Are you gearing up for a career in Vest Finisher? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Vest Finisher and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

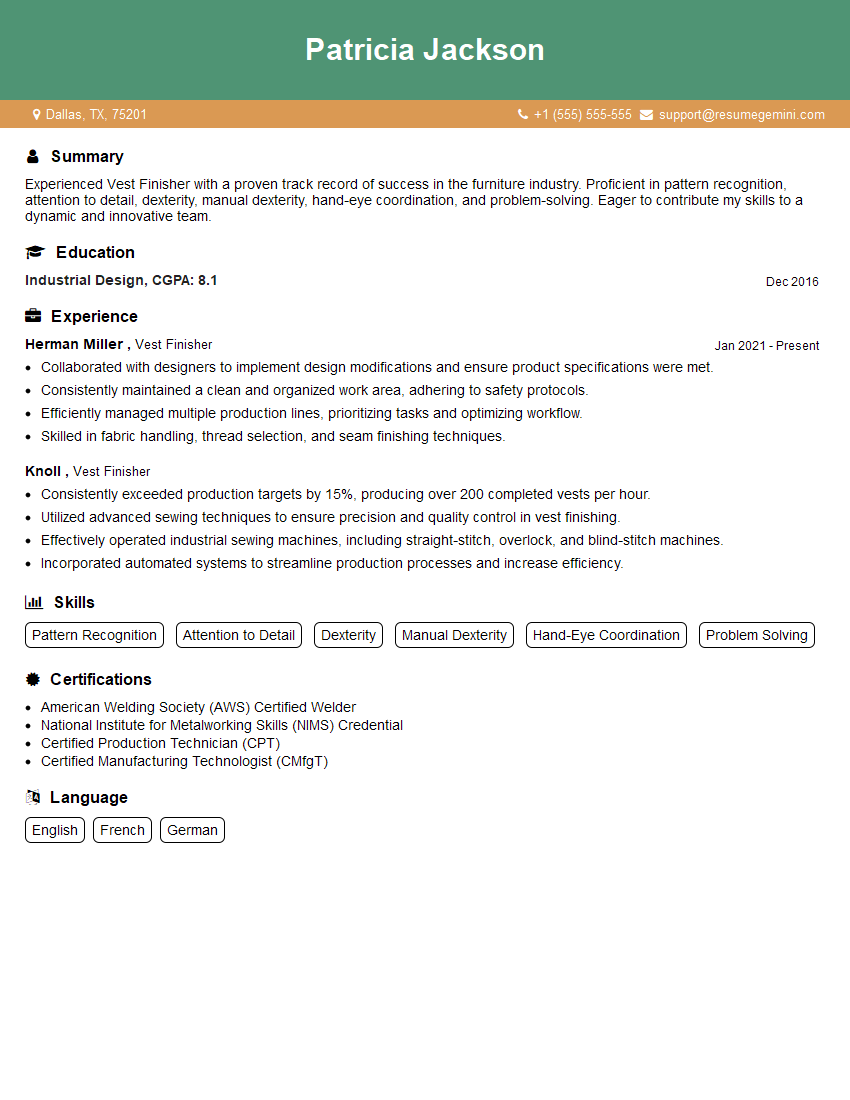

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Vest Finisher

1. Explain the process of finishing a vest in detail.

- Vest finishing involves several steps to refine and enhance the garment’s appearance and quality.

- After sewing the vest, it undergoes pre-pressing to remove any wrinkles or creases.

- Fusing is done to bond interlining materials to the vest to provide structure and shape.

- Buttonholes are carefully created and reinforced.

- Buttons are then attached securely.

- The vest is pressed again to set the seams and give it a polished look.

- Quality control checks are performed to ensure the vest meets the desired standards.

- Packaging is done to protect the vest during storage and transportation.

2. What are the different types of vest finishing techniques?

Types of Finishing Techniques

- Hand Finishing: Involves meticulous attention to detail, often used for high-end vests.

- Machine Finishing: Employs specialized machinery to increase productivity and efficiency.

Examples of Specific Techniques

- Edgestitching: Decorative stitching along the edges of the vest.

- Topstitching: Visible stitching on the outer fabric to enhance details and design.

- Hemming: Folding and securing the edges of the vest to prevent fraying.

- Buttonhole Making: Creating openings for buttons using specialized equipment.

- Button Attachment: Sewing or attaching buttons securely to the vest.

3. What equipment is used for vest finishing?

- Industrial Sewing Machines: Used for constructing and assembling the vest.

- Pressing Equipment: Irons, steam presses, and fusing machines for shaping and setting seams.

- Buttonhole Machines: Specialized machines for creating buttonholes.

- Button Attaching Machines: Automated or semi-automated machines for attaching buttons.

- Steam Tunnels and Dryers: Used for drying and setting the finished vest.

- Quality Control Tools: Measuring tapes, gauges, and inspection lights for ensuring accuracy.

- Material Handling Equipment: Conveyors and carts for moving vests through the finishing process.

4. What are the challenges in vest finishing and how do you overcome them?

- Fabric Handling: Managing delicate or slippery fabrics requires precision and care.

- Accuracy and Consistency: Ensuring uniformity and meeting quality standards is crucial.

- Equipment Maintenance: Regular maintenance and calibration of equipment is essential for optimal performance.

- Time Constraints: Meeting production deadlines while maintaining quality can be challenging.

- Overcoming these challenges involves:

- Using the right techniques and equipment for specific fabrics.

- Implementing quality control measures throughout the process.

