Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Profile Stitching Machine Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

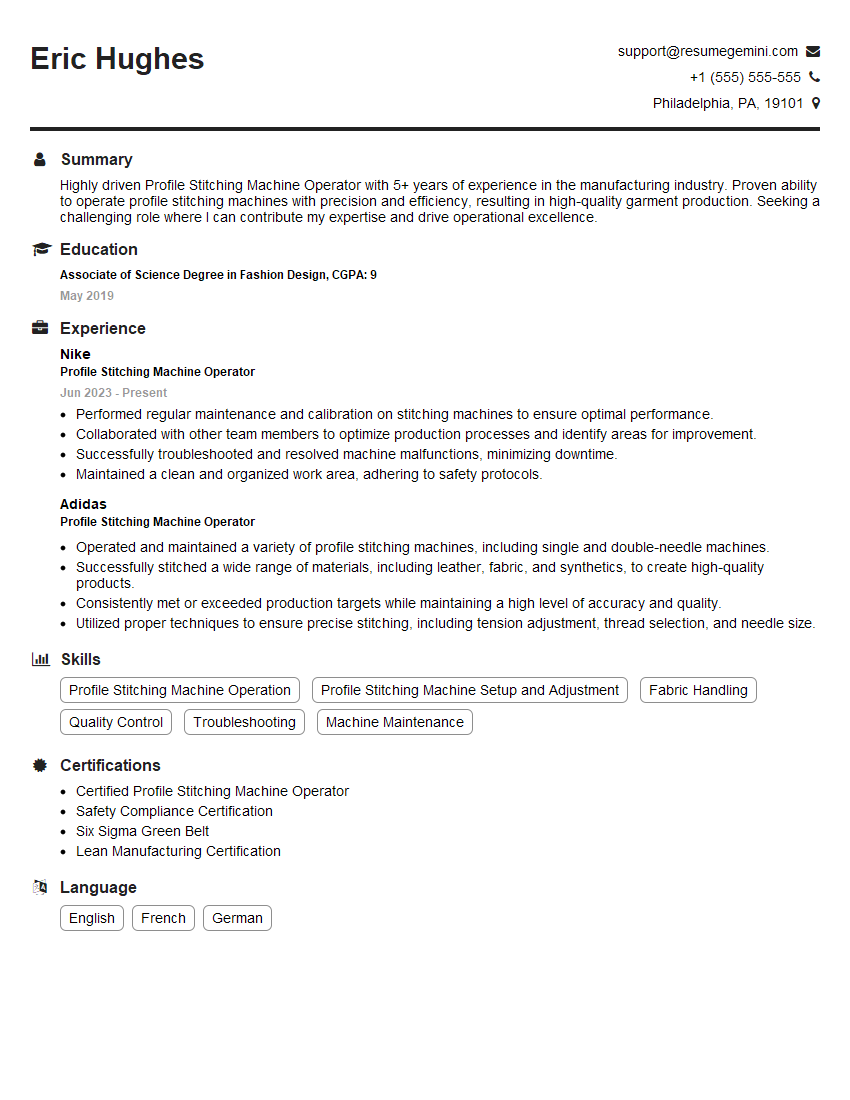

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Profile Stitching Machine Operator

1. What are the different types of profile stitching machines?

There are three main types of profile stitching machines:

- Flatbed profile stitching machines

- Cylinder bed profile stitching machines

- Post-bed profile stitching machines

2. What are the key features of a profile stitching machine?

Stitching Head

- Needle bar stroke: The distance the needle moves up and down.

- Stitch length: The distance between two consecutive stitches.

- Stitch type: The type of stitch used, such as straight stitch, zigzag stitch, or blind stitch.

Machine Bed

- Table size: The surface area of the machine bed.

- Throat size: The distance between the needle and the machine bed.

Feed System

- Types: Walking foot, puller foot, compound feed.

- Purpose: Move the fabric accurately and evenly during stitching.

3. What are the different materials that can be stitched on a profile stitching machine?

Profile stitching machines can stitch a wide variety of materials, including:

- Leather

- Fabric

- Plastic

- Rubber

- Foam

4. What are the different applications of a profile stitching machine?

Profile stitching machines are used in a variety of applications, including:

- Upholstery

- Automotive interiors

- Marine upholstery

- Footwear

- Bags and accessories

5. What are the safety precautions that must be taken when operating a profile stitching machine?

- Always wear safety glasses, gloves, and appropriate clothing.

