Are you gearing up for a career in Channeling Machine Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Channeling Machine Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

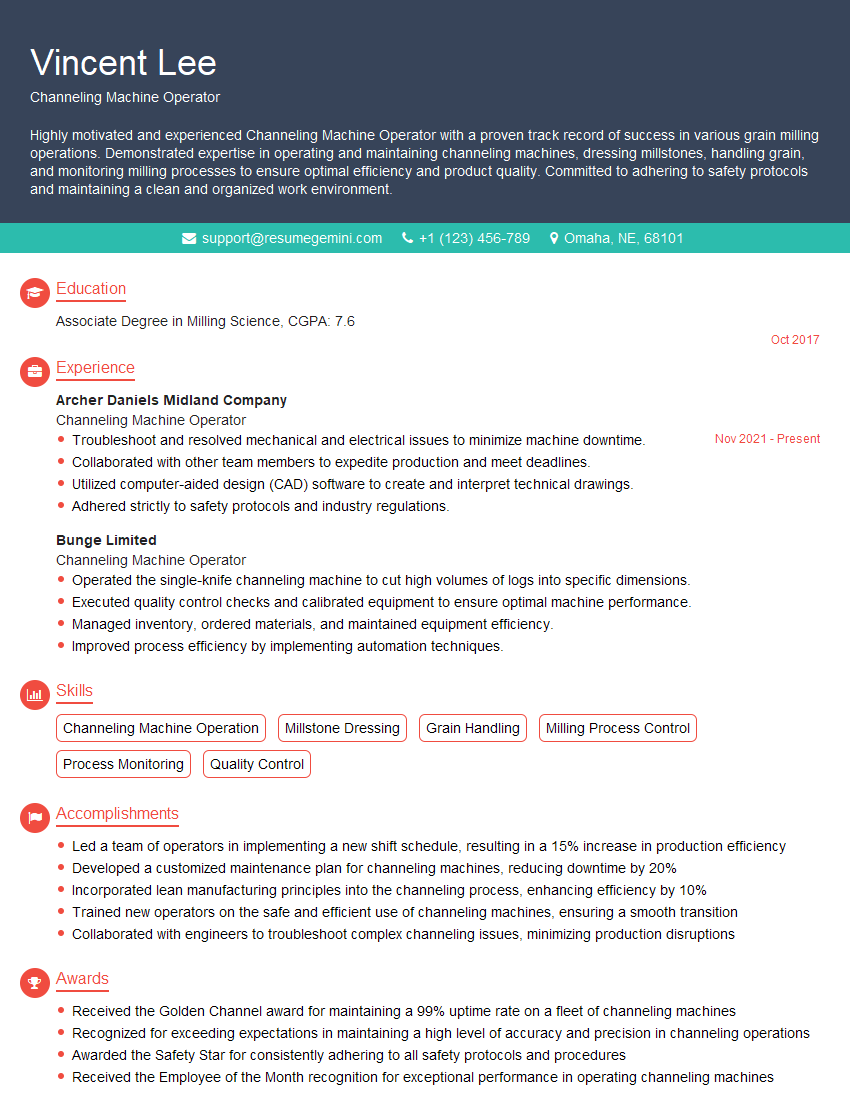

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Channeling Machine Operator

1. Explain the process of setting up a channeling machine?

- Power on the machine and ensure proper grounding.

- Load the appropriate tooling and secure it firmly.

- Set the machine parameters, including feed rate, spindle speed, and depth of cut.

- Position the workpiece and secure it using a vise or clamps.

- Align the machine tool with the workpiece using the machine’s precision adjustment features.

- Start the machine and monitor the cutting process to ensure proper operation.

2. Describe the different types of channeling machines and their applications?

CNC Channeling Machines

- Computer-controlled for high precision and repeatability.

- Can handle complex shapes and profiles.

- Suitable for mass production of channeled components.

Hydraulic Channeling Machines

- Use hydraulic force to drive the cutting tool.

- Provide high cutting force for thick materials.

- Used for cutting heavy-duty materials, such as structural steel.

Pneumatic Channeling Machines

- Use compressed air to drive the cutting tool.

- Offer higher speed and maneuverability.

- Suitable for light-duty channeling operations.

3. What are the safety precautions that must be observed when operating a channeling machine?

- Wear appropriate safety gear, including eye protection, earplugs, and gloves.

- Follow proper lockout/tagout procedures before performing maintenance or repairs.

- Avoid loose clothing or jewelry that could get caught in machine components.

- Ensure that the workpiece is securely clamped before starting the machine.

- Keep the work area clean and free of debris.

