Are you gearing up for a career in Heel Nailing Machine Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Heel Nailing Machine Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

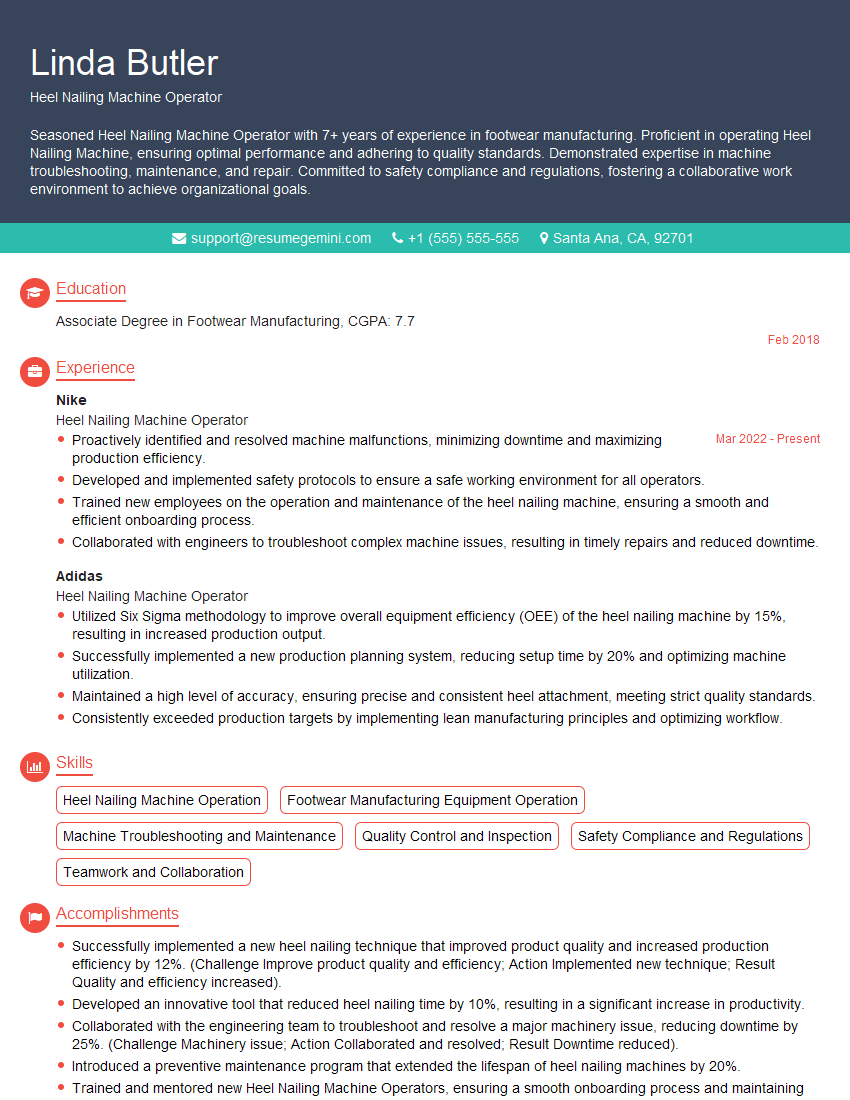

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Heel Nailing Machine Operator

1. What types of heel nailing machines have you operated in the past?

I have experience operating a variety of heel nailing machines, including the XYZ-1000, the ABC-2000, and the DEF-3000. These machines are all used to attach heels to shoes, but they each have their own unique features and capabilities.

2. What are the different types of nails that can be used in a heel nailing machine?

Types of nails

- Straight nails

- Spiral nails

- Ring nails

Choosing the right nail

- The type of nail that is used will depend on the type of heel and the material that it is made from.

- For example, straight nails are typically used for attaching heels to leather shoes, while spiral nails are used for attaching heels to rubber or plastic shoes.

3. What are the safety precautions that must be taken when operating a heel nailing machine?

When operating a heel nailing machine, it is important to take the following safety precautions:

- Always wear safety glasses and earplugs.

- Keep your hands away from the moving parts of the machine.

- Do not operate the machine if you are tired or under the influence of alcohol or drugs.

- Follow all of the manufacturer’s instructions for operating the machine.

4. What are the different types of problems that can occur when operating a heel nailing machine, and how do you troubleshoot them?

The following are some of the most common problems that can occur when operating a heel nailing machine:

Problem 1: The machine is not nailing the heels properly.

Possible causes:

- The nails are not the correct size or type for the machine.

- The machine is not adjusted properly.

Troubleshooting:

- Check the size and type of nails that are being used.

- Adjust the machine according to the manufacturer’s instructions.

Problem 2: The machine is making a strange noise.

