Are you gearing up for a career in Heel Attacher? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Heel Attacher and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

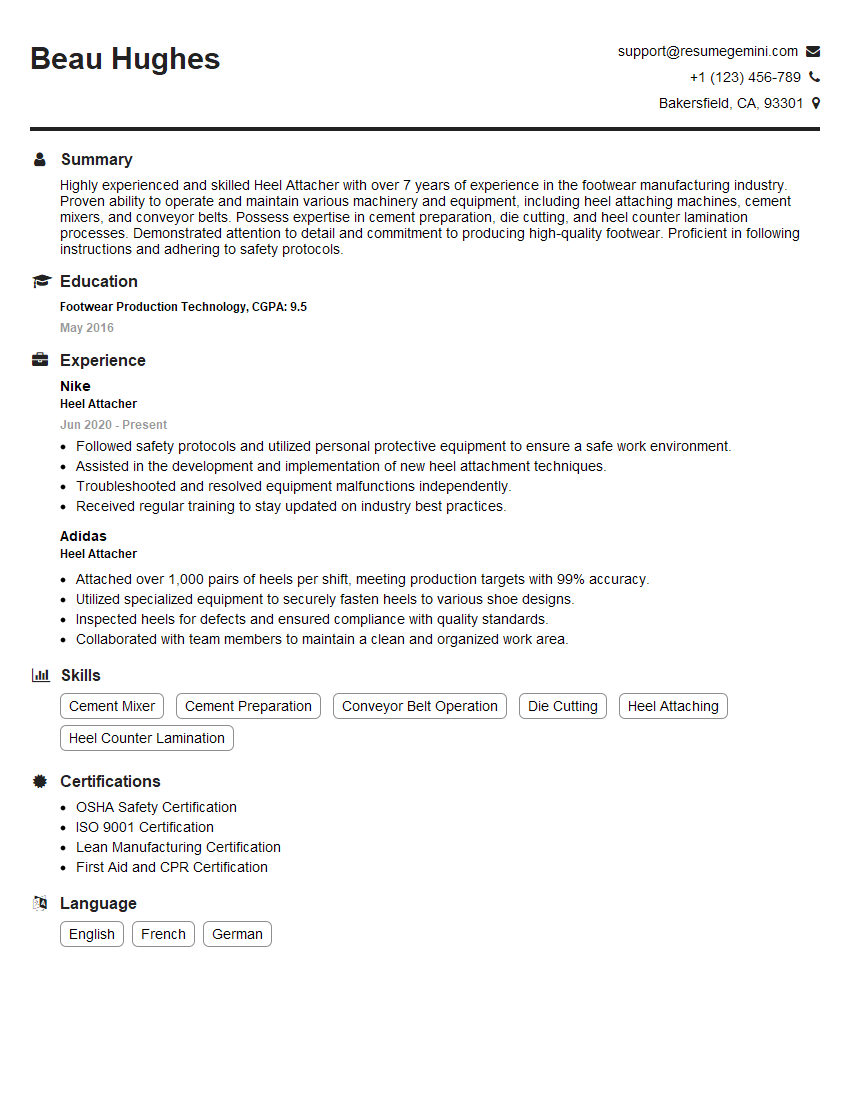

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Heel Attacher

1. Describe the different types of materials that can be used to make shoe heels?

- Leather: This is a classic material used to make shoe heels. It is durable, flexible, and breathable, making it a comfortable option for all-day wear.

- Rubber: Rubber is another popular material for shoe heels. It is lightweight, flexible, and provides good traction, making it ideal for shoes that are worn for walking or running.

- Plastic: Plastic is a versatile material that can be used to make a variety of shoe heels. It is lightweight, durable, and can be molded into a variety of shapes.

- Wood: Wood is a traditional material used to make shoe heels. It is strong, durable, and can be stained or painted to match any shoe style.

- Metal: Metal is a less common material used to make shoe heels. It is strong, durable, and can be polished to a high shine. However, metal heels can be heavy and uncomfortable to wear.

2. What are the different types of heel shapes?

- Stiletto: The stiletto is a thin, high heel that is typically worn on dress shoes. It is a classic and elegant heel shape that can make any outfit look more formal.

- Block: The block heel is a thick, square heel that is typically worn on casual shoes. It is a comfortable and stable heel shape that is ideal for all-day wear.

- Wedge: The wedge heel is a solid piece of material that extends from the toe to the heel. It is a comfortable and stylish heel shape that can be worn on a variety of shoes.

- Kitten: The kitten heel is a short, low heel that is typically worn on office shoes. It is a feminine and elegant heel shape that is both comfortable and stylish.

- Cone: The cone heel is a heel that is wider at the top than at the bottom. It is a modern and trendy heel shape that can be worn on a variety of shoes.

3. What are the different types of heel heights?

- Low heels: Low heels are typically less than 2 inches tall. They are a comfortable and versatile heel height that can be worn on a variety of shoes.

- Mid heels: Mid heels are typically between 2 and 4 inches tall. They are a more formal heel height that is often worn on dress shoes and office shoes.

- High heels: High heels are typically over 4 inches tall. They are a dramatic and glamorous heel height that is often worn on evening shoes and special occasion shoes.

4. What are the different types of heel attachments?

- Nailed heels: Nailed heels are attached to the shoe using nails. This is a traditional method of heel attachment that is still used today.

- Screwed heels: Screwed heels are attached using screws. This is now more common method attaching heels as it is more secure than using nails.

- Glued heels: Glued heels are attached using glue. However, this is not a very recommended form of heel attachment as less secure and durable.

5. What are the different types of heel tips?

- Rubber heel tips: Rubber heel tips are the most common type of heel tip. They are durable and provide good traction.

- Metal heel tips: Metal heel tips are less common, but they are more durable than rubber heel tips. They can also be polished to a high shine.

- Plastic heel tips: Plastic heel tips are a less durable option, but they are lightweight and inexpensive.

6. What are the different tools used to attach heels?

- Heel nailer: A heel nailer is a tool used to drive nails into heels. It is a specialized tool that is not typically found in home toolkits.

- Screwdriver: A screwdriver is used to drive screws into heels. It is a more common tool that is likely to be found in home toolkits.

- Hammer: A hammer is used to drive nails into heels. It is a basic tool that is likely to be found in home toolkits.

- Glue gun: A glue gun is used to apply glue to heels. It is a specialized tool that is not typically found in home toolkits.

7. What are the different safety precautions that should be taken when attaching heels?

- Always wear safety glasses when attaching heels. This will protect your eyes from flying nails or debris.

- Be sure to use the correct tools for the job. Using the wrong tools can damage the heel or cause injury.

- Never attempt to attach a heel without first checking to make sure that the shoe is properly fitted. A poorly fitted shoe can cause the heel to come loose, which can lead to injury.

- Never attempt to attach a heel if you are not comfortable doing so. If you are not sure how to attach a heel, it is best to take the shoe to a professional shoe repair shop.

8. What are the different types of defects that can occur when attaching heels?

- The heel may be attached at an angle.

- The heel may be attached too high or too low on the shoe.

- The heel may be attached too tightly or too loosely.

- The heel may be attached with the wrong type of adhesive.

- The heel may be attached to a shoe that is not properly fitted.

9. What are the different ways to prevent defects when attaching heels?

- Use the correct tools for the job.

- Make sure that the shoe is properly fitted before attaching the heel.

- Follow the manufacturer’s instructions for attaching the heel.

- Inspect the heel after it has been attached to make sure that it is secure and properly aligned.

10. What are the different types of maintenance that should be performed on heels?

- Heels should be inspected regularly for signs of wear and tear.

- Heels should be replaced if they are damaged or worn down.

- Heels should be cleaned and polished regularly to keep them looking their best.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Heel Attacher.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Heel Attacher‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Heel Attachers are primarily responsible for attaching heels to footwear utilizing specialized equipment and adhesives. Their duties involve ensuring the proper alignment, positioning, and secure bonding of heels to uppers and soles. They may also perform other tasks related to footwear production.

1. Heel Attachment

The primary responsibility of a Heel Attacher is to attach heels to footwear. This includes:

- Selecting the appropriate heel type, size, and material for each shoe style.

- Preparing the heel and shoe upper for bonding by cleaning and applying adhesives.

- Positioning the heel on the shoe upper and aligning it according to specifications.

- Applying pressure or heat to activate the adhesive and ensure a secure bond.

2. Quality Control

Heel Attachers are responsible for maintaining the quality of their work:

- Inspecting heels for defects or damage before attachment.

- Checking heel alignment, positioning, and bonding strength after attachment.

- Performing regular maintenance and calibration of equipment to ensure precision.

3. Production Efficiency

Heel Attachers contribute to the overall efficiency of footwear production:

- Optimizing work processes to minimize time and material waste.

- Maintaining a clean and organized workstation.

- Working effectively as part of a team to meet production targets.

4. Safety Compliance

Heel Attachers adhere to safety protocols to ensure a safe working environment:

- Wearing appropriate personal protective equipment (PPE), including safety goggles and gloves.

- Following established procedures for handling adhesives and using equipment.

- Maintaining a clean and hazard-free work area.

Interview Tips

To ace an interview for a Heel Attacher position, candidates should prepare thoroughly and showcase their skills and experience.

1. Research the Company and Position

Familiarize yourself with the company’s website, social media presence, and industry reputation. Research the specific job requirements, including responsibilities, qualifications, and skills.

- Demonstrate your understanding of the company’s products, values, and mission.

- Show that you have researched the industry and are aware of current trends and best practices.

2. Highlight Relevant Skills and Experience

Tailor your resume and interview answers to the job requirements. Quantify your accomplishments and provide specific examples of your skills:

- Emphasize your experience in heel attachment techniques, including different heel types and materials.

- Highlight your attention to detail, precision, and quality control measures.

- Describe your ability to work efficiently and meet production targets.

3. Practice Answering Common Interview Questions

Prepare for typical interview questions by researching common questions and formulating thoughtful responses:

- Tell me about your experience in heel attachment.

- How do you ensure the quality and accuracy of your work?

- Describe a time when you faced a challenge in heel attachment and how you overcame it.

4. Be Enthusiastic and Professional

Show your interest in the position and the company. Dress professionally, arrive on time, and maintain eye contact during the interview.

- Express your motivation for applying for the role.

- Be confident in your abilities and show enthusiasm for the footwear industry.

Next Step:

Now that you’re armed with the knowledge of Heel Attacher interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Heel Attacher positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini