Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Bobbin Winder position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

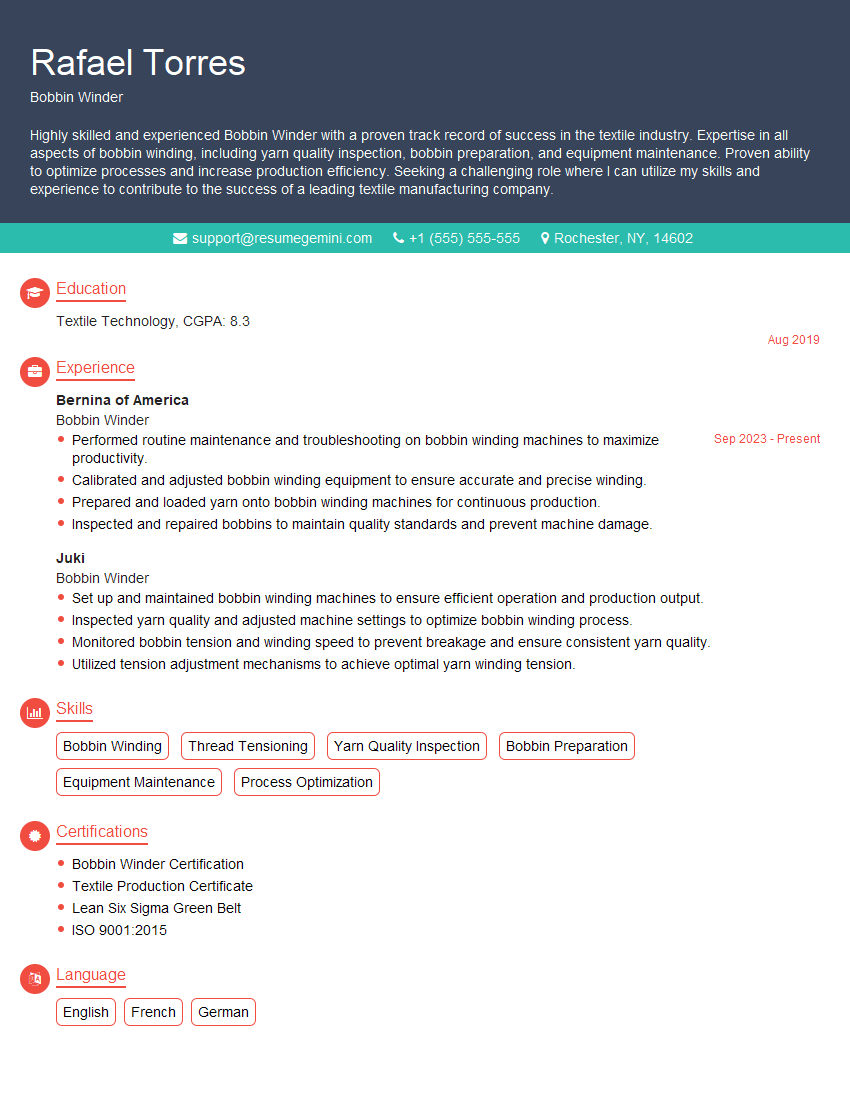

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Bobbin Winder

1. Please explain the process of bobbin winding?

The process of bobbin winding involves several steps:

- Preparing the bobbin: Inserting an empty bobbin into the winding machine and securing it in place.

- Selecting yarn: Choosing the appropriate yarn for the winding process based on the desired properties and specifications.

- Threading the machine: Guiding the yarn through the tensioning devices and onto the bobbin holder.

- Adjusting tension: Setting the tension controls to ensure the yarn is wound evenly and securely onto the bobbin.

- Winding: Activating the winding machine to rotate the bobbin and wrap the yarn around it, forming layers.

- Doffing the bobbin: Once the bobbin is fully wound, removing it from the machine.

2. What factors affect the quality of bobbin winding?

Yarn characteristics:

- Yarn tension

- Yarn thickness

- Yarn elasticity

Machine settings:

- Winding speed

- Tension control

- Bobbin size

Environmental conditions:

- Temperature

- Humidity

3. How do you ensure the consistency of wound bobbins?

- Regular machine calibration: Maintaining and calibrating the winding machine to ensure accurate and consistent performance.

- Yarn quality control: Inspecting and testing the yarn before winding to minimize defects and ensure consistency.

- Monitoring winding parameters: Continuously monitoring winding speed, tension, and other parameters to identify and address issues promptly.

- Bobbin inspection: Conducting thorough visual and tactile inspections of wound bobbins to identify any irregularities or defects.

4. What are the different types of bobbin winding machines and their applications?

- Semi-automatic bobbin winders: Suitable for small-scale production, require manual loading and unloading of bobbins.

- Automatic bobbin winders: High-speed machines designed for large-scale production, feature automatic bobbin loading and unloading.

- Precision bobbin winders: Used for winding delicate or high-value yarns, provide precise control over winding tension and speed.

- Traverse bobbin winders: Create specific winding patterns on the bobbin for special applications, such as cross-wound bobbins for embroidery.

5. What is the importance of bobbin tension in the winding process?

- Yarn breakage prevention: Proper tension prevents the yarn from breaking during winding, ensuring bobbin integrity.

- Even winding: Controlled tension allows for even and consistent winding, avoiding loose or tight spots on the bobbin.

- Bobbin stability: Adequate tension helps maintain the shape and stability of the wound bobbin, minimizing tangles or unwinding.

- Yarn quality: Maintaining appropriate tension preserves yarn properties, preventing damage or alteration.

6. How do you troubleshoot common bobbin winding issues?

- Uneven winding: Adjust tension settings, check yarn tension devices, or calibrate the winding machine.

- Bobbin tangles: Inspect the yarn path for obstructions, clean the machine, or adjust the winding speed.

- Yarn breakage: Check the yarn quality, adjust tension controls, or inspect the machine for damage.

- Loose winding: Increase tension, check bobbin holder alignment, or tighten the bobbin.

7. What are the safety precautions to consider when operating bobbin winding machines?

- Wear appropriate PPE: Safety glasses, gloves, and hearing protection.

- Keep moving parts guarded: Ensure all machine guards are in place and functional.

- Avoid loose clothing: Prevent entanglement in moving parts.

- Maintain a clean work area: Clear away debris and yarn scraps to minimize tripping hazards.

- Report any issues promptly: Inform supervisors of any machine malfunctions or safety concerns.

8. How do you maintain and calibrate bobbin winding machines?

- Regular cleaning: Remove dust, lint, and yarn scraps from the machine to prevent malfunctions.

- Lubrication: Follow manufacturer’s instructions for lubrication to ensure smooth operation.

- Tension calibration: Use a tension gauge to calibrate the tension controls accurately.

- Speed adjustment: Adjust winding speed to optimize performance and yarn quality.

- Software updates: Regularly update software to address bugs and improve machine performance.

9. What is your approach to minimizing production downtime during bobbin winding operations?

- Preventive maintenance: Regular maintenance helps prevent unexpected breakdowns.

- Spare parts inventory: Maintain a stock of essential spare parts to address issues promptly.

- Trained operators: Ensure operators are well-trained to identify and resolve minor problems.

- Process optimization: Continuously review and improve winding processes to minimize downtime.

10. How do you ensure compliance with quality standards in bobbin winding?

- Establish clear standards: Define acceptable quality parameters and winding specifications.

- Regular inspections: Conduct regular inspections of wound bobbins to identify any deviations from standards.

- Process documentation: Maintain records of winding parameters, machine settings, and inspection results for traceability.

- Statistical quality control: Use statistical methods to monitor and control winding quality, identifying trends and areas for improvement.

- Continuous improvement: Implement ongoing initiatives to enhance quality and meet evolving industry standards.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Bobbin Winder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Bobbin Winder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Job Responsibilities

A Bobbin Winder is a textile manufacturing professional responsible for preparing bobbins for textile machinery. Bobbin winders operate machinery that winds yarn onto bobbins. The wound bobbins are used to supply yarn to spinning, twisting, weaving, and knitting machines. The key responsibilities of a Bobbin Winder include:

1. Machine Operation

Bobbin winders operate machines that wind yarn onto bobbins. They ensure the proper functioning of the machines and make necessary adjustments to maintain optimal winding tension and speed.

- Monitor winding machines to ensure smooth operation and identify any issues.

- Adjust machine settings to optimize yarn tension, speed, and bobbin size.

- Maintain and clean winding machines to ensure their efficiency and prevent breakdowns.

2. Bobbin Preparation

Bobbin winders prepare bobbins by selecting the appropriate yarn and ensuring the bobbin is properly loaded onto the winding machine. They also inspect bobbins for defects and ensure they meet quality standards.

- Select the correct type and count of yarn for winding.

- Inspect bobbins for any defects or damage before winding.

- Load bobbins onto the winding machine and secure them properly.

3. Yarn Handling

Bobbin winders handle yarn carefully to prevent tangles, breaks, or other damage. They ensure the yarn is properly tensioned and guided onto the bobbin during the winding process.

- Guide yarn onto bobbins to ensure even winding and prevent tangles.

- Control yarn tension to achieve the desired winding density and quality.

- Inspect yarn for defects or breaks and take corrective actions as needed.

4. Quality Control

Bobbin winders are responsible for ensuring the quality of the wound bobbins. They inspect bobbins for defects, such as uneven winding, loose yarn, or contamination. They also maintain records of production and quality checks.

- Inspect wound bobbins for defects and ensure they meet quality standards.

- Maintain records of production and quality checks to track performance and identify areas for improvement.

- Report any quality issues or machine malfunctions to supervisors.

Interview Preparation Tips

To prepare for a Bobbin Winder interview, it is essential to understand the job responsibilities and demonstrate your skills and experience. Here are some tips to help you ace your interview:

1. Research the Company and Position

Research the company you’re applying to, including their products, services, and industry reputation. This will help you understand their business and how your skills and experience align with their needs. Also, review the job description thoroughly to identify the specific responsibilities and qualifications.

- Visit the company’s website and social media pages.

- Read industry news and articles to stay up-to-date on the latest trends.

- Analyze the job description to understand the company’s expectations.

2. Showcase Relevant Skills and Experience

Highlight your skills and experience that are relevant to the Bobbin Winder position. Focus on your ability to operate winding machines, handle yarn, and maintain quality standards. Provide specific examples of your work to demonstrate your proficiency.

- Quantify your accomplishments whenever possible, using specific metrics to demonstrate your impact.

- Prepare examples of how you have handled challenging situations or solved problems related to bobbin winding.

- Highlight your attention to detail and commitment to quality.

3. Practice Common Interview Questions

Anticipate common interview questions and prepare your answers in advance. Practice delivering your responses clearly and concisely, highlighting your qualifications and enthusiasm for the position.

- Prepare answers to questions about your experience, skills, and motivations.

- Practice answering behavioral interview questions using the STAR method (Situation, Task, Action, Result).

- Consider asking thoughtful questions at the end of the interview to demonstrate your interest and engagement.

4. Dress Professionally and Arrive on Time

First impressions matter, so dress professionally and arrive on time for your interview. This shows respect for the interviewer and the company. Maintain eye contact, speak clearly, and be confident in your abilities.

- Choose attire that is appropriate for a manufacturing environment.

- Arrive at least 15 minutes early to allow time for parking and any unforeseen delays.

- Bring a portfolio or examples of your work if relevant.

5. Be Enthusiastic and Ask Questions

Convey your enthusiasm for the Bobbin Winder position and the textile industry. Ask thoughtful questions to show your interest and engagement. This will help you stand out from other candidates.

- Express your passion for textiles and your desire to contribute to the company’s success.

- Ask questions about the company’s growth plans, industry trends, or specific challenges related to bobbin winding.

- Show that you are eager to learn and grow within the organization.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Bobbin Winder interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.