Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Stitch Bonding Machine Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

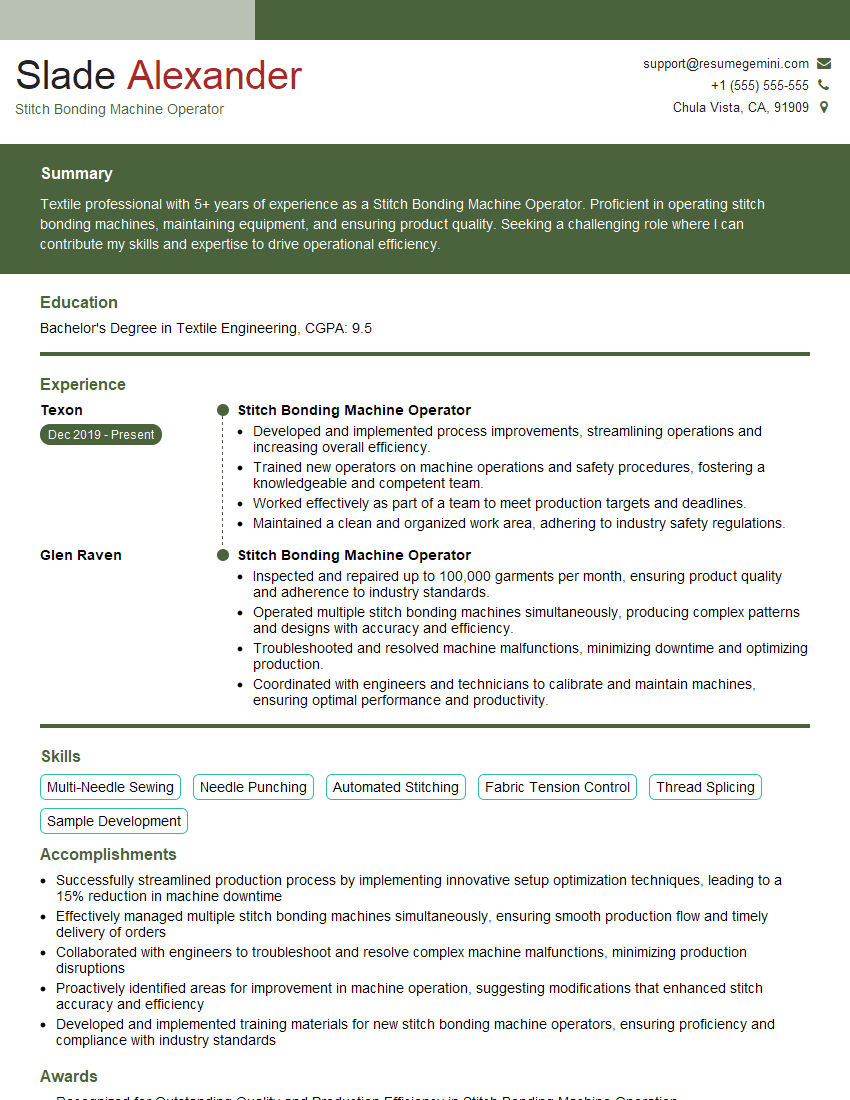

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Stitch Bonding Machine Operator

1. Explain the different types of stitch bonding machines and their key differences. Describe the applications and advantages of each type?

There are three primary types of stitch bonding machines:

- Chain stitch machines: Create a continuous, interlooping chain stitch. Suitable for lightweight fabrics, elastics, and lace, offering high seam strength and elasticity.

- Warp knit machines: Produce a flat, knitted fabric from a series of warp yarns. Used for sportswear, outerwear, and industrial fabrics, providing flexibility and comfort.

- Raschel knit machines: Create a lace-like fabric with a variety of patterns and textures. Ideal for lingerie, curtains, and decorative materials, offering intricate designs and breathability.

2. How do you ensure consistent stitch quality on a stitch bonding machine?

Quality Control Measures

- Regularly check needle sharpness and tension.

- Inspect thread tension and adjust settings as needed.

- Calibrate the machine’s stitch length and width.

- Monitor fabric tension to prevent puckering or stretching.

Preventive Maintenance

- Lubricate machine components regularly.

- Clean the machine head and thread path to remove lint and debris.

- Replace worn parts, such as needles and bobbins, promptly.

Training and Skillsets

- Train operators on proper machine operation and maintenance.

- Ensure operators have a keen eye for detail and a commitment to quality.

3. What are the common causes of fabric defects in stitch bonding and how do you troubleshoot them?

Fabric defects can arise from various causes, including:

- Missed stitches: Caused by incorrect needle timing or improper thread tension. Adjust needle timing and check thread tension.

- Slack stitches: Resulting from loose thread tension or worn needles. Increase thread tension and replace needles.

- Puckering: Occurs when the fabric is too tightly stretched. Reduce fabric tension to prevent gathers.

- Broken threads: Caused by sharp fabric edges, worn needles, or improper threading. Identify the source of thread breakage and resolve the issue.

- Color variation: May indicate incorrect dye batching or machine malfunction. Consult with the dye supplier and check machine settings.

4. How do you handle machine downtime and maintain production efficiency?

To minimize downtime and maintain production efficiency:

- Preventive maintenance: Regularly service and calibrate machines to identify and address potential issues before they cause downtime.

- Spare parts inventory: Maintain a stock of critical spare parts, such as needles, bobbins, and belts, to facilitate quick repairs.

- Cross-training: Train operators on multiple machines to ensure backup coverage in case of breakdowns.

