Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Piped Pocket Machine Operator interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Piped Pocket Machine Operator so you can tailor your answers to impress potential employers.

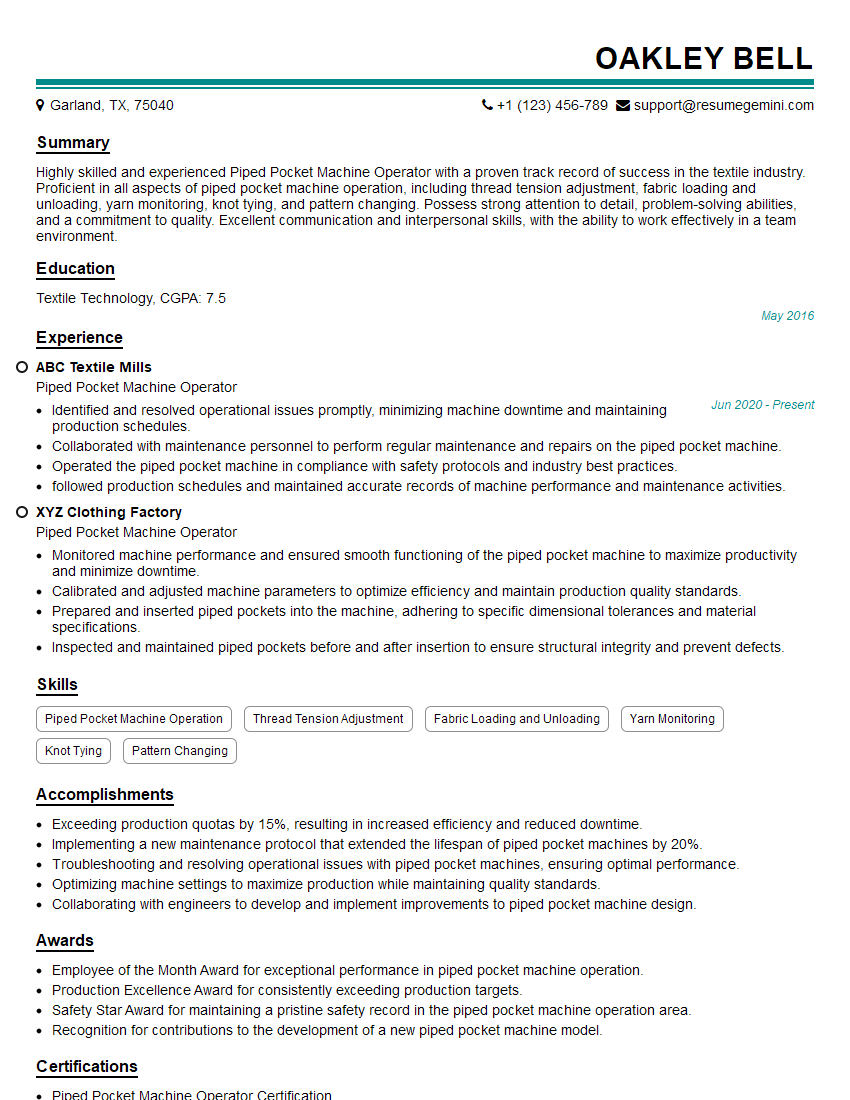

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Piped Pocket Machine Operator

1. What are the key responsibilities of a Piped Pocket Machine Operator?

- Operate and maintain piped pocket machines to produce pockets for use in various products.

- Set up and adjust machines, load materials, and monitor operations to ensure efficiency and quality.

- Inspect finished products and make adjustments as necessary to meet specifications.

- Maintain a clean and organized work area, and follow safety protocols.

- Troubleshoot and resolve operational issues, and perform routine maintenance and repairs.

2. Describe the different types of piped pockets and their applications.

of the answer: Piping materials

- Fabric Piping: Used for garments, bags, and home décor items.

- Metal Piping: Used for industrial applications, such as hoses and tubing.

- Plastic Piping: Used for plumbing, irrigation, and electrical conduits.

Subheading of the answer: Pocket styles

- Welt Pockets: Flat pockets with a stitched edge.

- Patch Pockets: Pockets sewn onto the outside of a garment or fabric.

- Piped Pockets: Pockets with a piping detail around the edges.

- Hidden Pockets: Pockets concealed within the fabric.

3. Explain the process of setting up and operating a piped pocket machine.

- Install the correct piping foot and adjust the tension settings.

- Load the fabric and piping material onto the machine.

- Set the stitch length and width according to the desired pocket size.

- Start the machine and guide the fabric through the piping foot.

- Monitor the operation and make adjustments as needed to ensure proper stitching.

4. How do you ensure the quality of the finished product?

- Inspecting the fabric for defects before loading it into the machine.

- Checking the piping material for size and quality.

- Monitoring the stitching process to ensure proper tension and stitch formation.

- Measuring the finished pockets to ensure they meet the required specifications.

- Performing regular maintenance and calibration of the machine to prevent errors.

