Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Shoe Stitcher position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

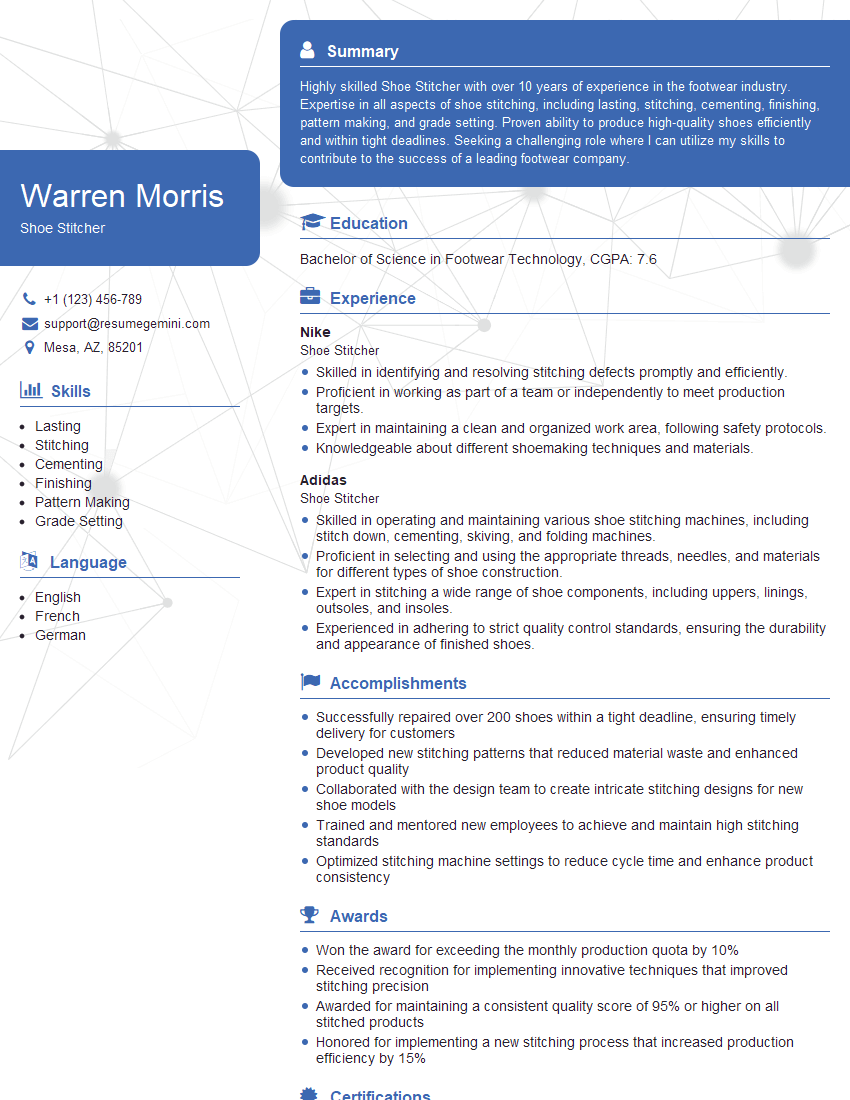

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Shoe Stitcher

1. What is the most common type of stitch used in shoemaking?

The most common type of stitch used in shoemaking is the lockstitch. This stitch is created by passing the thread through the material twice, creating a loop that is then locked in place by the next stitch. This stitch is strong and durable, making it ideal for use in shoes.

2. What are the different types of shoemaking machines?

Industrial Machines

- Single Needle Lockstitch Machine

- Double Needle Lockstitch Machine

Domestic Machines

- Straight Stitch Machine

- Zigzag Machine

3. What is the difference between a welt and a rand?

A welt is a strip of leather that is sewn around the edge of the shoe’s upper and insole. It provides support and stability to the shoe, and it also helps to keep the shoe waterproof. A rand is a strip of leather that is sewn around the outside of the welt. It provides additional support and protection to the shoe, and it can also be used to add decorative detail.

4. What is the purpose of a shoe last?

A shoe last is a form that is used to shape the shoe’s upper. It is made of wood or plastic, and it has a variety of different shapes and sizes to accommodate different types of shoes. The last is placed inside the shoe’s upper, and the upper is then sewn around it. This process helps to ensure that the shoe fits properly and that it has the correct shape.

5. What are the different types of shoe materials?

There are a wide variety of different shoe materials available, including leather, rubber, canvas, and synthetic materials. Each type of material has its own unique properties, and the choice of material will depend on the intended use of the shoe.

- Leather: Leather is a durable and breathable material that is often used in high-quality shoes. It is available in a variety of different colors and textures.

- Rubber: Rubber is a waterproof and flexible material that is often used in athletic shoes. It is also used in the soles of many different types of shoes.

- Canvas: Canvas is a strong and durable material that is often used in casual shoes. It is available in a variety of different colors and patterns.

- Synthetic materials: Synthetic materials are often used in athletic shoes and other types of shoes that require high performance. They are lightweight and durable, and they can be made to resemble a variety of different natural materials.

6. What are the different parts of a shoe?

- Upper: The upper is the part of the shoe that covers the foot. It is made of a variety of different materials, including leather, rubber, canvas, and synthetic materials.

- Sole: The sole is the part of the shoe that contacts the ground. It is made of a variety of different materials, including rubber, leather, and cork.

- Heel: The heel is the part of the shoe that raises the back of the foot. It can be made of a variety of different materials, including leather, rubber, and wood.

