Feeling lost in a sea of interview questions? Landed that dream interview for Skate Maker but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Skate Maker interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

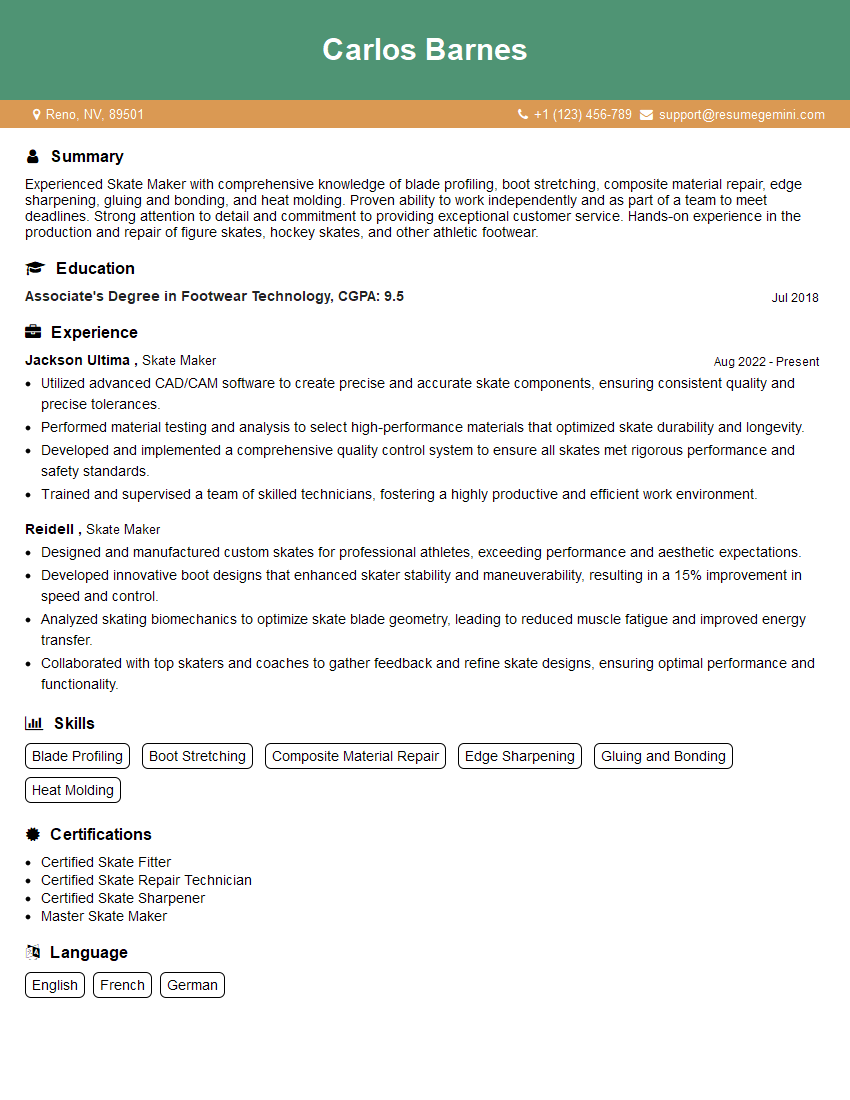

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Skate Maker

1. Describe the primary materials used in the construction of a skateboard and their respective roles?

- Deck: Typically made from 7-9 plies of thin maple wood, providing strength, rigidity, and flexibility.

- Grip Tape: An abrasive material applied to the top of the deck for traction and control.

- Trucks: Metal axles that connect the wheels to the deck, allowing for steering and stability.

- Wheels: Made of polyurethane, they provide grip, cushioning, and durability.

- Bearings: Small precision bearings inside the wheels, reducing friction and allowing for smooth rolling.

2. Explain the different types of skateboards available, including their intended uses and design characteristics?

- Double-kick design for street skating and tricks.

- 7-8.5 inches wide, 28-32 inches long.

- Medium-soft wheels for balance between grip and speed.

- Longer deck, wider trucks, and larger wheels.

- Designed for cruising, carving, and downhill riding.

- Provides stability, smoothness, and speed.

- Single-kick design, shorter length, and wider wheels.

- Suitable for casual riding and commuting.

- Offers maneuverability and portability.

Classic Skateboards:

Longboards:

Cruiser Boards:

3. Describe the process of shaping and laminating a skateboard deck?

Shaping:

- Prepare a wooden blank.

- Trace and cut out the desired shape using a template or CNC machine.

- Sand and refine the edges for a smooth finish.

Laminating:

- Apply glue to the surface of the wooden plies.

- Layer the plies together under pressure in a press machine.

- Cure the glue and allow the deck to bond for several hours.

4. Explain how the assembly and tuning of skateboard components impact its performance?

- Truck Tightness: Adjusts the turning radius and stability.

- Wheel Hardness: Determines grip, speed, and durability.

- Bearing Quality: Affects speed and smoothness.

- Grip Tape Placement: Provides traction and control while riding.

- Optimal Setup: Finding the right combination of components and tuning for the desired riding style.

5. Describe the different techniques used for manufacturing skateboard wheels?

- Injection Molding: Liquid polyurethane is poured into a mold and shaped under pressure.

- Casting: Molten polyurethane is poured into a mold and allowed to cool and solidify.

- Lathe Turning: A block of polyurethane is shaped on a lathe to create a wheel.

- 3D Printing: Additive manufacturing used to create customized or complex wheel designs.

6. Explain the importance of quality control measures in skate making and how they are implemented?

- Material Inspection: Checking the quality of raw materials before use.