5. Describe the safety precautions that must be observed when operating a piped pocket machine.

- Wearing appropriate safety gear, such as gloves and safety glasses.

- Keeping the work area clean and free of obstructions.

- Ensuring that the machine is properly grounded and that all electrical connections are secure.

- Never reaching into the machine while it is running.

- Following all manufacturer’s instructions and safety guidelines.

6. What are the common problems that occur while operating a piped pocket machine, and how do you troubleshoot them?

- Broken or damaged piping: Replace the piping and check for any obstructions in the machine.

- Uneven stitching: Adjust the tension settings or check for any issues with the piping foot.

- Fabric puckering: Adjust the stitch length or use a different type of fabric.

- Pockets not attaching properly: Check the alignment of the fabric and piping, and ensure that the machine is properly calibrated.

- Machine overheating: Stop the machine and allow it to cool down. Check for any blockages or lubrication issues.

7. How do you maintain and clean a piped pocket machine?

- Regularly cleaning the machine with a soft brush or compressed air.

- Oiling and lubricating moving parts according to the manufacturer’s instructions.

- Checking and tightening screws and bolts.

- Inspecting the electrical components and wiring for any damage or loose connections.

- Storing the machine in a clean and dry environment when not in use.

8. What are your strengths and weaknesses as a Piped Pocket Machine Operator?

Subheading of the answer: Strengths

- Proficient in operating and maintaining piped pocket machines.

- Excellent attention to detail and ability to produce high-quality products.

- Strong troubleshooting skills and ability to resolve operational issues efficiently.

- Experience in working in a fast-paced and demanding production environment.

- Committed to safety and following all established protocols.

Subheading of the answer: Weakness

- Limited experience with newer models of piped pocket machines.

- Not familiar with all types of fabrics and their suitability for piping.

9. Why are you interested in this Piped Pocket Machine Operator position?

- I am eager to contribute my skills and experience to your company.

- I am particularly interested in the opportunity to work with the latest piped pocket machines.

- I believe that my attention to detail and commitment to quality would make me a valuable asset to your team.

- I am confident that I can quickly learn and adapt to the specific requirements of this position.

- I am excited about the prospect of working in a dynamic and challenging work environment.

10. Do you have any questions for me about the position or the company?

- What is the expected production output for this position?

- What opportunities are there for professional development and growth within the company?

- Can you provide more information about the company’s commitment to sustainability?

- What is the company culture like, and how do you foster a positive work environment?

- Are there any specific training programs or certifications that would be beneficial for this role?

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Piped Pocket Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Piped Pocket Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Piped Pocket Machine Operators are responsible for operating and maintaining piped pocket machines, which are used to produce piped pockets in garments. Key job responsibilities include:

1. Machine Operation

Operating piped pocket machines to produce piped pockets of various sizes and shapes.

- Setting up and adjusting the machine according to job specifications.

- Loading fabric and other materials into the machine.

- Monitoring the machine during operation and making necessary adjustments.

2. Quality Control

Inspecting piped pockets for quality and accuracy.

- Identifying and correcting defects in piped pockets.

- Maintaining records of quality control checks.

3. Machine Maintenance

Performing routine maintenance and repairs on piped pocket machines.

- Cleaning and lubricating the machine.

- Replacing worn or damaged parts.

- Troubleshooting and resolving machine problems.

4. Safety

Following safety procedures and regulations when operating piped pocket machines.

- Wearing appropriate safety gear.

- Keeping the work area clean and organized.

- Reporting any safety hazards or concerns.

Interview Tips

Preparing thoroughly for an interview can give you a significant advantage. Here are some tips to help you ace your interview for a Piped Pocket Machine Operator position:

1. Research the Company and Position

Take the time to research the company you’re applying to, including its history, products or services, and culture. This will demonstrate your interest and enthusiasm for the position.

- Visit the company’s website, read industry news, and check social media for insights.

- Identify the specific skills and experience required for the role and tailor your resume and cover letter accordingly.

2. Practice Your Answers to Common Interview Questions

Anticipate common interview questions and prepare thoughtful answers that highlight your relevant skills and experience. Consider using the STAR method to structure your responses:

- Situation: Briefly describe a relevant situation or experience.

- Task: Explain the specific task or challenge you faced.

- Action: Describe the actions you took to address the situation.

- Result: State the positive outcome or impact of your actions.

3. Be Prepared to Discuss Your Technical Skills

Emphasize your proficiency in operating piped pocket machines. Highlight your ability to set up, adjust, and troubleshoot the machine efficiently.

- Provide specific examples of your experience in producing high-quality piped pockets.

- Demonstrate your understanding of machine maintenance procedures and safety protocols.

4. Showcase Your Problem-Solving Abilities

Interviewers often ask questions to assess your problem-solving skills. Prepare examples of times when you encountered challenges while operating piped pocket machines and describe how you resolved them.

- Explain your logical thought process and the steps you took to troubleshoot and fix the issue.

- Emphasize your ability to work independently and as part of a team to resolve production problems.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Piped Pocket Machine Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.