- Performing regular equipment maintenance and training.

- Planning and optimizing production processes to meet deadlines.

5. How do you ensure the quality of the finished vest?

- Inspection Throughout the Process: Regular checks at each stage of finishing.

- Adherence to Specifications: Following established standards and guidelines.

- Use of Quality Materials: Sourcing high-quality fabrics and components.

- Skilled Workforce: Experienced and trained finishers ensure attention to detail.

- Final Inspection: Thorough examination of the finished vest before packaging.

- Customer Feedback: Gathering feedback to identify areas for improvement.

6. What are the safety precautions that must be followed during vest finishing?

- Proper Machine Operation: Following safety guidelines for equipment use.

- Handling Sharp Objects: Using caution when working with needles, scissors, and cutting tools.

- Ergonomics: Maintaining proper posture and avoiding repetitive motions.

- Use of Personal Protective Equipment: Wearing safety glasses, gloves, and appropriate clothing.

- Housekeeping: Keeping the work area clean and organized to prevent hazards.

- Emergency Procedures: Knowing and following emergency protocols in case of accidents.

7. How do you stay updated with the latest trends and techniques in vest finishing?

- Industry Events and Trade Shows: Attending events to learn about new technologies and trends.

- Online Resources: Reading industry publications, websites, and forums for updates.

- Training and Workshops: Participating in training programs and workshops to enhance skills.

- Collaboration with Colleagues: Exchanging knowledge and best practices with other vest finishers.

- Customer Feedback: Listening to customer feedback to identify changing demands and preferences.

8. How do you prioritize tasks and manage your time effectively during vest finishing?

- Prioritizing Tasks: Identifying the most critical tasks and focusing on them first.

- Time Management Techniques: Using techniques like the Pomodoro Technique or time blocking.

- Delegation: Assigning tasks to colleagues to maximize productivity.

- Streamlining Processes: Identifying and improving inefficient processes to save time.

- Minimizing Distractions: Creating a dedicated workspace and minimizing interruptions.

9. How do you handle working under pressure and meeting deadlines in vest finishing?

- Staying Calm and Focused: Maintaining composure and prioritizing tasks under pressure.

- Effective Time Management: Utilizing time management techniques to maximize productivity.

- Communication: Regularly updating supervisors and colleagues on progress and potential challenges.

- Seeking Support: Asking for assistance from colleagues or supervisors when needed.

- Learning from Mistakes: Analyzing past experiences to identify areas for improvement and prevent future delays.

- Maintaining a Positive Attitude: Staying positive and motivated even during stressful times.

10. How do you work as part of a team in vest finishing?

- Collaboration: Communicating effectively with team members and sharing knowledge.

- Support: Providing assistance to colleagues and seeking help when needed.

- Respecting Differences: Valuing diverse perspectives and working together harmoniously.

- Constructive Feedback: Giving and receiving feedback to improve individual and team performance.

- Common Goals: Working towards shared objectives and prioritizing team success.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Vest Finisher.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Vest Finisher‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Vest Finishers are responsible for the final inspection, finishing, and preparation of garments for shipment or retail display.

1. Quality Inspection

Inspect garments for any defects or errors, such as uneven stitching, loose threads, or incorrect labeling.

- Use quality control checklists to ensure all garment specifications are met.

- Identify and report any issues to the appropriate supervisor or quality control personnel.

2. Finishing Touches

Perform finishing touches to improve the garment’s appearance and presentation.

- Steam or iron garments to remove wrinkles and creases.

- Trim loose threads and remove any excess fabric or tags.

3. Packaging and Preparation

Package and prepare garments for shipment or display.

- Hang garments on hangers and attach garment labels.

- Fold and package garments according to specified guidelines.

- Prepare shipping documents and ensure garments are properly labeled and packed for delivery.

4. Machine Operation

Operate specialized machinery used in garment finishing, such as steamers, irons, and tagging machines.

- Follow safety protocols and maintain equipment in good working condition.

- Adjust machine settings to achieve optimal finishing results.

Interview Tips

Preparing for an interview for a Vest Finisher position requires thorough research, practice, and a professional demeanor. Here are some tips to help candidates ace their interview:

1. Research the Company and Position

Familiarize yourself with the company’s history, values, and products. Understand the specific responsibilities and requirements of the Vest Finisher role.

- Check the company’s website, social media accounts, and industry reports.

- Read job descriptions carefully and identify key skills and qualifications.

2. Highlight Relevant Skills and Experience

Emphasize your experience in garment inspection, finishing, packaging, and machine operation. Quantify your accomplishments whenever possible.

- Provide examples of your attention to detail and ability to identify and resolve quality issues.

- Share instances where you improved efficiency and reduced errors in finishing processes.

3. Demonstrate Professionalism and Enthusiasm

Present yourself professionally, dress appropriately, and maintain good eye contact throughout the interview.

- Be punctual and respectful of the interviewer’s time.

- Project a positive attitude and enthusiasm for the Vest Finisher role.

4. Practice Common Interview Questions

Prepare for common interview questions by practicing your responses. Consider questions related to your experience, skills, and motivation.

- Anticipate questions about garment defect identification, finishing techniques, and packaging procedures.

- Be ready to discuss your understanding of quality control standards and safety protocols.

5. Ask Thoughtful Questions

Asking well-informed questions at the end of the interview shows your interest and engagement.

- Inquire about the company’s growth plans or sustainability initiatives.

- Ask about opportunities for professional development and advancement.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Vest Finisher interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!