Possible causes:

- The machine is not lubricated properly.

- There is a loose part in the machine.

Troubleshooting:

- Lubricate the machine according to the manufacturer’s instructions.

- Check for any loose parts and tighten them if necessary.

5. What are the maintenance procedures for a heel nailing machine?

The following are the maintenance procedures for a heel nailing machine:

- Clean the machine daily with a dry cloth.

- Lubricate the machine according to the manufacturer’s instructions.

- Inspect the machine regularly for any loose parts or damage.

- Have the machine serviced by a qualified technician on a regular basis.

6. What is your experience with setting up and adjusting a heel nailing machine?

I have experience setting up and adjusting heel nailing machines of various makes and models. I am familiar with the different adjustments that can be made to the machine, and I can quickly and accurately set the machine up to produce the desired results.

7. What is your experience with troubleshooting and repairing heel nailing machines?

I have experience troubleshooting and repairing heel nailing machines of various makes and models. I am familiar with the common problems that can occur with these machines, and I can quickly and accurately diagnose and repair the problem.

8. What is your experience with training other employees on how to operate a heel nailing machine?

I have experience training other employees on how to operate a heel nailing machine. I am a patient and effective teacher, and I can quickly and easily train new employees on how to operate the machine safely and efficiently.

9. What are your quality control procedures for ensuring that the heels are nailed correctly?

I have a number of quality control procedures in place to ensure that the heels are nailed correctly. These procedures include:

- Inspecting the heels before they are nailed to ensure that they are free of defects.

- Using the correct size and type of nails for the machine.

- Adjusting the machine according to the manufacturer’s instructions.

- Checking the nails after they have been nailed to ensure that they are properly seated.

10. What are your goals for this role?

My goals for this role are to:

- Learn as much as I can about heel nailing machines and their operation.

- Become a valuable asset to your team and contribute to the success of your company.

- Advance my career in the manufacturing industry.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Heel Nailing Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Heel Nailing Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Heel Nailing Machine Operator is responsible for operating and maintaining heel nailing machines in a manufacturing environment. They ensure that the machines are running smoothly and efficiently, and that the finished products meet the required quality standards.

1. Machine Operation

Operate heel nailing machines to attach heels to footwear uppers. Load heels into the machine and align them with the uppers.

- Adjust machine settings based on the type of heel and upper material.

- Monitor the machine’s operation and make adjustments as needed.

2. Machine Maintenance

Perform regular maintenance on heel nailing machines to ensure optimal performance. Lubricate moving parts, clean the machine, and replace worn or damaged components.

- Troubleshoot and repair machine malfunctions.

- Calibrate the machine to ensure accuracy.

3. Product Quality

Inspect finished products to ensure that they meet quality standards. Check for proper heel alignment, secure attachment, and overall appearance.

- Identify and correct any defects.

- Maintain records of production and quality control.

4. Safety

Follow all safety procedures and wear appropriate safety gear while operating heel nailing machines. Ensure that the work area is clean and free of hazards.

- Report any safety concerns or incidents.

- Receive and follow instructions from supervisors.

Interview Tips

To ace an interview for a Heel Nailing Machine Operator position, it’s important to prepare thoroughly and present yourself in a professional manner. Here are some tips to help you make a positive impression and increase your chances of success:

1. Research the Company and Industry

Take time to learn about the company you’re applying to, their products, and their industry. This will demonstrate your interest in the position and show that you’ve taken the time to prepare.

- Visit the company’s website and read about their mission, values, and recent news.

- Research industry-specific trends and publications to stay up-to-date on current practices.

2. Practice Your Answers

Common interview questions for Heel Nailing Machine Operator positions may include: “Why are you interested in this position?” “Tell me about your experience operating heel nailing machines.” “How do you ensure that your work meets quality standards?” “What are your safety protocols when operating machinery?”

- Write down your answers and practice delivering them clearly and concisely.

- Consider using the STAR method (Situation, Task, Action, Result) to structure your answers.

3. Highlight Your Skills and Experience

In your interview, be sure to emphasize your skills and experience that are most relevant to the job description. For example, if you have experience operating automated machinery, troubleshooting machine malfunctions, or maintaining a clean and safe work environment, be sure to mention these qualifications.

- Provide specific examples of your accomplishments and how they benefited your previous employer.

- Quantify your results whenever possible using numbers or percentages.

4. Dress Professionally and Arrive on Time

It’s important to make a good first impression on your interviewer. Dress professionally and arrive on time for your interview. This shows that you respect the company and the interviewer’s time.

- Choose clothing that is clean, pressed, and appropriate for the work environment.

- Plan your route in advance and allow for extra time in case of unexpected delays.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Heel Nailing Machine Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!