Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Binding Dyer position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

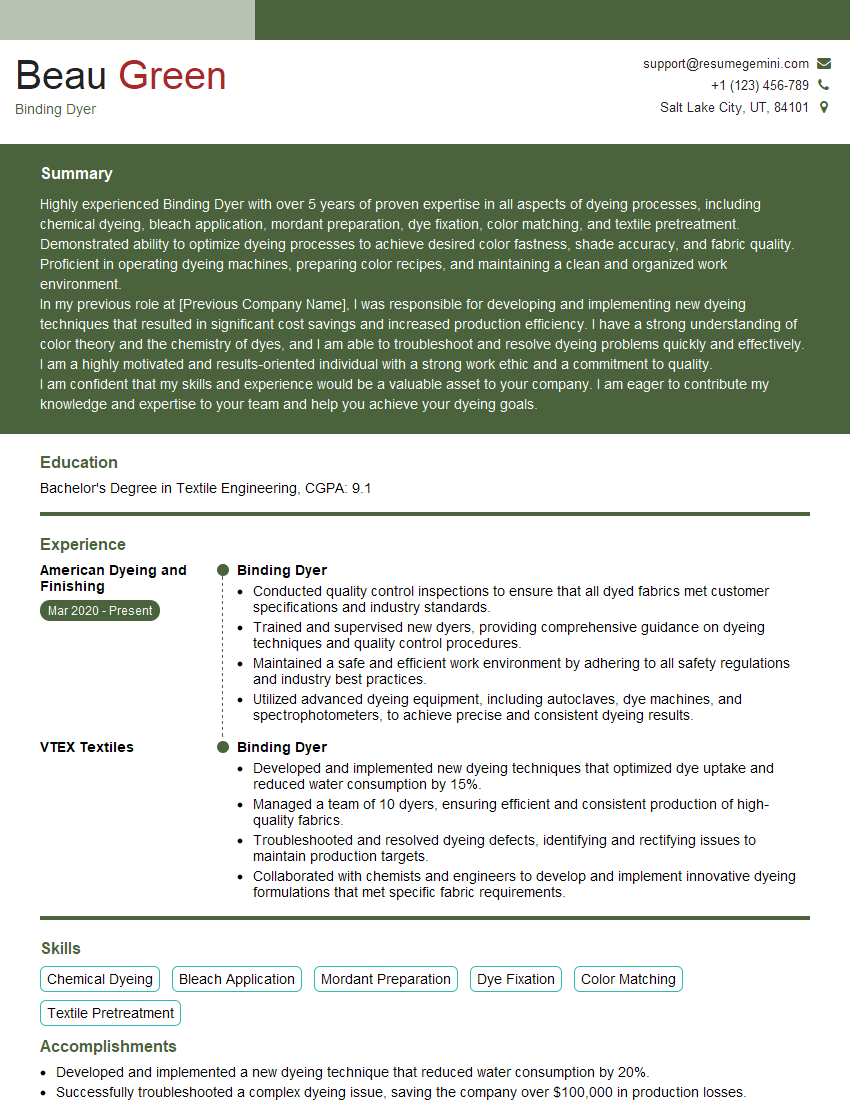

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Binding Dyer

1. What is the process of binding dyes to fibers?

The process of binding dyes to fibers involves several steps, including:

- Preparation: Fibers are cleaned and treated to remove impurities and improve dye uptake.

- Dyeing: Dyes are dissolved in water or a solvent and applied to the fibers using various methods, such as immersion, padding, or spraying.

- Fixing: The dye is fixed onto the fibers using heat, chemicals, or a combination of both. This step ensures the dye remains bound and resists fading or bleeding.

- Washing and Drying: The dyed fibers are washed to remove excess dye and dried to complete the process.

2. What are the different classes of dyes and give an example of each?

Natural Dyes

- Extract from plants (e.g., indigo, madder root)

- Derivatives from animals (e.g., cochineal, Tyrian purple)

Synthetic Dyes

- Azo dyes (e.g., Direct Red 81, Mordant Black 17)

- Anthraquinone dyes (e.g., Alizarin, Vat Blue 4)

- Triphenylmethane dyes (e.g., Crystal Violet, Malachite Green)

Mordant Dyes

- Bind to fibers using a mordant (e.g., alum, iron salts)

- Examples: Alizarin, Cochineal

3. What factors affect the colorfastness of dyes?

Factors that affect the colorfastness of dyes include:

- Dye Type: Different dyes have varying degrees of resistance to fading, bleeding, and other factors.

- Fiber Type: The type of fiber being dyed influences the dye’s ability to bind and resist fading.

- Dyeing Method: The application method affects the depth of penetration and the overall colorfastness.

- Fixing and Aftertreatment: Proper fixing and aftertreatment processes, such as heat treatment or chemical baths, enhance dye retention.

- Environmental Factors: Exposure to light, moisture, and chemicals can affect dye stability and colorfastness.

4. What are the different dye bath additives and their functions?

Dye bath additives are chemicals used in the dyeing process to improve the properties of the dyed materials. Common additives include:

- Leveling Agents: Promote even dye distribution and prevent uneven dyeing.

- Retarders: Slow down the dyeing process, allowing for greater dye penetration and depth.

- Modifiers: Alter the shade or intensity of the dye.

- Wetting Agents: Improve the penetration of dyes into the fibers by reducing surface tension.

- Carriers: Help dissolve and transport dyes that are not soluble in water.

5. What is the role of pH in the dyeing process?

pH plays a crucial role in the dyeing process by affecting:

- Dye Solubility: The solubility of some dyes depends on the pH of the dye bath.

