Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Insole Presser position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

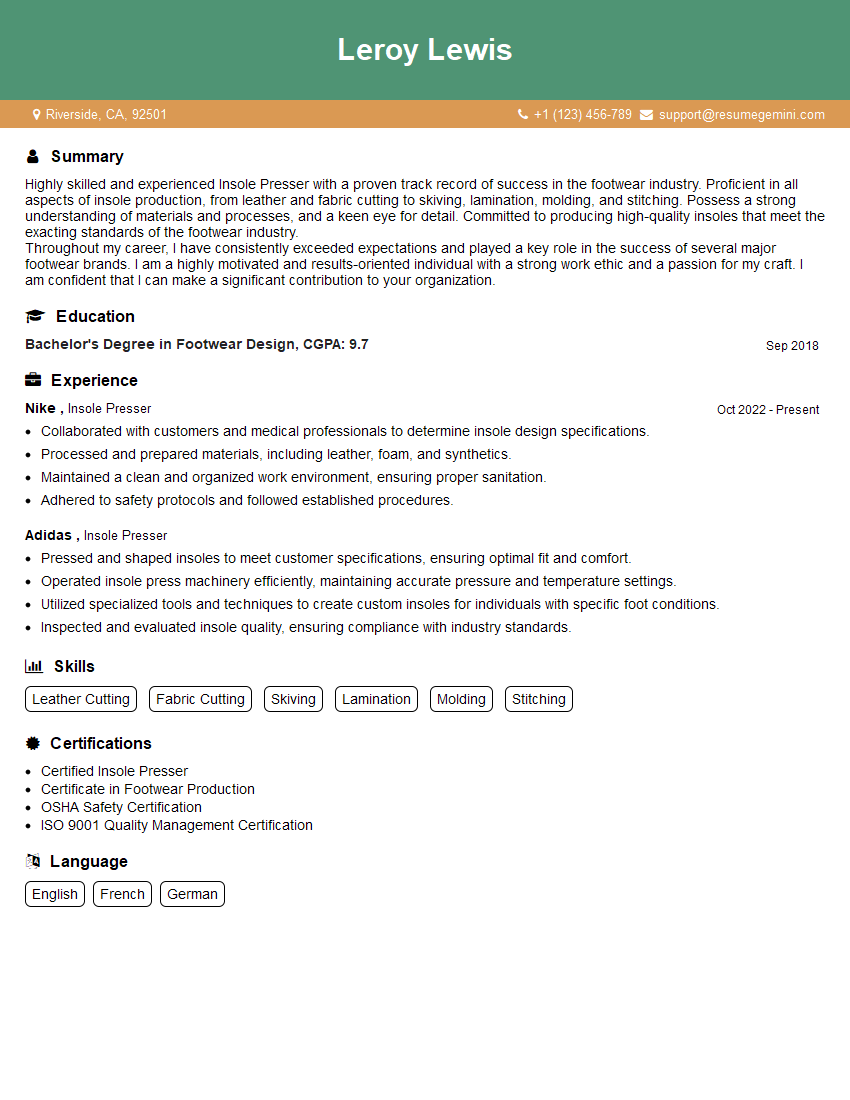

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Insole Presser

1. Describe the process of pressing insoles.

- Inspect the insoles to ensure they meet specifications and are free of defects.

- Position the insoles in the pressing machine, making sure they are properly aligned and centered.

- Apply pressure to the insoles using the appropriate platen and pressure settings.

- Maintain the pressure for the specified time or until the insoles are properly pressed.

- Remove the pressed insoles from the machine and inspect them for quality.

2. What are the different types of insoles and their unique pressing requirements?

- Leather insoles: Require high pressure and heat to mold and shape properly.

- Foam insoles: Require lower pressure and heat to avoid damaging the foam.

- Gel insoles: Require special platens to avoid damaging the gel.

- Composite insoles: May require a combination of pressure and heat settings depending on the materials used.

3. What are the common problems encountered during insole pressing and how do you resolve them?

- Wrinkles or creases: Caused by improper alignment or insufficient pressure. Adjust platen alignment and increase pressure.

- Bubbles or air pockets: Caused by trapped air. Reposition the insoles and repress with increased pressure.

- Insufficient adhesion: Caused by improper pressure or heat settings. Adjust settings accordingly and ensure the insoles are properly pressed.

- Deformation or damage: Caused by excessive pressure or heat. Reduce pressure or heat settings and inspect the insoles carefully before pressing.

4. What safety precautions should be taken when operating an insole pressing machine?

- Always wear appropriate safety gear, including gloves and safety glasses.

- Ensure the machine is properly grounded and maintained.

- Keep work area clean and free of debris.

- Follow all manufacturer’s instructions and safety guidelines.

- Never attempt to operate the machine if you are not properly trained.

5. How do you ensure that the pressed insoles meet quality standards?

- Inspect the insoles for any defects or imperfections.

- Check the dimensions and shape to ensure they meet specifications.

- Test the adherence of the insoles to the footwear.

- Obtain feedback from customers to identify any areas for improvement.

- Regularly calibrate and maintain the pressing machine to ensure accurate and consistent results.

6. What is the role of temperature control in insole pressing?

- Heat helps to soften and mold the insoles: Allowing them to conform to the shape of the footwear.

- Excessive heat can damage the insoles: So it is important to control the temperature carefully.

- Different materials have different temperature requirements: So it is important to use the appropriate settings for each type of insole.

7. How do you handle variations in insole thickness and density?

- Adjust the pressure and heat settings: Thicker insoles require higher pressure and heat, while thinner insoles require lower settings.

- Use different platens: Some platens are designed specifically for thicker or thinner insoles.

- Consider using a multi-stage pressing process: This can help to ensure even pressure distribution and prevent damage to the insoles.

8. What is your experience with different types of insole pressing machines?

- Manual machines: Require manual operation and offer limited control over pressure and heat.

- Semi-automatic machines: Offer more control over pressure and heat, but still require some manual operation.

- Automatic machines: Fully automated and offer precise control over all pressing parameters.

- Discuss your experience with each type of machine and highlight your strengths and weaknesses.

9. How do you optimize the efficiency of the insole pressing process?

- Properly maintain the machine: Regular maintenance can help to prevent breakdowns and ensure smooth operation.

- Use the correct settings for each type of insole: This can help to reduce pressing time and improve quality.

- Batch process insoles: Pressing multiple insoles at once can save time and increase productivity.

- Implement automation: Automated machines can significantly improve efficiency and reduce labor costs.

- Train operators properly: Well-trained operators can operate the machine efficiently and produce high-quality insoles.

10. What are your expectations for this role and how do you see yourself contributing to our team?

- Express enthusiasm for the role and the opportunity to contribute to the team.

- Highlight your skills and experience that are relevant to the job.

- Emphasize your commitment to quality and efficiency.

- Explain how your knowledge and expertise can benefit the team.

- Express your willingness to learn and grow within the organization.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Insole Presser.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Insole Presser‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

An Insole Presser is an integral part of the shoe manufacturing process, responsible for ensuring the precise fit and comfort of footwear through the expert pressing of insoles. Their responsibilities encompass:

1. Insole Preparation

Prior to pressing, the Insole Presser meticulously prepares insoles by checking for defects, removing excess materials, and making any necessary adjustments for proper fit.

2. Presser Operation

Using high-powered presses, the Insole Presser deftly shapes insoles according to specified patterns and dimensions. They employ precise pressure and temperature settings to achieve optimal adhesion and comfort.

3. Quality Control

Inspecting pressed insoles is crucial, and the Insole Presser meticulously checks each one for accuracy, ensuring that they meet the required standards and specifications.

4. Machine Maintenance

Maintaining and calibrating presses is essential for optimal performance. The Insole Presser diligently follows maintenance schedules, ensuring the smooth operation and longevity of equipment.

Interview Tips

Preparing thoroughly for an Insole Presser interview can significantly enhance your chances of success. Here are some effective tips:

1. Research the Role

Familiarize yourself with the specific responsibilities and requirements of the Insole Presser role within the footwear industry. Learn about the company’s products and processes to demonstrate your interest and understanding.

2. Highlight Relevant Experience

Showcase your skills and experience that align with the key job responsibilities. Emphasize your attention to detail, precision in measurements, and ability to work in a fast-paced manufacturing environment.

3. Prepare Industry-Specific Questions

Demonstrate your knowledge of the industry by asking insightful questions related to footwear manufacturing techniques, material properties, or quality control standards.

4. Practice Your Presentation

Rehearse your responses to common interview questions to build confidence and deliver your answers clearly and effectively. Highlight your strengths and how they contribute to your ability to excel as an Insole Presser.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Insole Presser interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!