- Be aware of the machine’s cutting path and avoid contact with moving parts.

4. How do you troubleshoot common problems that occur during channeling operations?

Chattering

- Check for proper tool sharpness.

- Adjust the machine parameters, such as feed rate or spindle speed.

- Ensure that the workpiece is securely clamped.

Excessive Burrs

- Use a sharper cutting tool.

- Decrease the feed rate to allow for cleaner cutting.

- Check for proper machine alignment.

Tool Breakage

- Select the appropriate tool material and geometry for the job.

- Avoid excessive cutting forces by adjusting machine parameters.

- Check for proper tool mounting and alignment.

5. Explain the importance of maintaining channeling machines for optimal performance?

- Regular maintenance ensures that machine components are in good working condition.

- Reduces the risk of breakdowns and costly repairs.

- Extends the lifespan of the machine and tooling.

- Improves cutting accuracy and consistency.

- Ensures safe operation by preventing potential hazards.

6. Describe the techniques used for measuring the accuracy of channeled parts?

- Coordinate Measuring Machine (CMM): Non-contact measurement using a probe to determine the dimensions and geometry of the part.

- Optical Comparator: Projection or digital readout systems to compare the part against a known master template.

- Height Gauge: Manual or digital gauge for measuring the height, depth, and thickness of channeled features.

7. How do you optimize the cutting parameters for different materials and channeling applications?

- Consider the material’s hardness, thickness, and machinability.

- Adjust the feed rate and spindle speed to match the cutting tool’s recommended specifications.

- Use coolant to reduce friction, heat, and tool wear.

- Experiment with different cutting parameters to find the optimal combination for each application.

8. What are the common problems faced by channeling machine operators, and how do you resolve them?

Tool Wear

- Replace worn-out tools promptly.

- Adjust cutting parameters to reduce excessive wear.

- Lubricate the tool to extend its lifespan.

Machine Malfunction

- Refer to the machine manual for troubleshooting steps.

- Contact a qualified technician for repairs if necessary.

- Perform regular maintenance to prevent future malfunctions.

9. How do you stay updated with the latest advancements in channeling machine technology?

- Attend industry conferences and exhibitions.

- Read trade publications and technical journals.

- Participate in online forums and discussion groups.

10. Describe a challenging channeling project you worked on and how you overcame the technical difficulties?

- Highlight the specific technical challenges encountered, such as complex geometry or material properties.

- Explain the innovative solutions and techniques you implemented to overcome these challenges.

- Quantify the results achieved, such as improved accuracy, efficiency, or cost savings.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Channeling Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Channeling Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Channeling Machine Operators play a crucial role in manufacturing facilities. Their responsibilities include:1. Machine Operation and Maintenance

The Operator is responsible for setting up the channeling machine, programming it for specific operations, and performing automated or semi-automated channeling processes. They ensure optimal machine performance by conducting regular maintenance checks, identifying and addressing any potential issues to prevent breakdowns.

2. Material Handling

Operators are responsible for loading and unloading materials into the machine. They need to ensure the materials are placed correctly and securely for the channeling process. They may also need to adjust the machine settings to accommodate different material types.

3. Quality Assurance

Operators monitor the channeling process to ensure the produced parts meet the required specifications. They inspect the channeled parts for accuracy, surface finish, and other quality parameters. They may also perform tests to verify the integrity of the parts.

4. Process Optimization

Experienced Operators identify opportunities to improve production efficiency and product quality. They may suggest modifications to the channeling process, machine settings, or material handling techniques to enhance overall performance and reduce defects.

Interview Tips

Interview Preparation is crucial for success. Here are some proven tips:

1. Research and Know the Company

Before the interview, thoroughly research the company and its products. Understand their business operations, industry position, and any recent developments. This knowledge demonstrates your interest and enthusiasm for the opportunity.

2. Practice Common Interview Questions

Prepare for standard interview questions such as “Tell me about yourself” or “Why are you interested in this role?”. Practice your answers to articulate your skills, experience, and fit for the position effectively.

3. Highlight Transferable Skills

If you don’t have direct experience as a Channeling Machine Operator, emphasize transferable skills that are relevant to the role. For example, if you’ve worked on other types of machinery or have strong attention to detail and problem-solving abilities, be sure to highlight these in your answers.

4. Ask Informed Questions

Prepare thoughtful questions to ask the interviewer at the end of the interview. This shows your engagement and interest in the role and the company. Ask questions about the company’s growth plans, the team you’d be working with, or the opportunities for professional development.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Channeling Machine Operator, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Channeling Machine Operator positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.