- Process Control: Monitoring and adjusting production processes to ensure consistency.

- Product Testing: Evaluating finished skateboards for performance and safety.

- Documentation and Traceability: Tracking production records and product information for recalls or improvements.

- Industry Standards: Adhering to established standards for skate manufacturing ensures quality and safety.

7. Discuss the current trends in skateboard design and technology?

- Innovative Shapes: Non-traditional deck shapes for improved performance in specific disciplines.

- Advanced Materials: Composites and ultra-lightweight materials for increased strength and durability.

- Precision Manufacturing: CNC machines and 3D printing for accurate and consistent component production.

- Data-Driven Design: Using simulation and testing to optimize designs and improve performance.

- Sustainability: Incorporating eco-friendly materials and reducing waste in manufacturing.

8. Describe your understanding of the skateboarding community and its influence on skate design?

- Diverse Subcultures: Street, park, downhill, and other niche disciplines within skateboarding.

- Skater Input: Professional skateboarders and riders provide feedback on designs and test new products.

- Cultural Impact: Skateboarding influences fashion, art, and youth culture.

- Artistic Expression: Skateboards as a canvas for graphics and creativity.

- Community-Driven Innovation: Ideas and designs often emerge from the skateboarding community.

9. Explain how you stay up-to-date with the latest advancements in skate making technology and materials?

- Industry Events and Trade Shows: Attending exhibitions and conferences to connect with manufacturers and learn about new technologies.

- Online Research and Innovation: Monitoring industry news, websites, and forums for updates and advancements.

- Supplier Relationships: Establishing strong connections with suppliers to gain insights into new products and developments.

- Continuing Education and Workshops: Participating in workshops and training programs to enhance knowledge and skills.

- Networking and Collaboration: Connecting with other professionals in the skate industry to share ideas and explore innovations.

10. Describe your experience in working with different types of customers in a skate shop environment?

- Beginner Customers: Providing guidance and advice on selecting the right skateboard and gear.

- Experienced Skaters: Discussing technical details, recommending advanced products, and offering customized solutions.

- Retail Wholesale Customers: Maintaining relationships, fulfilling orders, and providing support on product inquiries.

- Online Customers: Answering questions, processing orders, and managing customer service through email and phone.

- Building Relationships: Establishing rapport with customers to understand their needs and provide personalized service.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Skate Maker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Skate Maker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Skate Maker is accountable for constructing and repairing ice skates. They work closely with customers to understand their requirements, design, and produce custom-made skates. Skate Makers need to have a deep understanding of skate anatomy, materials, and manufacturing processes to deliver high-quality products.

1. Skate Design and Production

Design and create ice skates based on customer specifications and requirements.

- Assess customer needs and preferences for skate type, fit, and performance level.

- Develop design concepts and technical drawings for skate components and assemblies.

- Select and source materials, including leather, metal alloys, and other components.

- Produce custom-made skates using specialized tools and techniques.

2. Repair and Maintenance

Inspect, diagnose, and repair ice skates to maintain their functionality and performance.

- Identify issues with skate blades, boots, and other components.

- Repair or replace damaged or worn parts using appropriate tools and materials.

- Sharpen and maintain skate blades to ensure optimal performance.

- Provide guidance to customers on proper skate care and maintenance.

3. Quality Control

Ensure that all skates meet established quality standards and specifications.

- Inspect finished skates for defects in materials, workmanship, and fit.

- Conduct performance tests to assess skate quality and functionality.

- Identify and address any issues or areas for improvement.

- Maintain accurate records of skate production and repair history.

4. Customer Service

Provide excellent customer service throughout the skate design, production, and repair process.

- Communicate effectively with customers to understand their needs and expectations.

- Explain technical details and provide guidance on skate selection and maintenance.

- Respond promptly to customer inquiries and resolve any issues.

- Build and maintain strong customer relationships.

Interview Tips

Preparing effectively for a Skate Maker interview can significantly increase your chances of success. Here are some valuable tips to help you ace the interview:

1. Research the Company and Position

Take the time to research the company you’re applying to and the specific Skate Maker position. This will demonstrate your interest and enthusiasm for the role.

- Visit the company website and social media pages to learn about their history, culture, and products.

- Read industry publications and articles to stay up-to-date on the latest trends and technologies in skate making.

- Prepare questions that show your understanding of the company and the position.

2. Highlight Your Skills and Experience

In your resume and during the interview, emphasize your relevant skills and experience in skate making. Quantify your accomplishments whenever possible.

- Describe your experience in designing, producing, and repairing ice skates.

- Provide specific examples of successful skate designs or repairs you have completed.

- Mention any certifications or training you have received in skate making or related fields.

3. Demonstrate Your Passion for Skate Making

Let the interviewer know that you are passionate about skate making and that you take pride in your work. Explain how your passion drives you to produce high-quality skates.

- Share any personal experiences or anecdotes that illustrate your love for skate making.

- Discuss your interest in different types of skates and how you enjoy learning about new materials and techniques.

- Explain how you stay updated on the latest advancements in skate making.

4. Prepare for Technical Questions

Be prepared to answer technical questions about skate making. This may include questions about skate design, materials, repair techniques, and quality control processes.

- Review the basics of skate anatomy and the different types of skates available.

- Familiarize yourself with common skate materials and their properties.

- Practice explaining how you would repair or maintain specific skate components.

5. Practice Your Communication Skills

Effective communication skills are essential for Skate Makers. Be confident and articulate in your responses during the interview.

- Practice answering questions clearly and concisely.

- Use examples and specific details to support your answers.

- Ask questions to show your engagement and interest in the conversation.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Skate Maker interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.