- Lining: The lining is the material that covers the inside of the shoe. It is usually made of a soft and breathable material, such as leather or fabric.

- Insole: The insole is the part of the shoe that supports the foot. It is usually made of a firm material, such as leather or cork.

- Outsole: The outsole is the part of the shoe that contacts the ground. It is usually made of a durable and wear-resistant material, such as rubber or leather.

7. What are the different types of shoe construction?

- Cemented construction: In cemented construction, the upper and sole of the shoe are glued together. This type of construction is lightweight and flexible, but it is not as durable as other types of construction.

- Blake stitch construction: In Blake stitch construction, the upper and sole of the shoe are sewn together using a single stitch. This type of construction is stronger and more durable than cemented construction, but it is also more expensive.

- Goodyear welt construction: In Goodyear welt construction, the upper and sole of the shoe are sewn together using a welt. A welt is a strip of leather that is sewn around the edge of the shoe’s upper and insole. This type of construction is the most durable and expensive type of shoe construction.

8. What are the different types of shoemaking tools?

- Awl: An awl is a sharp tool that is used to make holes in leather.

- Hammer: A hammer is used to drive nails and tacks.

- Knife: A knife is used to cut leather and other materials.

- Needle: A needle is used to sew leather and other materials.

- Pliers: Pliers are used to hold and bend wire and other materials.

- Screwdriver: A screwdriver is used to drive screws.

- Sewing machine: A sewing machine is used to sew leather and other materials.

- Soldering iron: A soldering iron is used to solder metal.

- Staple gun: A staple gun is used to staple leather and other materials.

- Tack hammer: A tack hammer is used to drive tacks.

- Wire cutters: Wire cutters are used to cut wire.

9. What are the different types of shoemaking techniques?

- Handsewing: Handsewing is a traditional shoemaking technique that involves sewing the shoe’s upper and sole together by hand. This technique is time-consuming and requires a high level of skill, but it produces a very durable and well-made shoe.

- Machine sewing: Machine sewing is a faster and more efficient shoemaking technique that involves sewing the shoe’s upper and sole together using a sewing machine. This technique is less labor-intensive than handsewing, but it can produce a less durable shoe.

- Cementing: Cementing is a shoemaking technique that involves gluing the shoe’s upper and sole together. This technique is quick and easy, but it produces a less durable shoe than handsewing or machine sewing.

10. What are the different types of shoemaking defects?

- Stitching defects: Stitching defects can occur when the stitches are not sewn correctly. This can result in the shoe being weak or uncomfortable.

- Material defects: Material defects can occur when the shoe is made from defective materials. This can result in the shoe being weak or uncomfortable.

- Construction defects: Construction defects can occur when the shoe is not constructed correctly. This can result in the shoe being weak or uncomfortable.

- Design defects: Design defects can occur when the shoe is not designed correctly. This can result in the shoe being uncomfortable or unsafe.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Shoe Stitcher.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Shoe Stitcher‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Shoe Stitchers are responsible for the intricate task of stitching together the various components of shoes, ensuring their durability and aesthetic appeal. Their work demands precision, attention to detail, and a deep understanding of different stitching techniques.

1. Footwear Assembly

Shoe Stitchers play a crucial role in the assembly of footwear by stitching together its constituent parts, including the upper (the outer material covering the foot), the sole, and the lining. They expertly join these components using specialized sewing machines, ensuring a secure and long-lasting bond.

2. Sole Stitching

Attaching the sole to the upper is a critical step in shoe construction. Shoe Stitchers meticulously stitch the sole to the upper, ensuring it is firmly and evenly attached. They use specialized techniques, such as the Blake stitch or the Goodyear welt, to create durable and aesthetically pleasing seams.

3. Reinforcement Stitching

To enhance the longevity of footwear, Shoe Stitchers reinforce key areas of the shoe, such as the toe box, heel counter, and lace stays. They employ specific stitching techniques to strengthen these areas, preventing premature wear and tear.

4. Decorative Stitching

In addition to functional stitching, Shoe Stitchers also perform decorative stitching to enhance the aesthetic appeal of footwear. They stitch intricate patterns, logos, and embellishments onto the shoes, adding a touch of style and personalization.

Interview Tips

Interview preparation is paramount for candidates seeking to excel in their Shoe Stitcher interviews. By following these tips and demonstrating a deep understanding of the role’s responsibilities, candidates can confidently showcase their skills and increase their chances of success.

1. Research the Company and Position

Thoroughly researching the company and the specific Shoe Stitcher position is essential. Candidates should visit the company website to gain insights into the company’s culture, values, and products. They should also carefully review the job description to fully understand the expectations of the role.

2. Practice Answering Common Interview Questions

Preparing for common interview questions is crucial for success. Candidates should anticipate questions about their experience, technical skills, and problem-solving abilities. It is advisable to practice answering these questions out loud to gain confidence and fluency.

3. Showcase Your Technical Expertise

Emphasizing their technical expertise in shoe stitching is vital for candidates. They should highlight their proficiency in using different sewing machines, stitching techniques, and materials. Providing specific examples of complex stitching projects they have completed can demonstrate their skills effectively.

4. Emphasize Quality and Attention to Detail

Shoe Stitchers must possess an unwavering commitment to quality and attention to detail. Candidates should emphasize their meticulous approach to their work, ensuring that every stitch meets the highest standards. They can provide examples of how their attention to detail has contributed to the durability and aesthetics of footwear they have stitched.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Shoe Stitcher role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.