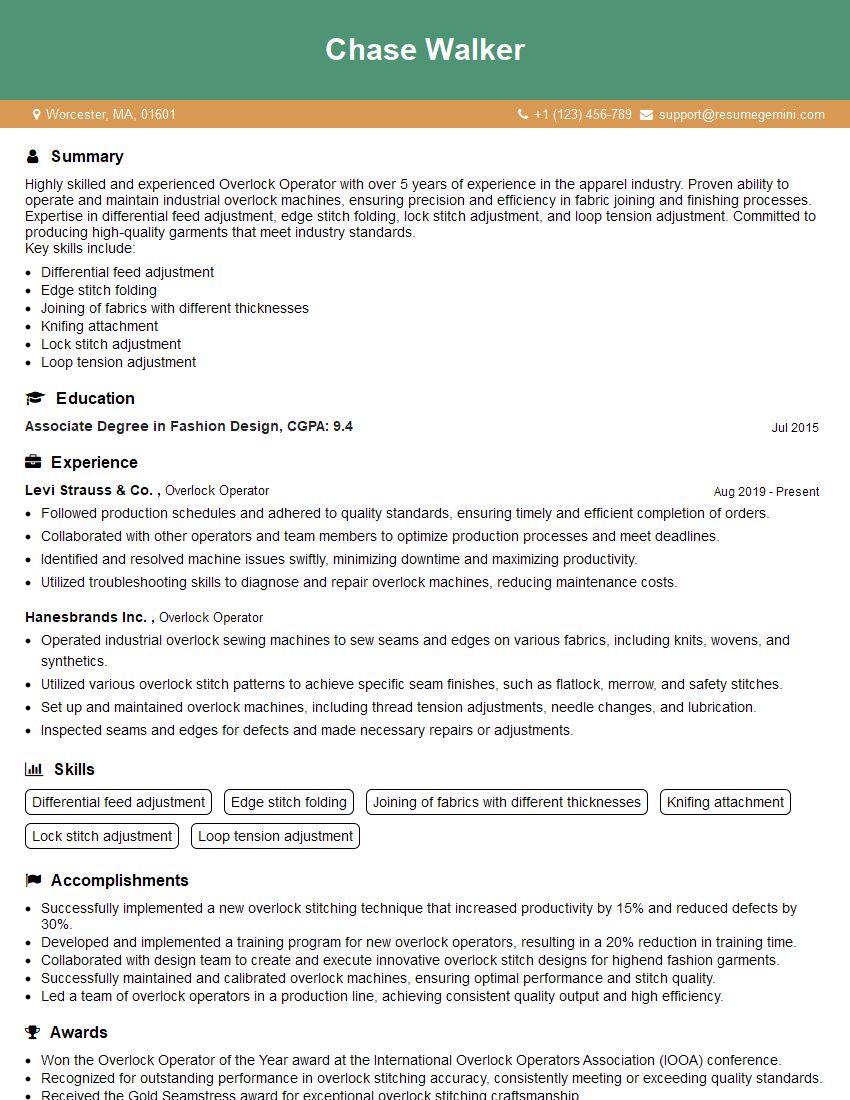

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Overlock Operator

1. What are the different types of overlock machines you have operated?

I have operated both 3-thread and 5-thread overlock machines. I am familiar with the different types of stitches that can be produced on each machine, and I can adjust the machine settings to produce the desired stitch quality.

2. What are the most common problems you encounter when operating an overlock machine? How do you troubleshoot and resolve these problems?

Troubleshooting

- If the machine is not sewing properly, I first check the thread tension. If the tension is too loose, the stitches will be weak and may break. If the tension is too tight, the stitches will be too tight and may pucker the fabric.

- I also check the needle. If the needle is bent or damaged, it can cause the machine to skip stitches or produce uneven stitches.

Resolution

- To resolve these problems, I adjust the thread tension and replace the needle as needed.

3. What are the safety precautions that you must take when operating an overlock machine?

When operating an overlock machine, I always wear safety glasses to protect my eyes from flying debris. I also keep my hands away from the moving parts of the machine, and I never reach into the machine while it is running.