- Rapid response: Establish a clear system for reporting and responding to equipment malfunctions to minimize downtime.

5. What is your experience with different types of stitch bonding patterns and how do you select the appropriate pattern for a given application?

I have experience with a range of stitch bonding patterns, including:

- Plain stitch: Creates a simple, straight stitch for basic fabrics.

- Zigzag stitch: Provides increased stretch and seam strength, suitable for stretchy materials.

- Overlock stitch: Used to finish fabric edges, preventing fraying.

- Coverstitch: Creates a decorative stitch that conceals the raw edge of a fabric.

To select the appropriate pattern for an application, I consider factors such as the fabric type, intended use, and desired seam properties, ensuring optimal performance and durability.

6. Describe the safety procedures and regulations you follow when operating stitch bonding machines.

- Wear appropriate safety gear, including gloves and eye protection.

- Keep hands away from moving parts and needles.

- Ensure the machine is properly grounded to prevent electrical hazards.

- Follow lockout/tagout procedures before performing maintenance or repairs.

- Report any safety concerns or hazards to a supervisor immediately.

7. What is your understanding of the quality control standards for stitch bonded fabrics and how do you ensure compliance?

Quality control standards for stitch bonded fabrics include:

- Stitch density: Number of stitches per unit length, ensuring fabric strength and durability.

- Seam strength: Resistance of a seam to tearing or breaking.

- Fabric appearance: Free from defects, such as wrinkles, puckers, or color variations.

To ensure compliance, I perform regular inspections and testing of fabrics, utilizing measuring instruments and visual assessments. Any deviations from standards are documented and corrective actions are implemented promptly.

8. How do you manage production schedules and prioritize tasks to meet deadlines?

- Detailed planning: Review production schedules and identify critical deadlines.

- Prioritization: Assign priority levels to tasks based on importance and urgency.

- Collaboration: Communicate with colleagues and supervisors to coordinate tasks and avoid bottlenecks.

- Time management: Efficiently allocate time to each task, avoiding delays.

- Flexibility: Adjust priorities and schedules when unexpected events occur.

9. Explain the maintenance and repair procedures for stitch bonding machines.

Regular Maintenance

- Clean and lubricate machine components regularly.

- Check and adjust thread tension and needle timing.

- Inspect and replace worn parts, such as needles and bobbins.

Repair Procedures

- Identify the source of the malfunction through troubleshooting.

- Follow manufacturer’s instructions for repairs, using appropriate tools and techniques.

- Test the repaired machine to ensure proper functionality before returning it to production.

10. How do you stay up-to-date with the latest advancements in stitch bonding technology?

- Attend industry conferences and trade shows.

- Read technical journals and articles.

- Network with other professionals in the field.

- Seek training and certification opportunities.

- Explore online resources and manufacturer websites.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Stitch Bonding Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Stitch Bonding Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Stitch Bonding Machine Operator is responsible for operating and maintaining stitch bonding machines used in the production of nonwoven fabrics. The key job responsibilities include:

1. Machine Operation and Maintenance

Operating stitch bonding machines to produce nonwoven fabrics according to specified production orders.

- Monitoring machine operations and making necessary adjustments to ensure optimal performance.

- Performing routine maintenance and repairs on stitch bonding machines to prevent breakdowns and ensure smooth operation.

2. Material Handling

Loading and unloading raw materials (fibers, yarns) and finished products from stitch bonding machines.

- Inspecting raw materials to ensure they meet quality standards.

- Storing and handling materials safely and efficiently.

3. Quality Control

Monitoring the quality of nonwoven fabrics produced by stitch bonding machines.

- Conducting visual inspections and performing tests to assess fabric quality.

- Identifying and correcting defects in the production process.

4. Safety and Compliance

Following safety guidelines and regulations related to stitch bonding machine operation and work environment.

- Wearing appropriate personal protective equipment.

- Maintaining a clean and organized work area.

- Adhering to environmental regulations and waste management procedures.

Interview Tips

To ace an interview for a Stitch Bonding Machine Operator position, candidates should prepare thoroughly and demonstrate their skills and experience. Here are some tips:

1. Research the Company and Position

Familiarize yourself with the company’s history, values, and products. Understand the specific requirements of the Stitch Bonding Machine Operator role.

- Visit the company’s website and social media pages.

- Review the job description thoroughly.

2. Highlight Relevant Skills and Experience

Emphasize your proficiency in operating and maintaining stitch bonding machines. Showcase your knowledge of nonwoven fabric production processes.

- Provide specific examples of your accomplishments in previous roles.

- Quantify your results whenever possible, using metrics such as increased production efficiency or reduced waste.

3. Demonstrate Attention to Detail and Problem-Solving Skills

Stress your ability to monitor machine operations closely and identify potential issues. Highlight your problem-solving abilities and how you have resolved production challenges in the past.

- Share examples of situations where you detected and fixed machine malfunctions.

- Describe how you have implemented improvements to production processes.

4. Be Prepared for Technical Questions

Expect questions about the operation and maintenance of stitch bonding machines. Study the principles of stitch bonding technology and be ready to discuss common troubleshooting procedures.

- Review technical manuals or online resources related to stitch bonding machines.

- Practice answering questions about machine components, adjustments, and maintenance.

5. Show Enthusiasm and Safety Consciousness

Convey your passion for nonwoven fabric production and your commitment to safety. Highlight your understanding of the industry’s safety regulations and your adherence to best practices.

- Express your eagerness to contribute to the company’s production goals.

- Emphasize your commitment to maintaining a safe and efficient work environment.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Stitch Bonding Machine Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.