Are you gearing up for an interview for a Sleeve Facing Sewer position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Sleeve Facing Sewer and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

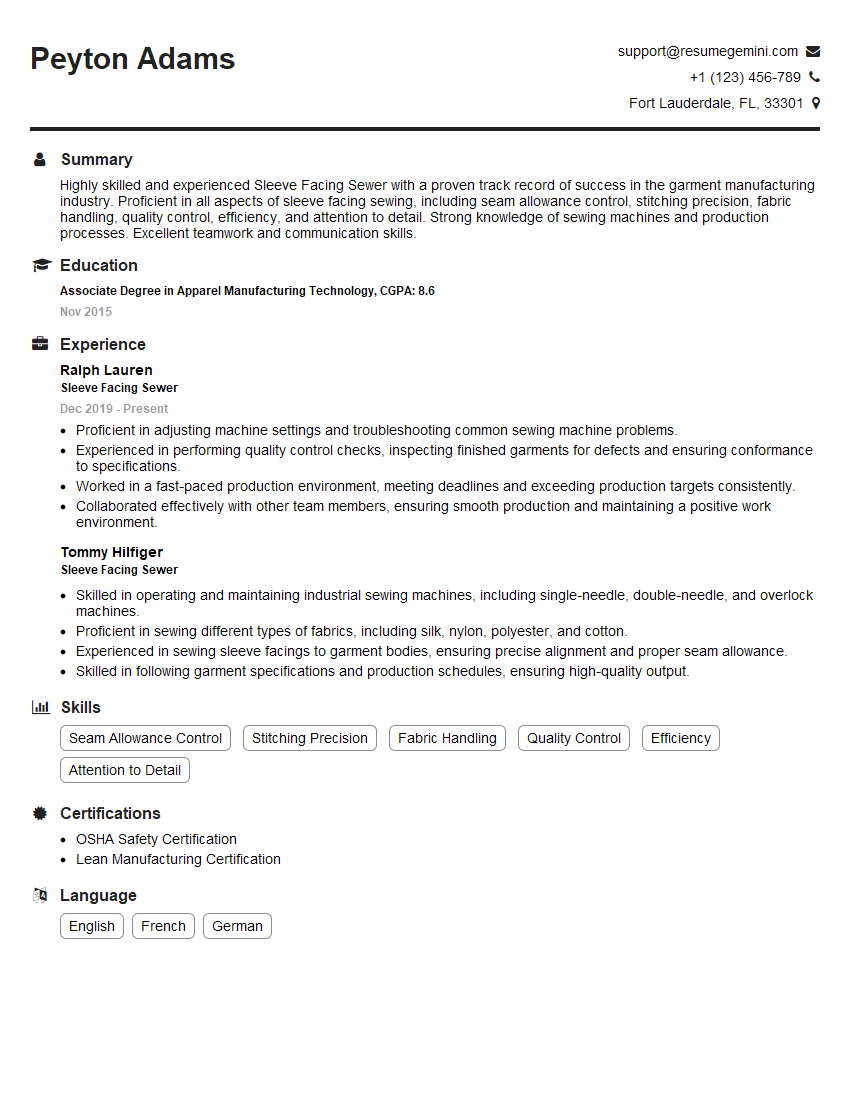

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Sleeve Facing Sewer

1. Explain the responsibilities of a Sleeve Facing Sewer?

As a Sleeve Facing Sewer, my primary responsibilities would include:

- Installing and repairing sleeve facing pipes, including PVC, CPVC, and HDPE pipes

- Using specialized tools and equipment, such as fusion machines and pipe benders

- Testing and inspecting pipelines to ensure proper flow and prevent leaks

- Maintaining and cleaning pipe systems to prevent blockages and ensure efficient operation

- Adhering to safety regulations and industry standards

2. What are the different types of sleeve facing methods, and when would you use each method?

Sleeve Facing Methods

- Slip Lining: A new pipe is inserted into the existing damaged pipe and secured with epoxy

- Cured-in-Place Pipe: A liquid resin is inserted into the damaged pipe and then cured by heat or UV light, creating a new pipe inside the old one

- Expanded Polystyrene (EPS) Sleeves: Pre-molded EPS sleeves are inserted and expanded inside the damaged pipe, creating a new structural layer

Method Selection

- Slip Lining: Used for larger diameter pipes with significant damage requiring a structural solution

- Cured-in-Place Pipe: Suitable for long runs of pipes with minor to moderate damage

- EPS Sleeves: Ideal for small-diameter pipes with localized damage, offering a cost-effective solution

3. How do you determine the size and type of sleeve facing material to use?

I consider several factors when determining the size and type of sleeve facing material:

- Pipe Diameter: The material should snugly fit the inside diameter of the damaged pipe

- Pipe Material: The material must be compatible with the material of the existing pipe

- Damage Severity: The material’s thickness and strength should correspond to the extent of damage

- Installation Method: The material’s flexibility and curing process should align with the chosen method

- Cost and Availability: I consider the budget and timeline, selecting materials that meet requirements while optimizing costs

4. What steps do you take to prepare the damaged pipe for sleeve facing?

Thorough preparation is crucial before sleeve facing:

- Inspection: Assess the pipe’s condition, identify damage, and determine the appropriate repair method

- Cleaning: Remove dirt, debris, and grease from the damaged area using brushes, scrapers, and solvents

- Surface Preparation: Smooth any rough edges, bevel the ends of the damaged pipe, and remove any protrusions or obstructions

- Pipe Alignment: Ensure the pipe is straight and properly aligned before inserting the sleeve facing material

5. How do you ensure that the sleeve facing material is properly installed and adheres to the damaged pipe?

Proper installation is essential for the longevity of the repair:

- Material Compatibility: Verify that the sleeve facing material is compatible with the pipe

- Clean and Dry Surfaces: Ensure the pipe and sleeve surfaces are clean and dry to promote adhesion

- Resin Application: If using epoxy-based materials, apply the resin evenly to the pipe and sleeve surfaces

- Inserting the Sleeve: Carefully insert the sleeve facing material into the damaged pipe, ensuring proper alignment

- Curing or Bonding: Allow the material to cure or bond thoroughly according to the manufacturer’s instructions

- Testing and Inspection: Perform pressure tests and visual inspections to verify the integrity of the repair

6. What are some common challenges you have faced during sleeve facing projects and how did you overcome them?

Sleeve facing can present various challenges:

- Pipe Accessibility: Tight spaces or buried pipes can make installation difficult. I use flexible materials and specialized tools to address these issues.

- Damaged Pipe Condition: Severe damage or complex pipe configurations require innovative solutions. I consult with engineers and manufacturers to determine the best approach.

- Material Compatibility: Ensuring the sleeve material is compatible with the existing pipe is crucial. I conduct thorough research and testing to select the most suitable materials.

- Time Constraints: I prioritize efficient work methods and coordinate with other trades to minimize downtime.

- Safety Concerns: Confined spaces and hazardous materials require strict adherence to safety protocols. I conduct risk assessments and provide thorough safety training.

7. How do you stay up-to-date with the latest advancements in sleeve facing techniques and materials?

I invest in continuous learning to stay abreast of industry developments:

- Attend Industry Conferences and Webinars: Engage with experts and vendors at industry events

- Study Technical Articles and White Papers: Review publications and research findings on sleeve facing

- Join Professional Organizations: Network with other professionals and access resources on industry trends

- Explore Manufacturer Websites and Product Updates: Stay informed about new products and technologies

- Participate in Training and Certification Programs: Enhance skills and knowledge through formal training

8. How do you handle working in confined spaces, and what safety measures do you prioritize?

Working in confined spaces requires proper training and safety measures:

- Proper Ventilation: Ensure adequate ventilation to prevent oxygen deficiency and hazardous fume buildup

- Fall Protection: Utilize harnesses and lifelines to prevent falls

- Lighting: Provide sufficient lighting to enhance visibility and reduce the risk of accidents

- Communication: Establish clear communication protocols for emergencies and regular check-ins

- Hazard Assessment: Identify potential hazards such as electrical lines, gas leaks, and unstable surfaces

9. Explain the importance of proper record-keeping in sleeve facing projects.

Comprehensive record-keeping is essential for:

- Documentation: Provides a detailed account of the project’s scope, materials used, and installation procedures

- Quality Control: Enables the verification of material specifications, testing results, and adherence to industry standards

- Future Reference: Serves as a valuable resource for future maintenance, repairs, or inspections

- Legal Considerations: Protects against potential disputes or liability issues

10. How do you collaborate with other trades and professionals on sleeve facing projects?

Effective collaboration is crucial:

- Coordination: Participate in project planning meetings to ensure proper scheduling and resource allocation

- Communication: Maintain open communication channels to address any issues or changes promptly

- Knowledge Sharing: Share expertise and learn from other professionals to enhance the project outcome

- Respect and Understanding: Acknowledge the roles and responsibilities of other trades to foster a positive work environment

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Sleeve Facing Sewer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Sleeve Facing Sewer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Sleeve Facing Sewer is a professional who specializes in sewing and assembling sleeves and facings for garments. Their key job responsibilities include:

1. Sleeve Construction

Sleeves are an important part of any garment, and they can be quite complex to sew. Sleeve Facing Sewers must be able to accurately follow patterns and instructions in order to create sleeves that fit well and look professional.

- Cutting and preparing sleeve fabric

- Sewing sleeve seams

- Attaching sleeves to the garment body

- Inserting zippers or other closures

2. Facing Construction

Facings are used to finish the edges of garments and to provide a clean, professional look. Sleeve Facing Sewers must be able to sew facings that are even and precise.

- Cutting and preparing facing fabric

- Sewing facing seams

- Attaching facings to the garment

- Finishing facings

3. Quality Control

Sleeve Facing Sewers must be able to inspect their work and identify any errors. They must also be able to correct errors and ensure that the final product meets the required standards.

- Inspecting sleeves and facings for defects

- Correcting errors

- Ensuring that the final product meets the required standards

4. Teamwork

Sleeve Facing Sewers often work as part of a team of other garment makers. They must be able to communicate effectively with their team members and work together to achieve the desired results.

- Communicating with team members

- Working together to achieve the desired results

Interview Tips

Preparing for an interview can be daunting, but there are some things you can do to increase your chances of success.

1. Research the Company and the Position

Before you go to an interview, it’s important to do your research. Learn as much as you can about the company and the position you’re applying for. This will help you to understand the company’s culture and values, and to tailor your answers to the specific requirements of the job.

- Visit the company’s website

- Read articles about the company in the news

- Talk to people who work at the company

2. Practice Your Answers to Common Interview Questions

There are a few common interview questions that you’re likely to be asked, such as “Tell me about yourself” and “Why are you interested in this job?” It’s helpful to practice your answers to these questions in advance so that you can deliver them confidently and concisely.

- Write down your answers to common interview questions

- Practice saying your answers out loud

- Get feedback from a friend or family member

3. Dress Professionally

First impressions matter, so it’s important to dress professionally for your interview. This means wearing clean, pressed clothes that are appropriate for the office environment.

- Wear a suit or dress pants and a button-down shirt

- Make sure your clothes are clean and pressed

- Avoid wearing strong fragrances

4. Be Punctual

Punctuality is important for any interview, but it’s especially important for a Sleeve Facing Sewer interview. This shows the interviewer that you’re reliable and that you respect their time.

- Plan your route to the interview in advance

- Give yourself plenty of time to travel

- Arrive at the interview on time

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Sleeve Facing Sewer interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.