4. What is the difference between a serger and an overlock machine?

A serger is a type of overlock machine that is used to finish the edges of fabric. Sergers use a series of needles and loopers to create a chain stitch that is both strong and stretchy. Overlock machines, on the other hand, use a single needle and looper to create a stitch that is more decorative than functional.

5. What are the different types of fabrics that can be sewn on an overlock machine?

Overlock machines can be used to sew a variety of fabrics, including cotton, polyester, silk, and wool. However, some fabrics, such as knits and delicate fabrics, require special care when sewing on an overlock machine.

6. What is the best way to maintain an overlock machine?

To maintain an overlock machine, I regularly clean and oil the machine. I also check the needles and loopers for wear and tear, and I replace them as needed.

7. What are the different types of stitches that can be produced on an overlock machine?

Overlock machines can produce a variety of stitches, including the 3-thread overlock stitch, the 4-thread overlock stitch, and the 5-thread safety stitch. Each stitch has its own unique purpose and is used for different types of fabrics and applications.

8. What is the difference between a rolled hem and a flatlocked seam?

A rolled hem is a type of overlock stitch that creates a narrow, rolled edge on the fabric. A flatlocked seam is a type of overlock stitch that creates a flat, durable seam that is often used on sportswear and other garments that require a strong seam.

9. What are the different types of thread that can be used on an overlock machine?

Overlock machines can use a variety of threads, including cotton, polyester, and nylon. The type of thread that is used depends on the fabric that is being sewn and the desired stitch quality.

10. What is the best way to learn how to operate an overlock machine?

The best way to learn how to operate an overlock machine is to take a class or workshop. There are also many online resources that can provide you with information on how to use an overlock machine.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Overlock Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Overlock Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Overlock Operators are responsible for operating overlock machines to sew seams on garments or other fabric products. They must be able to operate the machine efficiently and accurately, and to troubleshoot any problems that may arise.

1. Operating the Overlock Machine

Overlock Operators must be able to operate the overlock machine safely and efficiently. They must be able to adjust the machine settings to achieve the desired seam quality, and to troubleshoot any problems that may arise.

- Threading the machine with the correct thread

- Adjusting the stitch length and tension

- Guiding the fabric through the machine

2. Inspecting the Seams

Overlock Operators must inspect the seams they have sewn to ensure that they are of good quality. They must be able to identify any defects, such as skipped stitches or uneven seams, and to correct them.

- Checking the seam for skipped stitches or uneven stitching

- Inspecting the seam for any puckering or gathering

- Measuring the seam to ensure that it is the correct length

3. Maintaining the Machine

Overlock Operators must maintain the overlock machine to ensure that it is in good working condition. They must be able to clean and oil the machine, and to replace any worn or damaged parts.

- Cleaning the machine with a brush or compressed air

- Oiling the machine according to the manufacturer’s instructions

- Replacing any worn or damaged parts

4. Other Duties

In addition to the above responsibilities, Overlock Operators may also be required to perform other duties, such as:

- Loading and unloading fabric from the machine

- Assisting other operators with their work

- Maintaining a clean and organized work area

Interview Tips

To ace the interview for an Overlock Operator position, it is important to be prepared. Here are some tips:

1. Research the Company

Before you go to the interview, take some time to research the company. This will help you to understand the company’s culture and values, and to tailor your answers to the interviewer’s questions.

- Visit the company’s website

- Read the company’s mission statement and values

- Look at the company’s products or services

2. Practice Your Answers

Once you have researched the company, it is important to practice your answers to common interview questions. This will help you to feel confident and prepared when you go to the interview.

- Write down some of the most common interview questions

- Practice answering the questions out loud

- Get feedback from a friend or family member

3. Be Prepared to Talk About Your Experience

The interviewer will want to know about your experience as an Overlock Operator. Be prepared to talk about your skills and experience, and to provide examples of your work.

- Highlight your skills and experience in operating an overlock machine

- Provide examples of your work, such as garments or other fabric products that you have sewn

- Be prepared to talk about your experience in maintaining overlock machines

4. Ask Questions

At the end of the interview, be sure to ask the interviewer some questions. This will show that you are interested in the position and that you are taking the interview seriously.

- Ask about the company’s culture and values

- Ask about the company’s training and development opportunities

- Ask about the company’s growth plans

Next Step:

Now that you’re armed with the knowledge of Overlock Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Overlock Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini