Are you gearing up for a career in Sample Shoe Inspector and Reworker? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Sample Shoe Inspector and Reworker and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

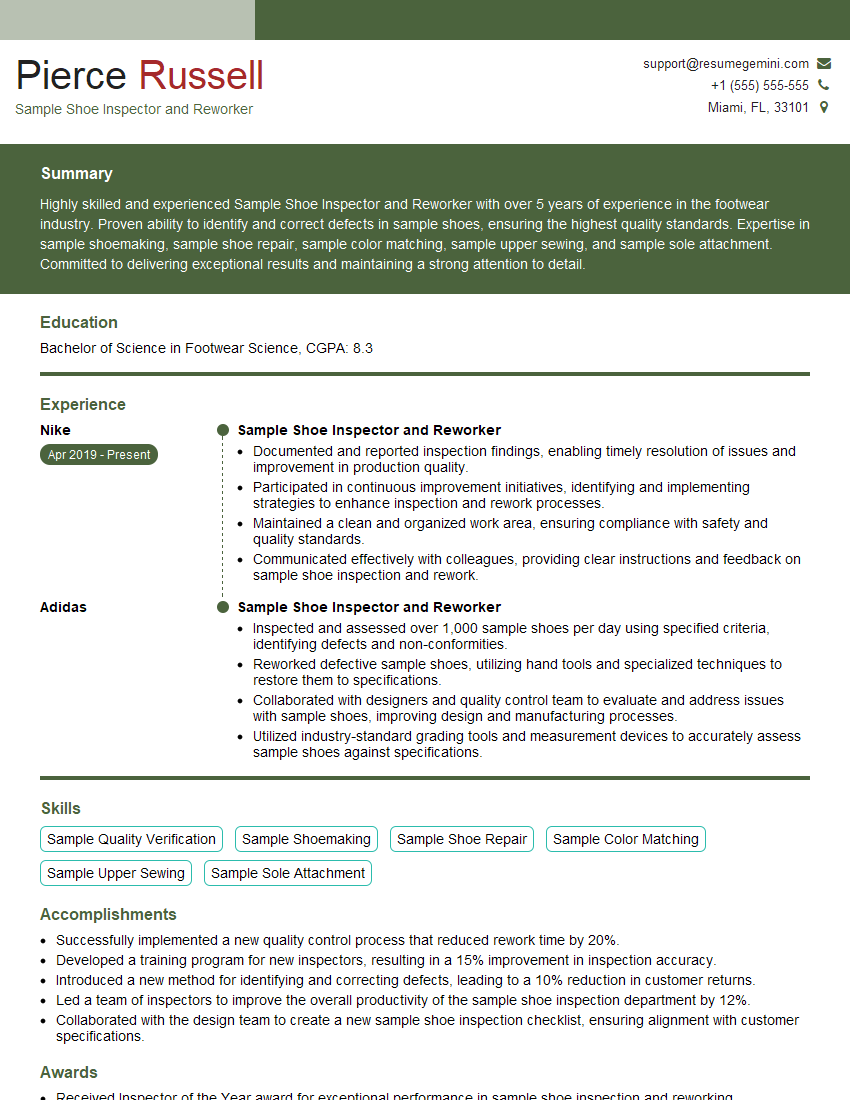

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Sample Shoe Inspector and Reworker

1. What are the key responsibilities of a Sample Shoe Inspector and Reworker?

As a Sample Shoe Inspector and Reworker, I would be responsible for:

- Inspecting sample shoes to ensure they meet quality standards

- Identifying and correcting defects in sample shoes

- Reworking sample shoes to meet customer specifications

- Maintaining accurate records of inspections and repairs

- Working closely with other members of the production team to ensure that shoes are produced to the highest quality standards

2. What are the different types of defects that you can identify in a shoe?

Types of Defects

- Cosmetic defects: These defects affect the appearance of the shoe, but do not affect its functionality. Examples include scratches, scuffs, and uneven stitching.

- Functional defects: These defects affect the functionality of the shoe. Examples include loose soles, broken laces, and faulty zippers.

- Safety defects: These defects pose a safety hazard to the wearer. Examples include sharp edges, protruding nails, and slippery soles.

Identification Techniques

- Visual inspection: This is the most common method of identifying defects. It involves carefully examining the shoe from all angles to look for any visible flaws.

- Physical inspection: This involves touching and manipulating the shoe to check for any defects that cannot be seen visually. For example, you might flex the shoe to check for loose soles or stretch the material to check for tears.

- Functional testing: This involves wearing the shoe or performing specific tests to check for any defects that affect its functionality. For example, you might walk in the shoe to check for any discomfort or instability.

3. What are the different types of materials used in shoe construction, and how do they affect the quality of the shoe?

The different types of materials used in shoe construction include:

- Leather: Leather is a durable and breathable material that is often used for high-quality shoes. It is resistant to water and dirt, and it can be polished to a high shine.

- Suede: Suede is a type of leather that has been sanded to create a soft, velvety finish. It is less durable than leather, but it is more comfortable to wear.

- Canvas: Canvas is a strong and lightweight material that is often used for casual shoes. It is breathable and easy to clean, but it is not as durable as leather.

- Rubber: Rubber is a waterproof and flexible material that is often used for outsoles and midsoles. It provides good traction and cushioning, but it can be heavy.

- Synthetic materials: Synthetic materials are often used to create affordable shoes. They are durable and easy to clean, but they are not as breathable as natural materials.

The quality of the shoe is affected by the type of materials used, as well as the construction methods. Shoes made from high-quality materials and with careful construction will last longer and perform better than shoes made from cheap materials and with poor construction.

4. What are the different steps involved in reworking a shoe?

The different steps involved in reworking a shoe include:

- Identifying the defect

- Determining the best method for repairing the defect

- Gathering the necessary materials and tools

- Making the repair

- Inspecting the repair to ensure that it meets quality standards

The specific steps involved in reworking a shoe will vary depending on the type of defect and the materials used in the shoe.

5. What are the different types of equipment used in shoe inspection and reworking?

The different types of equipment used in shoe inspection and reworking include:

- Magnifying glass: A magnifying glass is used to inspect shoes for small defects that are not visible to the naked eye.

- Micrometer: A micrometer is used to measure the thickness of materials and to ensure that shoes meet the required specifications.

- Pull tester: A pull tester is used to test the strength of materials and to ensure that shoes can withstand the forces that they will be subjected to during wear.

- Sewing machine: A sewing machine is used to repair tears and to stitch new materials into shoes.

- Glue gun: A glue gun is used to adhere materials together and to repair loose soles.

The specific types of equipment used in shoe inspection and reworking will vary depending on the manufacturer and the specific shoes being inspected or reworked.

6. What are the different safety precautions that must be taken when working with shoe inspection and reworking equipment?

The different safety precautions that must be taken when working with shoe inspection and reworking equipment include:

- Always wear appropriate safety gear, such as safety glasses and gloves.

- Never operate equipment unless you have been trained to do so.

- Keep your work area clean and free of debris.

- Never reach into moving machinery.

- Always unplug equipment before performing maintenance or repairs.

By following these safety precautions, you can help to prevent accidents and injuries.

7. What are the different quality control standards that are used in the shoe industry?

The different quality control standards that are used in the shoe industry include:

- ASTM International standards

- ISO standards

- CEN standards

- ANSI standards

- BSI standards

These standards cover a wide range of aspects of shoe quality, including materials, construction, performance, and safety.

8. What are the different types of records that must be kept for shoe inspection and reworking?

The different types of records that must be kept for shoe inspection and reworking include:

- Inspection reports

- Repair records

- Quality control reports

- Training records

- Safety records

These records help to ensure that shoes are produced to the highest quality standards and that all safety regulations are followed.

9. What are the different types of training that are available for Sample Shoe Inspectors and Reworkers?

The different types of training that are available for Sample Shoe Inspectors and Reworkers include:

- On-the-job training

- Classroom training

- Online training

- Vendor training

- Certification training

This training can help Sample Shoe Inspectors and Reworkers to improve their skills and knowledge, and to stay up-to-date on the latest industry standards.

10. What are the different career paths that are available for Sample Shoe Inspectors and Reworkers?

The different career paths that are available for Sample Shoe Inspectors and Reworkers include:

- Quality control manager

- Production supervisor

- Technical trainer

- Sales representative

- Business owner

With experience and additional training, Sample Shoe Inspectors and Reworkers can advance to more senior positions in the shoe industry.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Sample Shoe Inspector and Reworker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Sample Shoe Inspector and Reworker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Sample Shoe Inspectors and Reworkers play a crucial role in maintaining the quality and accuracy of footwear products. Their responsibilities encompass a range of tasks, ensuring that shoes meet the desired specifications and standards.

1. Inspection and Quality Control

Inspectors meticulously examine shoes for any defects or inconsistencies, adhering to established quality control standards. They assess materials, construction, fit, and appearance, ensuring that products meet the desired specifications. Reworkers then address any identified issues, making necessary repairs or adjustments.

- Inspect shoes for defects in materials, craftsmanship, and construction

- Verify color, size, and style accuracy

- Evaluate fit and wearability

- Identify areas for improvement or rework

2. Rework and Repair

Reworkers possess skilled craftsmanship, enabling them to repair and rework shoes to meet the desired quality standards. They may perform a variety of tasks, including repairing damaged materials, replacing faulty components, and making adjustments to ensure a proper fit.

- Repair damaged leather, fabrics, or other materials

- Replace defective components, such as zippers, laces, or buckles

- Make adjustments to improve fit and comfort

- Ensure that reworked shoes meet the same quality standards as new products

3. Documentation and Record Keeping

Inspectors and Reworkers maintain accurate records of their work, documenting any defects identified, repairs made, and any recommendations for further action. This information is crucial for tracking quality trends and identifying areas for process improvement.

- Record inspection findings and repair details

- Maintain records of rework activities and materials used

- Document any recommendations for process improvement or product design

4. Collaboration and Communication

Effective collaboration and communication are essential for Sample Shoe Inspectors and Reworkers. They work closely with designers, production teams, and quality control personnel to ensure that products meet design specifications and quality standards. They also communicate any issues or concerns to relevant stakeholders.

- Collaborate with designers and production teams to identify and resolve product issues

- Communicate inspection and rework findings to quality control personnel

- Provide feedback on product design and manufacturing processes to improve quality

Interview Tips

Preparing for an interview for a Sample Shoe Inspector and Reworker position requires a combination of technical knowledge and interpersonal skills. Here are some tips to help you ace the interview:

1. Research the Company and Role

Take the time to thoroughly research the company and the specific role you are applying for. Understand their product line, quality standards, and company culture. This knowledge will demonstrate your interest in the position and help you answer questions intelligently.

- Visit the company website and read about their products, services, and history.

- Research the specific role and its responsibilities.

- Identify the company’s core values and mission statement.

2. Practice Your Technical Skills

Sample Shoe Inspectors and Reworkers should be proficient in identifying and repairing shoe defects. Practice your inspection techniques and demonstrate your knowledge of shoe construction and materials. Bring examples of your work or explain how you have handled specific quality issues in the past.

- Practice inspecting shoes for defects and identifying the causes.

- Demonstrate your skills in repairing shoes using different techniques.

- Prepare examples of your work or case studies where you have successfully resolved product issues.

3. Highlight Your Attention to Detail and Quality

Employers seek candidates with a meticulous eye for detail and a commitment to quality. Emphasize your ability to inspect shoes thoroughly and identify even the smallest defects. Explain your understanding of quality control standards and how you ensure that products meet those standards.

- Explain how you approach quality inspection and your criteria for identifying defects.

- Describe your experience in implementing quality control measures and ensuring product consistency.

- Share examples of how you have identified and resolved quality issues in the past.

4. Showcase Your Communication and Collaboration Skills

Sample Shoe Inspectors and Reworkers often work as part of a team and must be able to communicate effectively with designers, production personnel, and quality control personnel. Highlight your communication skills, including your ability to clearly convey inspection findings and collaborate with others to resolve issues.

- Describe your experience working in a team environment.

- Explain how you communicate effectively with people from different backgrounds and perspectives.

- Share examples of how you have successfully collaborated with others to resolve problems.

5. Be Enthusiastic and Professional

Demonstrate your enthusiasm for shoes and your commitment to quality. Show the interviewer that you are passionate about your work and eager to contribute to the company’s success. Maintain a professional demeanor throughout the interview and be respectful of your interviewer’s time.

- Express your interest in shoes and your motivation for applying for the position.

- Show that you are a hard worker and that you take pride in your work.

- Be polite and respectful during the interview.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Sample Shoe Inspector and Reworker interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!