Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Luggage Maker position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

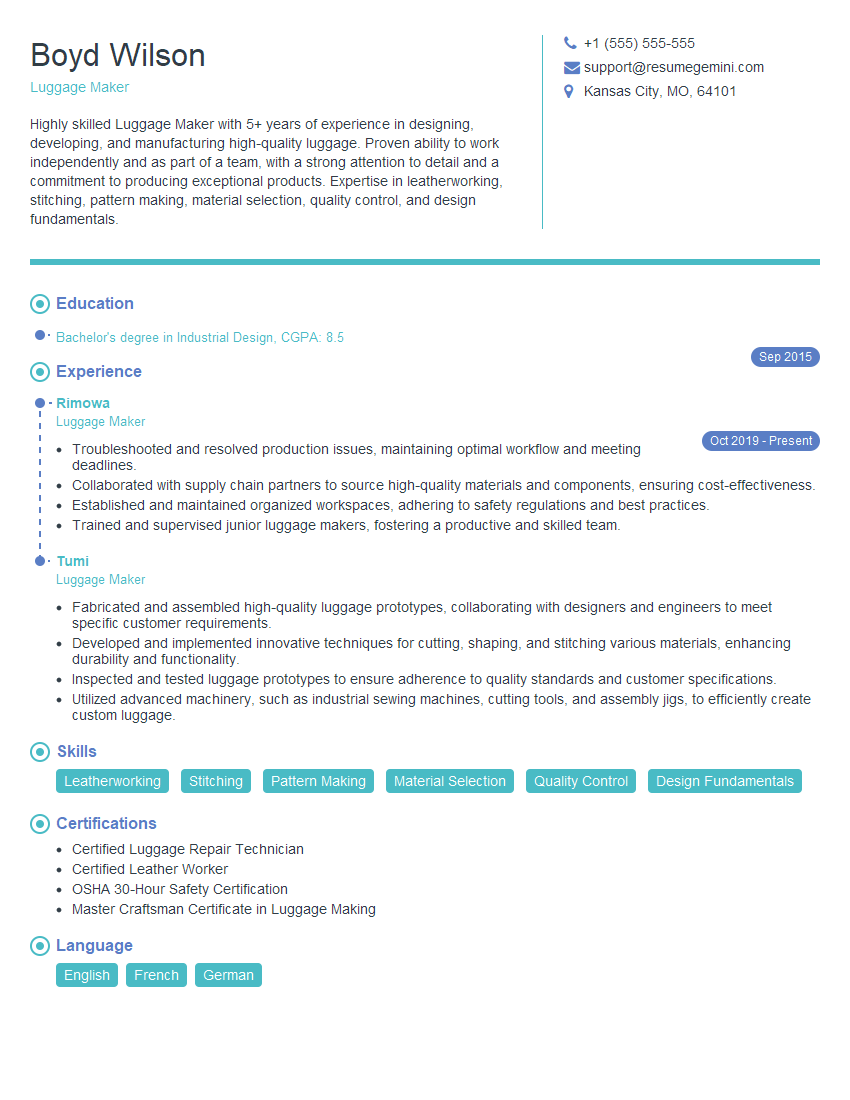

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Luggage Maker

1. How do you ensure that the luggage is durable and can withstand rough handling?

To ensure the durability of luggage, I employ a combination of techniques:

- Material Selection: I use high-quality, durable materials such as polycarbonate, nylon, or canvas that can withstand impact, abrasion, and weather conditions.

- Construction Methods: I pay attention to the construction methods, ensuring that seams are reinforced, zippers are heavy-duty, and handles are securely attached.

- Testing: I conduct rigorous testing, including drop tests, abrasion tests, and water resistance tests, to ensure that the luggage meets industry standards and exceeds customer expectations.

2. What types of materials are you proficient in working with for luggage construction?

Hard-Shell Luggage

- Polycarbonate

- ABS Plastic

- Fiberglass

Soft-Shell Luggage

- Nylon

- Canvas

- Polyester

Other Materials

- Leather

- Metal

- Wood

3. How do you design luggage to be both functional and aesthetically pleasing?

To achieve a balance between functionality and aesthetics, I follow these principles:

- User Needs Analysis: I consider the target audience and their specific needs, such as storage capacity, organization features, and durability requirements.

- Ergonomic Design: I design luggage with comfort in mind, ensuring handles are comfortable to grip, shoulder straps are adjustable, and the overall weight is optimized.

- Aesthetic Appeal: I incorporate design elements such as unique textures, patterns, and colors to enhance the visual appeal of the luggage while maintaining its functionality.

4. How do you stay up-to-date with the latest advancements in luggage manufacturing technology?

To stay abreast of industry advancements, I engage in several practices:

- Industry Trade Shows and Conferences: I attend industry events to learn about new materials, manufacturing techniques, and design trends.

- Research and Development: I conduct my own research and development to explore innovative materials and technologies that can enhance luggage quality and functionality.

- Collaboration with Suppliers: I collaborate with suppliers and manufacturers to gain insights into the latest advancements and incorporate them into my designs.

5. How do you handle customer feedback and incorporate it into your luggage designs?

I value customer feedback as a vital tool for improvement:

- Feedback Collection: I actively seek customer feedback through surveys, reviews, and social media interactions.

- Analysis and Interpretation: I analyze feedback to identify common issues, feature requests, and areas for improvement.

- Design Refinement: I incorporate feedback into my designs by making adjustments to materials, features, or aesthetics to enhance user satisfaction.

6. What are the specific techniques you use to ensure that zippers on luggage are durable and reliable?

- Zipper Selection: I select high-quality zippers from reputable suppliers, ensuring they are made from durable materials.

- Reinforced Seams: I reinforce the seams around zippers with multiple layers of fabric or webbing to prevent tearing.

- Metal Teeth: I prefer zippers with metal teeth rather than plastic teeth, as they are more robust and less prone to breakage.

- Regular Lubrication: I recommend regular lubrication of zippers to maintain smooth operation and prevent jamming.

7. How do you design and construct luggage to meet specific size and weight restrictions imposed by airlines?

To design luggage that complies with airline regulations, I follow these steps:

- Research and Compliance: I research and stay updated on the latest airline size and weight restrictions.

- Design Optimization: I carefully plan the dimensions and weight distribution of the luggage to maximize storage space while meeting airline requirements.

- Material Selection: I use lightweight materials, such as polycarbonate or nylon, to reduce the overall weight of the luggage.

- Testing and Certification: I conduct thorough testing to ensure that the luggage meets the specified size and weight limits before releasing it for production.

8. What techniques do you employ to make luggage water-resistant or waterproof?

- Water-Resistant Coatings: I apply water-resistant coatings to the exterior fabric or use materials that are naturally water-repellent.

- Sealed Seams: I seal the seams and zippers using waterproof adhesives or tapes to prevent water seepage.

- Interior Linings: I use water-resistant or waterproof linings to protect the contents of the luggage from moisture.

- Testing and Certification: I conduct water resistance tests to ensure that the luggage meets or exceeds industry standards.

9. How do you design and construct luggage to withstand the rigors of travel, such as rough handling and transportation?

- Durable Materials: I use strong and impact-resistant materials, such as polycarbonate or ABS plastic, to withstand rough handling.

- Reinforced Corners and Edges: I reinforce the corners and edges of the luggage to protect them from damage during transportation or accidental drops.

- Protective Bezels: I incorporate protective bezels around wheels and handles to prevent them from being damaged during transit.

- Stress Testing: I conduct stress tests to ensure that the luggage can withstand the physical demands of travel.

10. What are the key considerations when designing luggage for different types of travel, such as business trips, family vacations, or adventure travel?

To design luggage tailored to different travel needs, I consider the following factors:

- Business Trips: Luggage for business trips should prioritize organization, durability, and professional appearance, with features like padded laptop compartments and removable suiters.

- Family Vacations: Luggage for family vacations should have ample storage capacity, be easy to maneuver, and include child-friendly features like separate compartments for toys or snacks.

- Adventure Travel: Luggage for adventure travel should be rugged, weather-resistant, and adaptable to different terrains, with features like backpack straps or removable harnesses.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Luggage Maker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Luggage Maker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Luggage Makers are responsible for the creation and maintenance of luggage, ensuring its durability, functionality, and aesthetic appeal. Their key responsibilities include:

1. Crafting Luggage

Luggage Makers use various materials like leather, fabric, and plastic to construct luggage according to design specifications. They cut, sew, and assemble components to create suitcases, backpacks, and other luggage items.

- Adhering to design specifications and quality standards.

- Selecting and utilizing appropriate materials.

- Operating and maintaining machinery and equipment.

2. Repairing and Maintaining Luggage

Maintaining the quality and functionality of luggage is crucial. Luggage Makers inspect, diagnose, and repair damaged items, replacing or fixing components as needed.

- Assessing the extent of damage.

- Repairing or replacing damaged parts.

- Conducting routine maintenance and cleaning.

3. Quality Control

Ensuring the quality of luggage is essential. Luggage Makers inspect finished products to ensure they meet standards, identify any defects, and take corrective actions.

- Inspecting luggage for defects in materials, construction, and finish.

- Testing luggage for durability and functionality.

- Providing feedback to improve production processes.

4. Collaboration and Communication

Luggage Makers work closely with designers, engineers, and production teams. They communicate specifications, provide feedback, and collaborate to ensure the seamless production of luggage.

- Collaborating with designers to develop new luggage designs.

- Coordinating with engineers to resolve technical issues.

- Communicating with production teams to ensure efficient production.

Interview Tips

Preparing for a Luggage Maker interview is important to showcase your skills and experience. Here are some tips:

1. Research the Company and Industry

Research the company’s history, products, and market position. Understanding the industry trends and latest advancements in luggage design and manufacturing will impress the interviewer.

- Visit the company’s website and read industry publications.

- Attend industry events and network with professionals.

2. Practice Your Craft

Emphasize your hands-on experience in crafting luggage. Highlight your skills in using various materials, operating machinery, and maintaining quality standards.

- Prepare examples of your best work and be ready to discuss your techniques.

- Demonstrate your knowledge of different luggage styles and their construction.

3. Showcase Your Problem-Solving Abilities

Luggage Makers often encounter challenges in repairing and maintaining luggage. Prepare examples of how you diagnosed and resolved complex issues, highlighting your analytical and problem-solving skills.

- Describe a situation where you identified a recurring defect and implemented a solution.

- Explain how you handled a difficult repair or customization request.

4. Emphasize Teamwork and Communication

Luggage Makers work in collaborative environments. Emphasize your ability to work effectively in a team, communicate clearly, and provide feedback to improve processes.

- Provide examples of how you contributed to team projects or resolved conflicts.

- Demonstrate your written and verbal communication skills.

5. Prepare Questions for the Interviewer

Asking thoughtful questions shows your engagement and interest in the role. Prepare questions about the company’s design philosophy, sustainability initiatives, or future plans.

- Inquire about the company’s commitment to innovation and customer satisfaction.

- Ask about opportunities for professional development and growth within the organization.

Next Step:

Now that you’re armed with the knowledge of Luggage Maker interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Luggage Maker positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini