Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Trimming Cutter position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

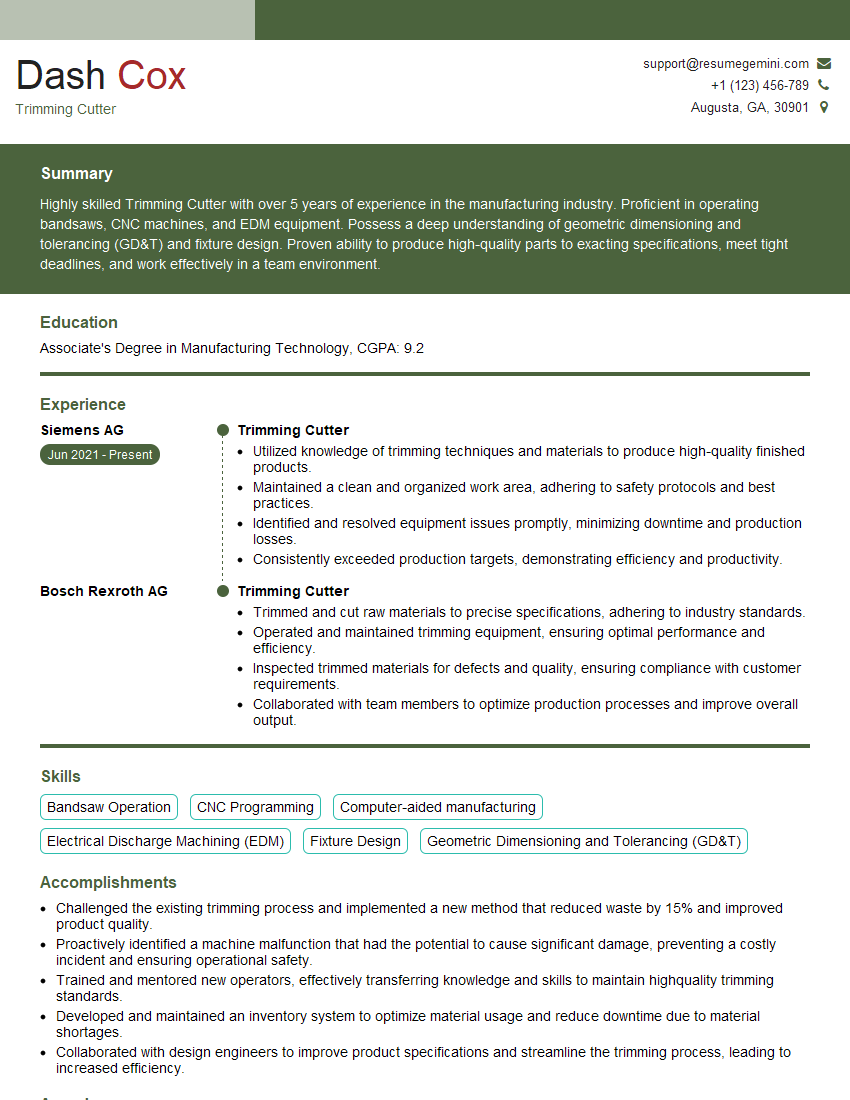

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Trimming Cutter

1. Describe the process of tool alignment in a Trimming Cutter?

In tool alignment, the Trimming Cutter is meticulously positioned to ensure precise cutting operations. Here’s the step-by-step process:

- Establish a Reference Point: Determine a fixed reference point on the machine or workpiece to align the Trimming Cutter.

- Mount the Trimming Cutter: Securely mount the Trimming Cutter onto the machine spindle or tool holder.

- Use Alignment Tools: Employ precision alignment tools such as dial indicators or laser alignment systems to measure and adjust the Trimming Cutter’s position relative to the reference point.

- Adjust Cutter Height: Set the Trimming Cutter’s height relative to the workpiece surface using shims or adjustable tool holders.

- Fine-tune Position: Make minute adjustments to the Trimming Cutter’s position using the machine’s controls or manual micrometers until the desired alignment is achieved.

- Verify Alignment: Conduct test cuts or use measurement tools to verify the accuracy of the alignment and ensure precise cutting.

2. Explain the different types of Trimming Cutters and their applications?

Types of Trimming Cutters

- Shear Cut Trimming Cutters: Designed for clean and precise cutting of thin materials, such as paper, plastic films, and non-ferrous metals.

- Rotary Trimming Cutters: Feature rotating blades for continuous trimming of materials, commonly used in high-volume production environments.

- Oscillating Trimming Cutters: Utilize a reciprocating motion to trim materials, suitable for intricate cuts and delicate materials.

- Guillotine Trimming Cutters: Employ a sharp blade that descends vertically to cut materials, ideal for heavy-duty applications and thick materials.

Applications

- Packaging Industry: Trimming excess material from packaging materials, such as cardboard, paperboard, and plastic films.

- Printing Industry: Cutting and trimming printed materials, including books, magazines, and brochures.

- Textile Industry: Trimming excess fabric from textiles and garments.

- Metalworking Industry: Removing burrs and excess material from metal parts.

3. What factors influence the selection of a Trimming Cutter for a specific application?

- Material Properties: Hardness, thickness, and type of material being cut.

- Cutting Precision: Required accuracy and tolerance for the trimming operation.

- Production Volume: Number of parts or pieces to be trimmed.

- Speed Requirements: Desired cutting speed and cycle time.

- Machine Compatibility: Compatibility with the available machine spindle or tool holder.

- Cost and Availability: Budget and availability of the Trimming Cutter.

4. Describe the safety precautions to be observed when operating a Trimming Cutter?

- Wear Proper PPE: Use safety glasses, earplugs, and gloves to protect from flying debris and noise.

- Inspect Equipment: Check the Trimming Cutter for any damage or loose parts before use.

- Securely Mount: Ensure the Trimming Cutter is securely mounted to the machine.

- Keep Clear of Moving Parts: Maintain a safe distance from rotating blades and moving parts.

- Use Appropriate Guards: Utilize safety guards to prevent accidental contact with sharp edges.

- Follow Instructions: Adhere to the manufacturer’s instructions for safe operation.

5. How do you troubleshoot common issues encountered when using a Trimming Cutter?

- Poor Cut Quality: Check blade sharpness, alignment, and material suitability.

- Excessive Noise or Vibration: Inspect for loose components, misalignment, or dull blades.

- Trimming Cutter Sticking: Check for material buildup, lubrication, or worn parts.

- Blade Breakage: Inspect for blade damage, improper mounting, or excessive cutting forces.

- Machine Malfunctions: Refer to the machine’s user manual and consult with a qualified technician.

6. How do you maintain a Trimming Cutter to ensure optimal performance?

- Regular Cleaning: Remove debris and buildup from the Trimming Cutter.

- Blade Sharpening: Sharpen or replace dull blades to maintain cutting efficiency.

- Lubrication: Apply lubricant to moving parts as per manufacturer’s recommendations.

- Alignment Checks: Periodically check and adjust the alignment to ensure precision.

- Preventative Maintenance: Conduct regular inspections and replace worn or damaged parts promptly.

7. Explain the advantages of using a Trimming Cutter over other cutting methods?

- Precision Cutting: Trimming Cutters provide highly precise cuts with minimal material waste.

- Speed and Efficiency: Automated Trimming Cutters offer faster cutting speeds and improved productivity.

- Versatility: Trimming Cutters can handle a wide range of materials and applications.

- Reduced Operator Fatigue: Automated Trimming Cutters eliminate manual labor, reducing operator fatigue.

- Improved Safety: Safety guards and automated operation minimize the risk of injuries.

8. Describe the latest advancements in Trimming Cutter technology?

- Laser-Guided Trimming: High-precision trimming using laser technology for intricate cuts.

- Automated Vision Systems: Integration of vision systems for accurate part identification and alignment.

- IoT Connectivity: Monitoring and control of Trimming Cutters remotely via IoT devices.

- Advanced Cutting Materials: Development of new cutting materials for improved durability and cutting performance.

- Sustainable Solutions: Eco-friendly Trimming Cutters with reduced energy consumption and waste generation.

