Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Finishing Area Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

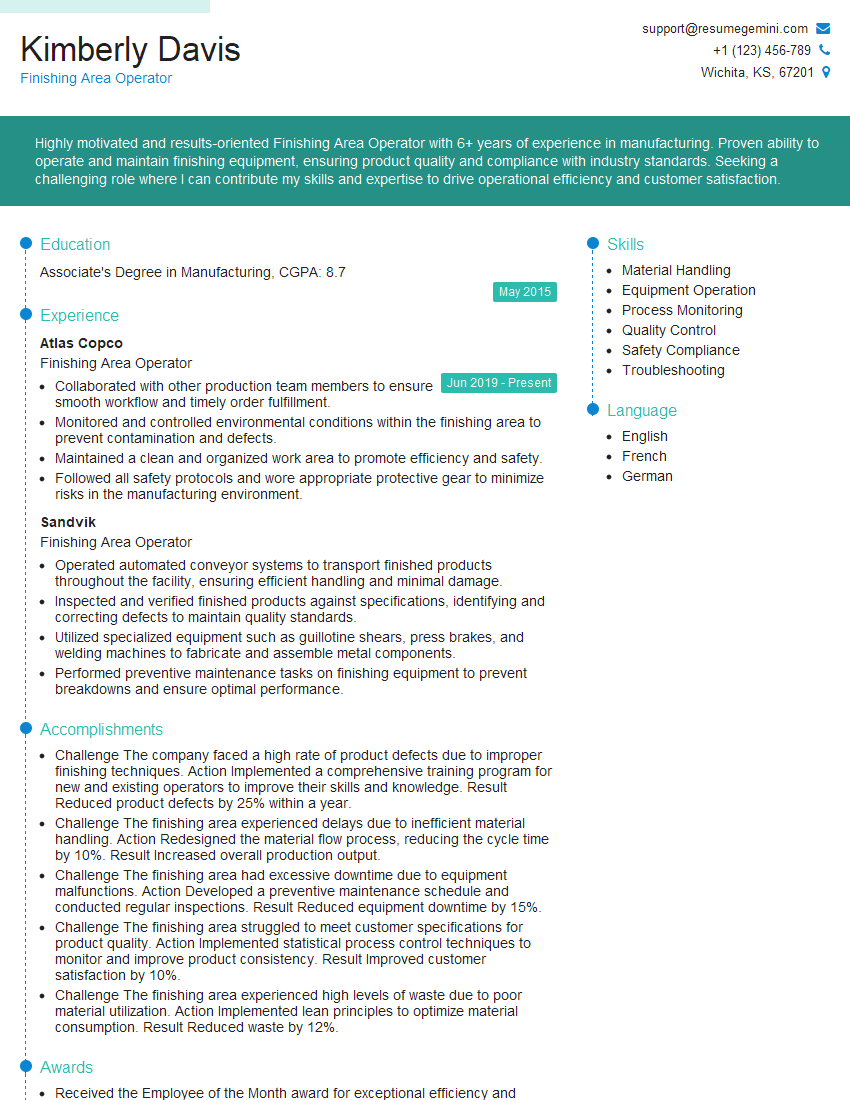

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Finishing Area Operator

1. What are the different types of finishing operations performed in a metalworking environment?

In a metalworking environment, various finishing operations are performed to enhance the surface characteristics of metal components. These operations include:

- Grinding: Removing excess material and shaping the workpiece using abrasive wheels.

- Polishing: Creating a smooth and shiny surface by removing imperfections using abrasive belts or pads.

- Buffing: Creating a highly reflective surface by applying a fine abrasive compound to a rotating buffing wheel.

- Deburring: Removing sharp edges and burrs from the workpiece using hand tools or automated equipment.

- Sandblasting: Using abrasive particles propelled by compressed air to clean or roughen surfaces.

2. Describe the process of deburring a metal workpiece.

Deburring by Hand

- Identify all sharp edges and burrs on the workpiece.

- Select appropriate hand tools, such as a file, scraper, or burr remover.

- Carefully remove the burrs by hand, taking care not to damage the workpiece surface.

Automated Deburring

- Utilize automated deburring machines, such as vibratory deburring or centrifugal barrel finishing.

- Place the workpieces in the machine along with abrasive media.

- Run the machine for a specified time to remove the burrs.

3. What are the safety precautions that must be followed when operating finishing equipment?

To ensure a safe working environment, it is crucial to adhere to the following safety precautions:

- Wear appropriate personal protective equipment (PPE): Eye protection, gloves, earplugs, and a respirator if necessary.

- Inspect equipment before use: Check for any damage or loose parts that could compromise safety.

- Follow proper machine operating procedures: Read and understand the manufacturer’s instructions for each piece of equipment.

- Keep work area clean and organized: Remove scrap material, debris, and tripping hazards to prevent accidents.

- Never operate equipment while under the influence of drugs or alcohol: Impaired judgment and coordination can lead to dangerous situations.

4. What are the different types of abrasive materials used in finishing operations?

In finishing operations, a variety of abrasive materials are employed to achieve desired surface finishes. These include:

- Natural abrasives: Occurring naturally in the environment, such as sand, pumice, and emery.

- Synthetic abrasives: Manufactured artificially, offering higher consistency and performance, such as aluminum oxide, silicon carbide, and diamond.

- Bonded abrasives: Abrasive particles bonded together using a resin, ceramic, or metal matrix, forming grinding wheels, sanding belts, and polishing discs.

- Coated abrasives: Abrasive particles coated onto a flexible backing, such as sandpaper, emery cloth, and abrasive pads.

5. How do you select the appropriate abrasive grit size for a particular finishing operation?

Selecting the correct abrasive grit size is crucial to achieve the desired surface finish. Here are the guidelines:

- Coarse grit (low number): Removes large amounts of material quickly, used for initial shaping and heavy stock removal.

- Medium grit: Smooths surfaces and removes smaller imperfections, used for general-purpose finishing.

- Fine grit (high number): Creates a very smooth and refined surface, used for polishing and final finishing.

- Consider the workpiece material and desired finish: Harder materials require finer grits, while softer materials can tolerate coarser grits.

6. What techniques can be used to improve the surface finish of a metal workpiece?

Various techniques can enhance the surface finish of a metal workpiece:

- Multi-step grinding and polishing: Using progressively finer grits to remove imperfections and create a smooth surface.

- Buffing: Applying a fine abrasive compound to a rotating buffing wheel to achieve a high-gloss finish.

- Electropolishing: Electrochemically dissolving the surface layer to remove imperfections and create a smooth, corrosion-resistant finish.

- Chemical polishing: Immersing the workpiece in a chemical solution to dissolve and smooth the surface.

7. How do you maintain and calibrate finishing equipment?

To ensure optimal performance and accuracy, finishing equipment requires regular maintenance and calibration:

- Regular cleaning: Remove dust, debris, and metal particles to prevent equipment malfunctions.

- Lubrication: Follow manufacturer’s instructions to lubricate moving parts and reduce wear and tear.

- Calibration: Use precision measuring instruments to verify the accuracy of equipment settings and ensure consistent results.

- Preventive maintenance: Conduct scheduled inspections and repairs to identify and address potential issues before they become major problems.

8. What factors influence the choice of finishing method for a particular application?

The selection of a finishing method depends on several factors:

- Workpiece material: Different materials respond differently to various finishing techniques.

- Desired surface finish: The required level of smoothness, gloss, and surface texture must be considered.

- Production volume: High-volume production may necessitate automated finishing processes.

- Cost and efficiency: The cost and efficiency of different finishing methods should be evaluated.

- Environmental regulations: Some finishing methods may have environmental implications that need to be addressed.

9. What are the latest advancements in finishing technologies?

The finishing industry is constantly evolving, with new technologies emerging to improve efficiency and quality:

- Laser finishing: Using lasers for precise cutting, engraving, and surface texturing.

- Abrasive waterjet cutting: Combining water and abrasive particles to create high-pressure streams for intricate cutting and finishing.

- Electrochemical machining (ECM): Using electrochemical reactions to shape and finish metal workpieces.

- Automated finishing systems: Incorporating robots and other automation technologies to enhance productivity and consistency.

10. How do you stay up-to-date with the latest finishing techniques and industry trends?

To maintain a competitive edge and expand my knowledge, I actively engage in the following:

- Industry publications and journals: Subscribing to and reading magazines and journals dedicated to finishing technologies.

- Trade shows and conferences: Attending industry events to learn about new products, technologies, and best practices.

- Online resources: Utilizing websites, forums, and technical articles to access up-to-date information.

- Training and workshops: Participating in training programs and workshops offered by equipment manufacturers and industry associations.

- Networking: Connecting with other professionals in the field to exchange knowledge and insights.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Finishing Area Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Finishing Area Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Finishing Area Operators play a crucial role in ensuring the quality and efficiency of production processes in various industries, including manufacturing, packaging, and automotive. Their primary responsibilities involve:

1. Operating and Maintaining Finishing Equipment

Setting up, operating, and maintaining finishing equipment, such as conveyor belts, spray booths, and printing machines.

- Monitoring equipment performance and making adjustments as needed.

- Troubleshooting and resolving equipment malfunctions promptly.

2. Applying Finishes

Applying coatings, paints, or other finishing materials to products according to specifications.

- Ensuring proper coverage and adhesion of finishes.

- Inspecting surfaces for defects and making necessary touch-ups.

3. Quality Control

Inspecting finished products for defects, such as scratches, dents, and paint imperfections.

- Identifying and correcting quality issues promptly.

- Maintaining records of inspection results.

4. Material Handling

Loading and unloading materials from finishing equipment.

- Following safety protocols for handling hazardous materials.

- Maintaining a clean and organized work area.

5. Adherence to Safety Regulations

Understanding and adhering to all safety regulations and procedures.

- Wearing appropriate personal protective equipment (PPE).

- Maintaining a safe and hazard-free work environment.

Interview Tips

To ace an interview for a Finishing Area Operator position, candidates can follow these tips:

1. Research the Company and Position

Familiarize yourself with the company’s products, services, and industry. Review the job description thoroughly to understand the specific responsibilities and requirements of the role.

- Prepare questions to ask the interviewer that demonstrate your interest in the position and the company.

2. Highlight Relevant Skills and Experience

Emphasize your technical skills in operating finishing equipment, applying finishes, and performing quality control. Showcase any prior experience in manufacturing or packaging operations.

- Quantify your accomplishments with specific examples and metrics to demonstrate your impact.

3. Demonstrate Attention to Detail and Quality

Convey your commitment to accuracy and taking pride in your work. Explain how you have consistently exceeded quality standards in previous roles.

- Mention any experience in using inspection tools and techniques to identify and resolve defects.

4. Emphasize Safety and Compliance

Highlight your understanding of safety regulations and your adherence to established protocols. Explain how you have contributed to a safe and compliant work environment in previous positions.

- Discuss your knowledge of hazardous materials handling and proper PPE usage.

5. Show Enthusiasm and Motivation

Demonstrate your passion for working in a manufacturing environment and your eagerness to contribute to the team’s success. Express your interest in the company’s products or services and how you can add value.

- Convey your willingness to learn and grow within the organization.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Finishing Area Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.