Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Two Needle Machine Operator interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Two Needle Machine Operator so you can tailor your answers to impress potential employers.

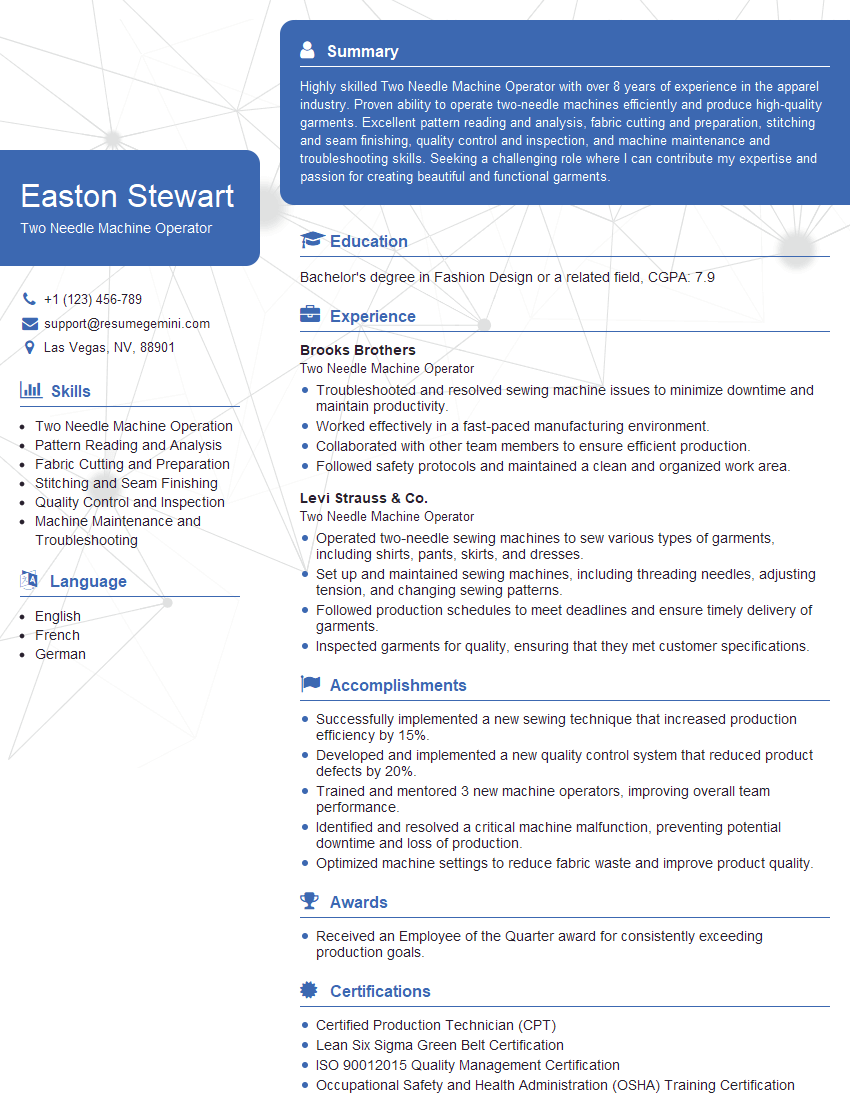

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Two Needle Machine Operator

1. What are the different types of two-needle machines?

There are two main types of two-needle machines: flatbed and cylinder. Flatbed machines are used for sewing flat pieces of fabric, while cylinder machines are used for sewing tubular pieces of fabric, such as sleeves and pants legs.

2. What are the different types of stitches that can be sewn on a two-needle machine?

Straight stitch

- This is the most basic stitch and is used for seams, hems, and darts.

Zigzag stitch

- This stitch is used for finishing edges, preventing fraying, and creating decorative effects.

Overlock stitch

- This stitch is used for finishing edges and preventing fraying on stretchy fabrics.

Cover stitch

- This stitch is used for creating a stretchy, decorative finish on seams.

3. What are the different types of thread that can be used on a two-needle machine?

- Cotton thread is the most common type of thread used on two-needle machines. It is strong and durable, and it comes in a variety of colors.

- Polyester thread is a synthetic thread that is stronger than cotton thread. It is also more resistant to fading and fraying.

- Nylon thread is a very strong and elastic thread. It is often used for sewing stretch fabrics.

4. What are the different types of fabric that can be sewn on a two-needle machine?

- Two-needle machines can sew a variety of fabrics, including cotton, polyester, nylon, and spandex.

- The type of fabric that can be sewn on a two-needle machine will depend on the type of stitch that is being used.

- For example, a straight stitch can be used to sew most types of fabric, while a zigzag stitch is best suited for sewing stretchy fabrics.

5. What are the different types of needles that can be used on a two-needle machine?

- There are a variety of different needles that can be used on a two-needle machine, depending on the type of fabric that is being sewn.

- Some of the most common types of needles include:

- Universal needles

- Stretch needles

- Denim needles

- Leather needles

- It is important to choose the correct type of needle for the fabric that is being sewn in order to prevent damage to the fabric or the machine.

6. What are the different types of feet that can be used on a two-needle machine?

- There are a variety of different feet that can be used on a two-needle machine, depending on the type of stitch that is being sewn.

- Some of the most common types of feet include:

- Presser foot

- Walking foot

- Blind hem foot

- Zipper foot

- Buttonhole foot

- It is important to choose the correct type of foot for the stitch that is being sewn in order to ensure that the stitch is sewn correctly.

7. How do you troubleshoot a two-needle machine?

- If a two-needle machine is not sewing correctly, there are a few things that you can do to troubleshoot the problem.

- First, check the thread tension. The thread tension should be tight enough to prevent the thread from breaking, but not so tight that it causes the fabric to pucker.

- Next, check the needles. The needles should be sharp and free of burrs. If the needles are dull or damaged, they will need to be replaced.

- Finally, check the fabric. The fabric should be free of wrinkles and tears. If the fabric is wrinkled or torn, it can cause the machine to sew incorrectly.

8. How do you maintain a two-needle machine?

- To maintain a two-needle machine, it is important to clean and oil the machine regularly.

- The machine should be cleaned with a soft cloth and a mild detergent. The oil should be applied to the moving parts of the machine.

- In addition, the machine should be inspected regularly for any signs of wear or damage. If any problems are found, they should be repaired immediately.

9. What are the safety precautions that should be taken when operating a two-needle machine?

- When operating a two-needle machine, it is important to take the following safety precautions:

- Always wear safety glasses.

- Never reach into the machine while it is running.

- Keep your hands away from the needles.

- Unplug the machine before making any adjustments.

- Follow all of the manufacturer’s instructions for safe operation.

10. What are the different types of projects that can be sewn on a two-needle machine?

- Two-needle machines can be used to sew a variety of projects, including:

- Clothing

- Home décor

- Accessories

- Bags

- Upholstery

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Two Needle Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Two Needle Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Two Needle Machine Operators are responsible for operating two-needle sewing machines to sew seams in garments, accessories, and other textile products. They work under precise instructions, following established patterns and specifications, to ensure the proper execution of stitching details and quality standards.

1. Machine Operation and Maintenance

Operate and maintain two-needle sewing machines, ensuring proper tension, needle and thread selection, and machine calibration to achieve precise stitching.

- Monitor machine performance, identify and resolve minor issues promptly to maintain efficiency.

- Perform regular machine maintenance tasks, including cleaning, lubrication, and basic troubleshooting.

2. Production Standards and Quality Control

Adhere to production targets and quality standards, ensuring that garments meet specifications and customer expectations.

- Inspect finished products for defects and ensure compliance with established quality parameters.

- Participate in quality control processes, such as checking fabric quality, thread tension, and seam strength.

3. Fabric Handling and Material Management

Handle and manage a variety of fabrics, including delicate materials, ensuring proper handling and storage to prevent damage.

- Determine appropriate thread and needle combinations based on fabric type and stitching requirements.

- Maintain a clean and organized work area, following established material handling procedures.

4. Communication and Teamwork

Effectively communicate with supervisors, colleagues, and quality control personnel to ensure smooth production processes.

- Work as part of a team to achieve production goals and maintain a positive work environment.

- Provide feedback and suggestions for process improvements to enhance efficiency and quality.

Interview Tips

Preparing thoroughly for an interview can significantly increase your chances of success. Here are some tips to help you ace your interview for a Two Needle Machine Operator position:

1. Research the Company and Role

Take the time to research the company you’re applying to and the specific Two Needle Machine Operator role. This will help you understand the company’s culture, values, and expectations for the position. This knowledge can help you tailor your answers to the interviewer’s questions and demonstrate your enthusiasm for the job.

- Visit the company’s website to learn about their products, services, and mission statement.

- Read industry publications and articles to stay up-to-date on the latest advancements in sewing technology.

2. Practice Your Answers

Anticipate common interview questions and practice your answers beforehand. This will help you feel more confident and prepared during the interview, allowing you to articulate your skills and experience effectively.

- Prepare for questions about your technical skills, such as your proficiency in operating two-needle sewing machines and your knowledge of different fabrics and stitching techniques.

- Be ready to discuss your experience in maintaining and troubleshooting sewing machines.

3. Highlight Your Attention to Detail

Two Needle Machine Operators play a crucial role in ensuring the quality of garments and other textile products. Emphasize your attention to detail and your ability to produce precise and consistent stitching.

- Describe examples of how you have maintained high levels of accuracy and quality in your previous roles.

- Explain how you handle delicate fabrics and materials with care and precision.

4. Showcase Your Teamwork and Communication Skills

Two Needle Machine Operators often work in a team environment and communicate with various individuals, including supervisors and quality control personnel. Highlight your teamwork skills and ability to collaborate effectively.

- Share examples of how you have worked as part of a team to achieve production goals.

- Describe how you have communicated effectively with colleagues to resolve issues and maintain a positive work environment.

5. Be Enthusiastic and Positive

Your enthusiasm for the job and your positive attitude can make a lasting impression on the interviewer. Demonstrate your passion for sewing and your desire to contribute to the company’s success.

- Express your interest in the company’s products and services and explain how your skills and experience align with their needs.

- Convey your commitment to quality and your willingness to go the extra mile to ensure customer satisfaction.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Two Needle Machine Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.