- Fiber Affinity: The attraction between the dye and the fiber is influenced by the pH.

- Dye Fixation: The rate and effectiveness of dye fixation can vary with pH.

- Color Shade: In some cases, the pH can alter the shade of the dyed material.

6. Describe the different methods for applying dyes to fibers.

Dyeing methods include:

- Immersion Dyeing: Submerging fibers in a dye bath.

- Padding Dyeing: Passing fibers through a pad saturated with dye.

- Spray Dyeing: Applying dye to fibers using a spray gun.

- Screen Printing: Using a stencil to apply dye to specific areas of the fabric.

- Inkjet Printing: Digitally printing dyes onto fibers.

7. What are the advantages and disadvantages of using natural dyes?

Advantages:

- Eco-friendly and sustainable.

- Often have unique and vibrant colors.

- Can provide a rustic or antique aesthetic.

Disadvantages:

- Can be more expensive than synthetic dyes.

- Colorfastness may not be as high as synthetic dyes.

- Limited color range compared to synthetic dyes.

8. What is the importance of testing and evaluating dyes before use?

Testing and evaluating dyes before use is crucial for several reasons:

- Colorfastness Assessment: Ensuring the dye meets the desired colorfastness requirements for the intended application.

- Shade Verification: Confirming that the dye produces the expected shade and meets color specifications.

- Compatibility Testing: Evaluating the compatibility of the dye with the chosen fiber and other chemicals used in the dyeing process.

- Optimization of Dyeing Parameters: Determining the optimal dyeing conditions, such as temperature, pH, and dye concentration, to achieve the desired results.

9. Describe the principles of color theory as applied to dyeing.

Color theory provides guidelines for understanding and manipulating colors in dyeing:

- Color Wheel: The color wheel is a visual representation of the relationships between colors.

- Primary Colors: Red, yellow, and blue are the primary colors that cannot be created by mixing other colors.

- Secondary Colors: Orange, green, and violet are secondary colors created by mixing primary colors.

- Complementary Colors: Colors that are opposite each other on the color wheel, such as red and green, can create high contrast and visual interest when used together.

10. What are the potential hazards associated with the handling and use of dyes?

Potential hazards associated with dyes include:

- Toxicity: Some dyes can be toxic if ingested, inhaled, or absorbed through the skin.

- Allergic Reactions: Certain dyes can cause allergic reactions, such as skin irritation or respiratory problems.

- Environmental Impact: Dye waste can pollute water sources if not properly disposed of.

- Protective Measures: Handling dyes requires appropriate safety measures, such as wearing protective clothing, gloves, and respirators.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Binding Dyer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Binding Dyer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Binding Dyers are responsible for dyeing and coloring bindings, yarns, and other materials used in the production of books, stationery, and other products. Their key responsibilities include:

1. Dyeing and coloring bindings

Binding Dyers use a variety of dyes and coloring agents to dye and color bindings, yarns, and other materials. They must be able to mix and apply dyes and coloring agents accurately and consistently to achieve the desired results.

- Mix and apply dyes and coloring agents to bindings, yarns, and other materials.

- Use a variety of dyeing and coloring techniques to achieve the desired results.

- Ensure that the dyes and coloring agents are applied evenly and consistently.

2. Testing and inspecting dyed materials

Binding Dyers must test and inspect dyed materials to ensure that they meet the required standards. They must be able to identify and correct any defects in the dyeing process.

- Test and inspect dyed materials to ensure that they meet the required standards.

- Identify and correct any defects in the dyeing process.

- Maintain a record of all testing and inspection results.

3. Maintaining equipment

Binding Dyers are responsible for maintaining the equipment used in the dyeing process. They must be able to troubleshoot and repair any problems with the equipment.

- Maintain the equipment used in the dyeing process.

- Troubleshoot and repair any problems with the equipment.

- Ensure that the equipment is operating safely and efficiently.

4. Following safety procedures

Binding Dyers must follow all safety procedures when working with dyes and coloring agents. They must be aware of the potential hazards of these materials and take steps to protect themselves and others.

- Follow all safety procedures when working with dyes and coloring agents.

- Be aware of the potential hazards of these materials.

- Take steps to protect themselves and others from exposure to these materials.

Interview Tips

To prepare for an interview for a Binding Dyer position, it is important to:

1. Research the company and the position

Before the interview, research the company and the specific Binding Dyer position you are applying for. This will help you to understand the company’s culture and the specific requirements of the position.

- Visit the company’s website to learn about their history, mission, and values.

- Read the job posting carefully to understand the specific requirements of the position.

- Look for any news articles or reviews about the company to get a sense of their reputation.

2. Practice answering common interview questions

There are a number of common interview questions that you may be asked in an interview for a Binding Dyer position. It is important to practice answering these questions so that you can do so confidently and clearly.

- Tell me about yourself.

- Why are you interested in this position?

- What are your strengths and weaknesses?

- What is your experience with dyeing and coloring materials?

- How do you ensure that the dyes and coloring agents are applied evenly and consistently?

3. Prepare questions to ask the interviewer

At the end of the interview, you will likely be given an opportunity to ask the interviewer questions. Prepare a few thoughtful questions to ask, such as:

- What are the biggest challenges facing the company right now?

- What are the opportunities for growth and advancement within the company?

- What is the company’s culture like?

4. Dress professionally and arrive on time

First impressions matter, so dress professionally and arrive on time for your interview. This will show the interviewer that you are serious about the position and that you respect their time.

- Dress in business attire.

- Be on time for your interview.

- Be polite and respectful to everyone you meet.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Binding Dyer interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!