- Keep hands away from the needle and moving parts.

- Do not operate the machine if it is damaged or malfunctioning.

- Unplug the machine before performing any maintenance or repairs.

- Follow all manufacturer’s instructions for safe operation.

6. How do you troubleshoot common problems with a profile stitching machine?

Some common problems with profile stitching machines include:

- Skipped stitches

- Broken needles

- Fabric puckering

- Uneven stitching

To troubleshoot these problems, you should:

- Check the needle

- Check the thread tension

- Check the feed system

- Check the machine for any damage or malfunction

7. What is the difference between a profile stitching machine and a regular sewing machine?

- Profile stitching machines are designed to sew on curved and irregular surfaces, while regular sewing machines are designed to sew on flat surfaces.

- Profile stitching machines have a longer arm and a larger throat than regular sewing machines, which allows them to sew on larger and more complex projects.

- Profile stitching machines have a wider variety of stitch patterns than regular sewing machines, which allows them to create more decorative and intricate designs.

8. What are the advantages of using a profile stitching machine?

- Profile stitching machines can sew on curved and irregular surfaces, which makes them ideal for a variety of projects.

- Profile stitching machines have a long arm and a large throat, which allows them to sew on larger and more complex projects.

- Profile stitching machines have a wide variety of stitch patterns, which allows them to create more decorative and intricate designs.

9. What are the disadvantages of using a profile stitching machine?

- Profile stitching machines are more expensive than regular sewing machines.

- Profile stitching machines are more difficult to learn how to use than regular sewing machines.

- Profile stitching machines require more maintenance than regular sewing machines.

10. What is your experience with profile stitching machines?

I have been working with profile stitching machines for the past 5 years. I have used them to sew a variety of projects, including upholstery, automotive interiors, and marine upholstery. I am proficient in all aspects of profile stitching machine operation, including machine setup, fabric handling, and troubleshooting.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Profile Stitching Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Profile Stitching Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Profile Stitching Machine Operators play a vital role in the production process, ensuring the high quality and efficiency of the final product. Their key responsibilities include:

1. Operating Profile Stitching Machine

Operate and maintain profile stitching machines to produce high-quality products.

- Set up and adjust machines according to specifications.

- Monitor machine performance and make necessary adjustments.

2. Product Inspection and Quality Control

Inspect stitched products to ensure they meet quality standards.

- Check for defects, such as skipped stitches or misalignment.

- Identify and rectify any issues promptly.

3. Material Handling and Loading

Handle and load materials, such as fabric or leather, into the stitching machine.

- Ensure materials are properly loaded and aligned.

- Minimize material waste and maintain efficient production.

4. Cleaning and Maintenance

Clean and maintain the stitching machine and work area.

- Remove excess thread, dust, and debris regularly.

- Lubricate and inspect machine parts to prevent breakdowns.

Interview Tips

Preparing well for an interview can significantly increase your chances of success. Here are some tips to help you ace your interview for a Profile Stitching Machine Operator position:

1. Research the Company and Role

Thoroughly research the company and the specific role you are applying for. This will help you understand their business, culture, and the responsibilities of the position.

- Visit the company’s website and social media pages.

- Read industry news and articles to stay informed about the latest trends.

2. Practice Your Answers

Prepare for common interview questions by practicing your answers in advance. This will help you articulate your skills, experience, and qualifications effectively.

- Consider using the STAR method (Situation, Task, Action, Result) to structure your answers.

- Seek feedback from a friend, family member, or career counselor on your answers.

3. Prepare Questions for the Interviewer

Asking thoughtful questions at the end of the interview shows your interest and engagement. Prepare a few questions that align with your research on the company and role.

- Inquire about the company’s growth plans or sustainability initiatives.

- Ask about the training and development opportunities available to employees.

4. Dress Professionally and Be Punctual

First impressions matter, so dress professionally for the interview. Arrive on time to demonstrate your punctuality and respect for the interviewer’s time.

- Consider wearing business attire or smart casual clothing.

- Plan your route and allow extra time for unexpected delays.

5. Follow Up After the Interview

After the interview, send a brief thank-you note to the interviewer within 24 hours. Express your appreciation for their time and reiterate your interest in the position.

- Proofread your note carefully for any errors.

- Use the opportunity to highlight any additional skills or experiences that may have come up during the interview.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Profile Stitching Machine Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.