Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Cut Out Stitcher position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

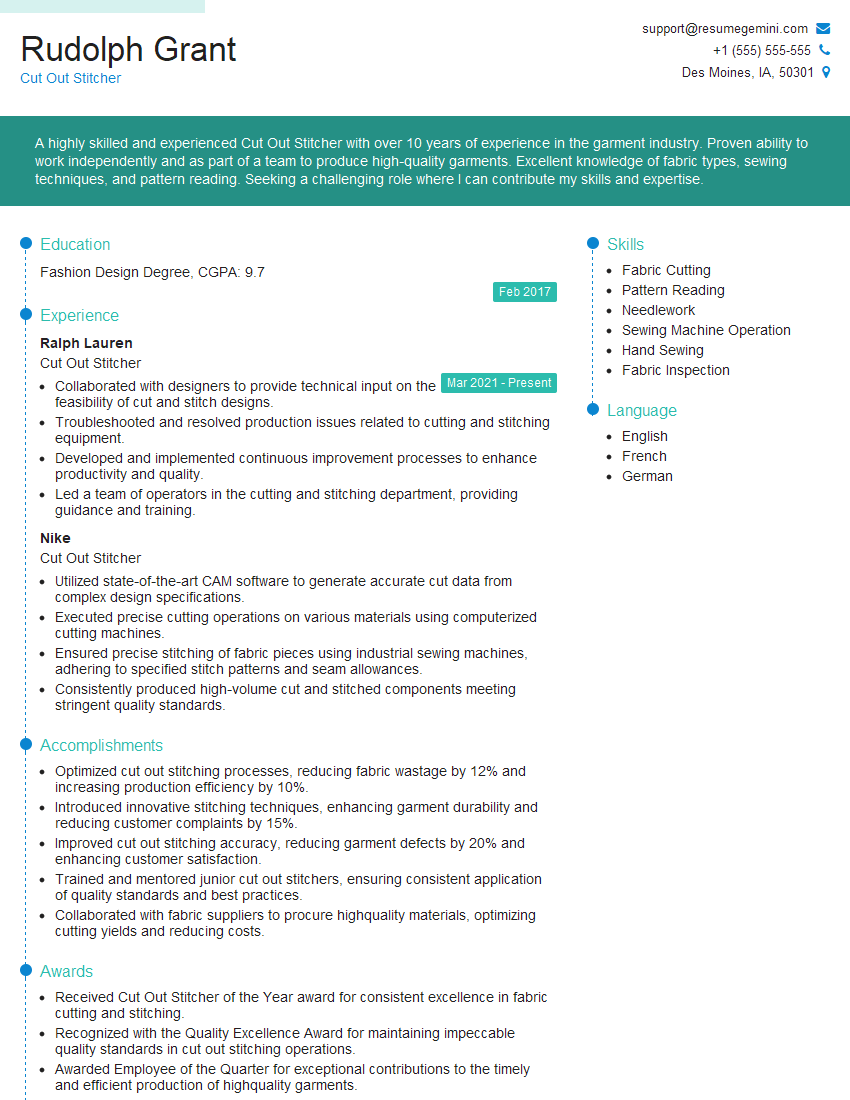

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Cut Out Stitcher

1. How do you ensure the accuracy and consistency of your stitching operations?

To ensure the accuracy and consistency of my stitching operations, I follow a meticulous process that involves the following steps:

- Precise Machine Calibration: Before starting any stitching task, I thoroughly calibrate my stitching machine to ensure accurate needle placement and tension settings.

- Material Inspection: I carefully inspect the fabric and interfacing before stitching to identify any defects or variations that may impact the stitch quality.

- Sample Stitching: I perform sample stitches on scrap fabric to optimize stitch settings and ensure the desired stitch length and density.

- Regular Maintenance: I perform regular maintenance on my stitching machine, including cleaning, oiling, and replacing needles, to keep it in optimal working condition.

2. Describe your experience in working with different types of fabrics and materials.

Seam Finishes

- Serging: I am proficient in using a serger to create clean, enclosed seam finishes that prevent fraying and unraveling.

- Binding: I have experience in creating various binding finishes, such as single-fold, double-fold, and bias binding, to provide a professional and decorative touch.

Interfacing

- Fusible Interfacing: I am skilled in using fusible interfacing to stabilize fabrics, add body, and improve the overall durability of garments.

- Non-Fusible Interfacing: I have experience in sewing with non-fusible interfacing, such as canvas or buckram, to provide support and structure to garments.

3. How do you handle delicate fabrics and trims?

When working with delicate fabrics and trims, I take extra care to prevent damage and ensure a high-quality finish. My approach includes the following steps:

- Using the Right Needles: I use fine needles specifically designed for delicate fabrics to minimize fabric damage and prevent snagging.

- Adjusting Stitch Settings: I adjust stitch length and tension to suit the fabric’s weight and drape, ensuring secure stitching without puckering or stretching.

- Hand Stitching: For intricate details or areas where machine stitching may be too harsh, I opt for hand stitching to maintain the fabric’s integrity.

4. What is your process for troubleshooting stitching problems?

To effectively troubleshoot stitching problems, I follow a systematic approach that involves the following steps:

- Identifying Symptoms: I carefully observe the stitching and identify the specific symptoms of the problem, such as skipped stitches, puckering, or uneven tension.

- Checking Machine Settings: I verify that the machine settings, including needle size, thread tension, and stitch length, are appropriate for the fabric and thread being used.

- Inspecting Materials: I examine the fabric, thread, and needle for any defects or damage that may be causing the problem.

- Troubleshooting and Adjustments: Based on my observations, I make necessary adjustments to the machine settings or replace damaged components to resolve the issue.

5. How do you stay updated with the latest advancements in stitching techniques and equipment?

To stay abreast of the latest advancements in stitching techniques and equipment, I engage in continuous learning and development activities:

- Industry Publications: I subscribe to industry publications and online resources that provide information on new technologies, techniques, and best practices.

- Trade Shows and Events: I attend trade shows and industry events to witness live demonstrations of new equipment and learn from experts in the field.

- Online Courses and Workshops: I enroll in online courses and attend workshops to enhance my skills and knowledge in specialized stitching techniques.

6. How do you manage your time and workload effectively?

To manage my time and workload effectively, I prioritize tasks, plan my day, and maintain organization:

- Prioritizing Tasks: I assess the importance and urgency of tasks to determine which ones to focus on first.

- Scheduling and Planning: I create a daily schedule that allocates specific time slots for different tasks, ensuring a balanced workload.

- Organized Workspace: I maintain a clean and organized workspace to minimize distractions and maximize efficiency.

7. What are the safety precautions you take while operating stitching equipment?

To ensure safety while operating stitching equipment, I adhere to the following precautions:

- Machine Inspection: Before using any equipment, I inspect it thoroughly for any damage or malfunctions.

- Protective Gear: I wear appropriate protective gear, such as safety glasses and earplugs, to minimize risks.

- Proper Training: I have received comprehensive training on the safe operation of stitching equipment and follow all established safety protocols.

8. How do you work effectively as part of a team in a fast-paced manufacturing environment?

To work effectively as part of a team in a fast-paced manufacturing environment, I:

- Communication: I actively communicate with my team members to ensure clear understanding of tasks and deadlines.

- Collaboration: I collaborate with others to solve problems, share ideas, and support each other’s work.

- Adaptability: I am adaptable to changing priorities and workload demands, and I can adjust my schedule accordingly.

9. What are your strengths and weaknesses as a Cut Out Stitcher?

Strengths

- Accuracy and Precision: I possess a keen eye for detail and take pride in producing precise and consistent stitches.

- Technical Skills: I am proficient in operating a range of stitching machines and can troubleshoot and resolve technical issues independently.

- Teamwork and Collaboration: I am a cooperative team player who enjoys working with others to achieve common goals.

Weaknesses

- Speed: While I prioritize accuracy, I am working on improving my stitching speed to meet production demands.

- Experience with Specialty Fabrics: I am eager to expand my experience in working with specialty fabrics, such as leather or lace.

10. How do you measure success in your role as a Cut Out Stitcher?

I measure my success as a Cut Out Stitcher based on the following criteria:

- Quality of Work: I strive to produce high-quality stitches that meet or exceed customer specifications.

- Efficiency: I am committed to completing tasks within established timeframes while maintaining accuracy.

- Customer Satisfaction: My ultimate goal is to contribute to the production of garments that meet customer expectations and enhance their satisfaction.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Cut Out Stitcher.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Cut Out Stitcher‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Cut Out Stitchers are responsible for operating sewing machines to cut, sew, and bind materials together to create a variety of products, such as garments, bags, and toys.

1. Machine Operation

Operate sewing machines to cut, sew, and bind materials together.

- Set up and adjust machines according to job specifications.

- Monitor machines and ensure they are running properly.

2. Material Handling

Handle materials carefully to avoid damage.

- Load and unload materials from machines.

- Inspect materials for defects.

3. Quality Control

Inspect products to ensure they meet quality standards.

- Check for defects in seams, stitching, and materials.

- Make adjustments to machines or materials as needed.

4. Production

Meet production goals and deadlines.

- Work quickly and efficiently to produce a high volume of products.

- Follow production schedules and instructions.

Interview Tips

To prepare for an interview for a Cut Out Stitcher position, it is important to:

1. Research the Company and Position

Learn as much as you can about the company you are applying to and the specific position you are interviewing for.

- Visit the company website to learn about their products, services, and culture.

- Read online reviews from current and former employees to get an insider’s perspective.

2. Practice Your Answers

Take some time to practice answering common interview questions.

- Use the STAR method to structure your answers: Situation, Task, Action, Result.

- Provide specific examples from your work experience that demonstrate your skills and abilities.

3. Dress Professionally

First impressions matter, so it is important to dress professionally for your interview.

- Wear clean, pressed clothes that are appropriate for the company culture.

- Make sure your hair and nails are neat and tidy.

4. Be Enthusiastic and Positive

Employers want to hire people who are enthusiastic and passionate about their work.

- Be positive and upbeat throughout the interview.

- Show that you are genuinely interested in the position and the company.

5. Ask Questions

Asking questions at the end of the interview shows that you are engaged and interested in the position.

- Prepare a few questions to ask the interviewer about the company, the position, or the industry.

- This shows that you are interested in learning more about the opportunity.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Cut Out Stitcher, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Cut Out Stitcher positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.