Feeling lost in a sea of interview questions? Landed that dream interview for Channel Cementer but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Channel Cementer interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

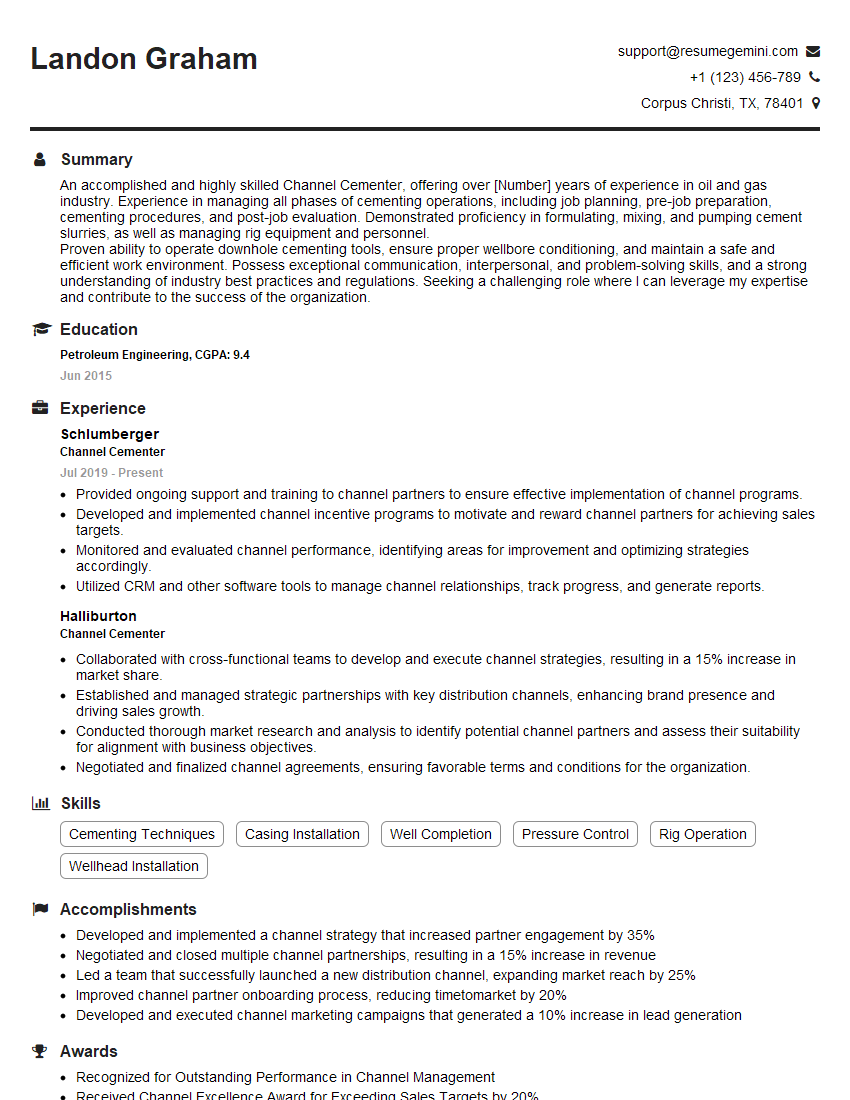

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Channel Cementer

1. What are the different types of channel cements available?

- I am familiar with a range of channel cements, including:

- Hydrostatic Channel Cement: – Used for sealing cable channels against water penetration. – Provides excellent adhesion to various substrates.

- Flame Retardant Channel Cement: – Designed for fire safety applications in cable trays. – Delivers high-temperature resistance and flame retardancy.

- Low-VOC Channel Cement: – Environmentally friendly option with low levels of volatile organic compounds (VOCs). – Complies with regulations for indoor use.

- Corrosion-Resistant Channel Cement: – Provides protection against corrosion in harsh environments. – Ideal for use in coastal and industrial areas.

2. What factors should be considered when selecting a channel cement?

Durability and Service Life:

- Evaluate the expected lifespan and performance requirements.

- Consider the environmental conditions in which the cement will be used.

Adhesion Characteristics:

- Ensure the cement will adhere effectively to the cable channel and the surrounding substrate.

- Consider the surface roughness and porosity of the materials involved.

Application Method and Curing Time:

- Choose a cement that is compatible with the desired application method (e.g., trowel, gun).

- Consider the curing time required and any limitations it may impose.

Regulatory Compliance:

- Verify that the chosen cement meets industry standards and complies with relevant regulations.

- Consider factors such as fire safety, environmental impact, and worker safety.

3. What are the key steps in applying channel cement?

- Surface Preparation: Clean and prepare both the cable channel and the surrounding substrate to ensure proper adhesion.

- Application: Apply the channel cement according to the manufacturer’s instructions, using an appropriate tool.

- Positioning: Securely position the cable channel in place and press it firmly into the cement.

- Smoothing: Use a trowel or sealant gun to smooth the cement around the edges of the channel.

- Curing: Allow the cement to cure for the recommended time to achieve the desired bonding strength.

4. How do you ensure the proper bonding of channel cement?

- Surface Preparation: Proper surface preparation, including cleaning and removing any contaminants, is essential for strong adhesion.

- Correct Application: Follow the manufacturer’s instructions for the correct application technique and application rate.

- Even Pressure: Apply even pressure when installing the channel to ensure uniform bonding throughout.

- Curing Time: Allow the cement to cure completely before applying any load or stress to the joint.

5. What are some common troubleshooting tips for channel cement?

- Poor Adhesion: Ensure that the surfaces are clean and free of contaminants, and that the correct cement type is used.

- Leakage: Check for gaps or voids in the cement application, and reapply as necessary.

- Curing Problems: Verify that the curing time is sufficient and that there are no environmental factors interfering with the process.

- Incorrect Application: Follow the manufacturer’s instructions carefully to avoid over- or under-application, which can affect performance.

6. What safety precautions should be taken when working with channel cement?

- Read and Understand MSDS: Review the Material Safety Data Sheet (MSDS) to understand the potential hazards and safe handling practices.

- Wear PPE: Use appropriate personal protective equipment (PPE), including gloves, safety glasses, and respirators as required.

- Proper Ventilation: Ensure adequate ventilation in the work area to minimize exposure to fumes or dust.

- Avoid Skin and Eye Contact: Handle the cement carefully to prevent skin or eye contact and wash thoroughly if exposure occurs.

7. How do you handle the disposal of channel cement?

- Follow Local Regulations: Adhere to local regulations and guidelines for the disposal of construction materials.

- Minimize Waste: Use the cement efficiently and dispose of any excess responsibly.

- Reuse and Recycle: If possible, explore options for reusing or recycling the cement or its containers.

- Dispose at Authorized Sites: Dispose of the cement at authorized disposal facilities or designated landfills.

8. What are the latest trends in channel cement technology?

- Low-VOC and Environmentally Friendly: Growing demand for channel cements that minimize VOC emissions and environmental impact.

- Faster Curing: Cements with accelerated curing times to reduce project timelines and improve efficiency.

- Multi-Purpose Applications: Development of versatile channel cements suitable for a wider range of substrates and applications.

- Improved Durability: Focus on developing durable channel cements with increased resistance to harsh conditions and aging effects.

9. How do you stay updated on the latest developments in channel cement?

- Industry Publications and Journals: Regular reading of industry-specific magazines and journals.

- Conferences and Trade Shows: Attend relevant events to network with professionals and gain insights on new products and technologies.

- Manufacturer Websites: Visit the websites of leading channel cement manufacturers for product information and updates.

- Online Resources: Utilize industry forums, articles, and online databases for knowledge sharing and continuing education.

10. How would you manage a situation where the client requests a channel cement that is not suitable for the project’s requirements?

- Communicate Clearly: Explain the reasons why the requested cement is not appropriate for the project, providing technical evidence and industry standards.

- Suggest Alternatives: Offer viable alternatives that meet the project’s specific needs, discussing their advantages and disadvantages.

- Document the Process: Keep a record of all communications and decisions made, including the client’s request, your recommendations, and the final solution.

- Maintain Professionalism: Handle the situation professionally and courteously, ensuring that the client understands the rationale behind your recommendations.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Channel Cementer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Channel Cementer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Channel Cementers are responsible for the installation and maintenance of underground utilities, specifically for laying and cementing pipes and conduits.

1. Pipe Installation

Install underground pipes and conduits for various purposes, such as water supply, sewage systems, gas distribution, and telecommunication networks.

- Excavate trenches to the specified depth and width.

- Lay pipes or conduits in the trenches, ensuring proper alignment and gradient.

- Backfill the trenches with excavated soil or other materials.

- Compact the backfill to provide stability and prevent settling.

2. Cementing

Prepare and apply cement mortar to seal joints between pipes or conduits and prevent leaks.

- Mix cement mortar according to specifications.

- Apply cement mortar to the joints using trowels or other tools.

- Smooth and finish the cement surfaces to ensure a watertight seal.

3. Inspection and Maintenance

Inspect installed pipes and conduits for defects or damage, and perform necessary repairs.

- Visually inspect pipes and conduits for cracks, leaks, or corrosion.

- Repair leaks by applying additional cement mortar or replacing damaged sections.

- Monitor and maintain the integrity of underground utility systems.

4. Safety and Compliance

Adhere to safety regulations and industry standards while performing job duties.

- Wear appropriate personal protective equipment (PPE), such as gloves, hard hats, and safety glasses.

- Follow established excavation and trenching safety procedures.

- Handle and dispose of hazardous materials properly.

Interview Tips

To prepare for an interview for a Channel Cementer position, candidates should focus on demonstrating their technical skills, experience, and commitment to safety. Here are some tips:

1. Research the Company and Industry

Learn about the company’s history, values, and recent projects. Research industry trends and best practices to show that you are knowledgeable and up-to-date.

- Visit the company’s website and social media pages.

- Read industry news and articles.

- Attend industry events or webinars.

2. Highlight Your Technical Skills

Emphasize your experience in pipe installation, cementing, and utility maintenance. Quantify your accomplishments whenever possible.

- Discuss projects where you successfully installed or repaired underground pipes or conduits.

- Provide specific examples of how you used cement mortar to create watertight seals.

- Describe your experience with trenching, excavation, and backfilling techniques.

3. Emphasize Safety and Compliance

Show the interviewer that you are committed to working safely and adhering to industry regulations. Highlight any safety training or certifications you have obtained.

- Describe your experience with PPE and excavation safety procedures.

- Discuss your knowledge of hazardous material handling and disposal regulations.

- Mention any safety initiatives or programs you have participated in.

4. Prepare Common Interview Questions

Practice answering common interview questions, such as:

- “Tell me about your experience in underground utility installation.”

- “How do you ensure the quality of your cementing work?”

- “What are your safety protocols when working in trenches or excavations?”

- “How do you stay up-to-date on industry best practices?”

5. Ask Informed Questions

At the end of the interview, ask thoughtful questions that demonstrate your interest and engagement. This shows the interviewer that you are genuinely interested in the position and the company.

- Ask about the company’s current projects or future plans.

- Inquire about opportunities for professional development or training.

- Ask about the company’s safety culture and accident prevention programs.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Channel Cementer, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Channel Cementer positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.