9. What are the key factors to consider when designing a Trimming Cutter for a specific application?

- Cutting Force Requirements: Determine the cutting forces necessary for the material and application.

- Blade Geometry: Design the blade profile based on the material properties and desired cut quality.

- Spindle Compatibility: Ensure compatibility with the available machine spindle or tool holder.

- Safety Features: Incorporate appropriate safety guards and operating mechanisms.

- Durability and Maintenance: Optimize the Trimming Cutter for durability and ease of maintenance.

10. How do you stay updated on the latest trends and developments in Trimming Cutter technology?

- Industry Trade Shows: Attend exhibitions and conferences showcasing the latest Trimming Cutter technologies.

- Technical Publications: Read industry journals and articles to keep abreast of advancements.

- Manufacturer Websites: Visit websites of reputable Trimming Cutter manufacturers for product updates and technical information.

- Online Forums: Engage with online communities and forums dedicated to Trimming Cutters.

- Networking: Connect with industry professionals and attend webinars or seminars on Trimming Cutter technology.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Trimming Cutter.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Trimming Cutter‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Trimming Cutters are highly skilled individuals responsible for ensuring the precision and accuracy of cutting operations in various industries. Their primary duties involve using specialized cutting tools and equipment to shape and trim materials according to specifications.

1. Cutting and Shaping Materials

Trimming Cutters expertly operate cutting machines to trim and shape a wide range of materials, including textiles, leather, plastic, and metal. They adhere to precise measurements and specifications to achieve the desired dimensions and contours.

- Precisely cut and trim materials using specialized cutting tools and machinery.

- Follow cutting patterns, templates, or technical drawings to ensure accuracy.

2. Machine Operation and Maintenance

Trimming Cutters are proficient in operating various cutting machines, such as band saws, shearers, and guillotines. They also perform regular maintenance and cleaning tasks to ensure optimal performance and prevent breakdowns.

- Operate and maintain cutting machines, ensuring their efficient and safe operation.

- Perform routine maintenance tasks, such as cleaning, lubrication, and minor repairs.

3. Quality Inspection and Control

Trimming Cutters meticulously inspect finished products to ensure they meet quality standards and specifications. They identify and correct any defects or imperfections to maintain high-quality output.

- Inspect finished products for accuracy, precision, and conformity to specifications.

- Identify and rectify any deviations from established quality standards.

4. Safety and Compliance

Trimming Cutters prioritize safety in the workplace. They adhere to established safety protocols, wear appropriate personal protective equipment, and maintain a clean and organized work environment.

- Follow established safety guidelines and regulations.

- Wear appropriate safety gear, including gloves, eye protection, and hearing protection.

Interview Tips

Preparing for a Trimming Cutter interview requires careful preparation and a thorough understanding of the role’s responsibilities. Here are some effective tips to help you ace the interview:

1. Research the Company and Position

Before the interview, take the time to research the company, their industry, and the specific Trimming Cutter position you are applying for. This will demonstrate your interest and enthusiasm for the role and enable you to ask informed questions.

- Visit the company’s website and social media pages.

- Read industry-related publications and articles.

2. Practice Your Answers

Prepare for common interview questions by rehearsing your responses. Focus on highlighting your relevant skills, experience, and qualifications. Consider using the STAR method (Situation, Task, Action, Result) to structure your answers and provide concrete examples.

- Identify common interview questions and prepare your responses.

- Use the STAR method to provide specific and relevant examples.

3. Emphasize Safety and Quality

Trimming Cutters are responsible for ensuring safety and maintaining high-quality output. During the interview, emphasize your commitment to safety protocols and your attention to detail. Share examples of how you have prioritized safety and achieved quality results in previous roles.

- Discuss your safety practices and adherence to regulations.

- Provide examples of how you have maintained high-quality standards in your work.

4. Show Your Enthusiasm

Conveying your passion for the role and the industry is crucial. Throughout the interview, demonstrate your interest in the Trimming Cutter position and your eagerness to contribute to the company’s success.

- Express your interest in the role and the company.

- Share your knowledge of the industry and current trends.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Trimming Cutter interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.