Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Lining Caser position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

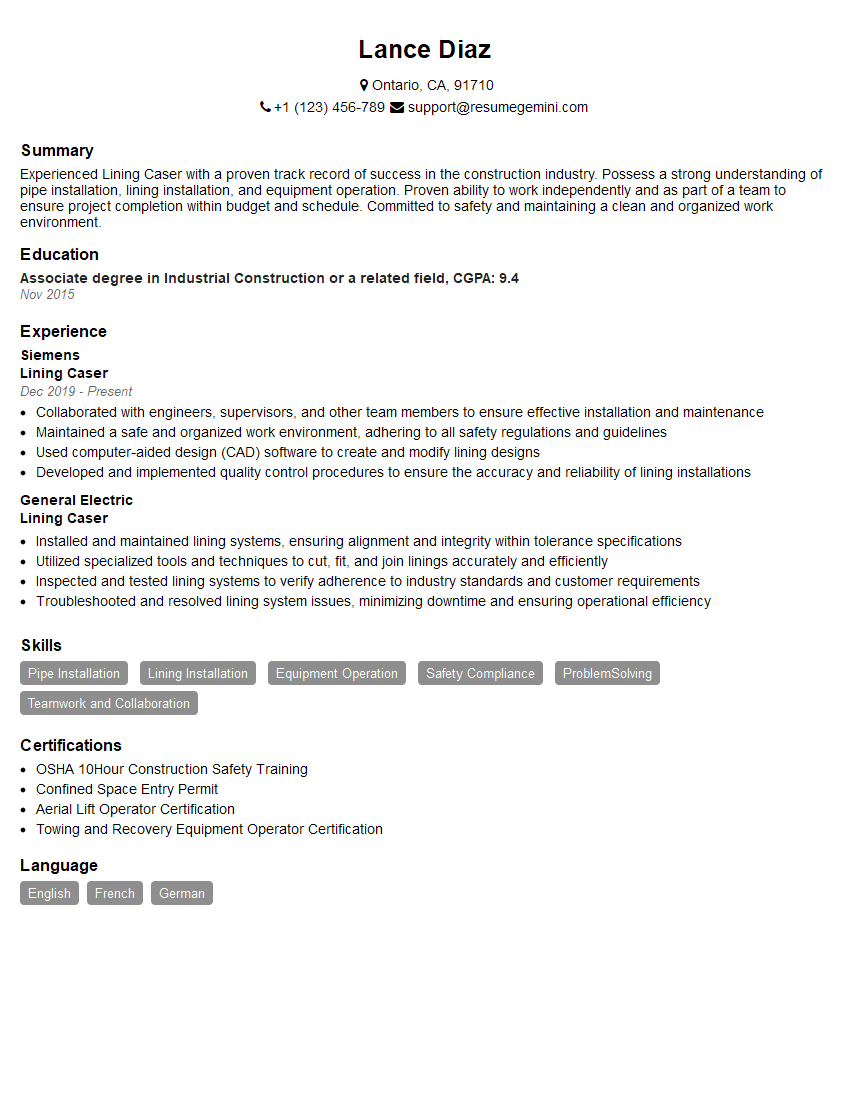

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Lining Caser

1. Can you describe the end-to-end process of lining a casing?

- Prepare the casing by cleaning and inspecting it.

- Apply a layer of cement to the inside of the casing.

- Insert the casing into the wellbore and run it to the desired depth.

- Circulate drilling fluid through the casing to remove any remaining cement.

- Set the casing by pumping cement into the annulus between the casing and the wellbore.

- Pressure test the casing to ensure it is properly set.

2. What are the different types of casing liners?

Types of Casing Liners

- Conductor casing: The first casing string run into a wellbore, used to protect the wellbore from collapse during drilling.

- Surface casing: The second casing string run into a wellbore, used to protect the wellbore from fluids and gases encountered during drilling.

- Intermediate casing: Casing strings run into a wellbore to protect it from fluids and gases encountered during drilling, and to isolate different zones of the wellbore.

- Production casing: The final casing string run into a wellbore, used to protect the wellbore from fluids and gases produced from the reservoir.

- Liner: A casing string that is run into a wellbore to protect it from fluids and gases encountered during drilling or production, and to isolate different zones of the wellbore.

3. What are the factors that affect the design of a casing liner?

- The depth of the wellbore

- The diameter of the wellbore

- The type of drilling fluid being used

- The pressure and temperature of the fluids and gases in the wellbore

- The presence of any corrosive fluids or gases in the wellbore

4. What are the different methods of lining a casing?

- Lining hanger method: A liner hanger is used to suspend the liner in the wellbore and to seal the annulus between the liner and the casing.

- Slip-and-seal method: Slips are used to hold the liner in the wellbore and to seal the annulus between the liner and the casing.

- Tie-back method: The liner is tied back to the casing using a tie-back assembly.

5. What are the advantages and disadvantages of lining a casing?

Advantages

- Protects the wellbore from fluids and gases

- Isolates different zones of the wellbore

- Provides structural support for the wellbore

- Improves wellbore stability

- Can be used to repair a damaged casing

Disadvantages

- Can be expensive and time-consuming to install

- Can reduce the diameter of the wellbore

- Can restrict the flow of fluids and gases in the wellbore

6. What are the different types of casing liners used in oil and gas wells?

- Conductor liners: Used to protect the wellbore from collapse during drilling.

- Surface liners: Used to protect the wellbore from fluids and gases encountered during drilling.

- Intermediate liners: Used to protect the wellbore from fluids and gases encountered during drilling, and to isolate different zones of the wellbore.

- Production liners: Used to protect the wellbore from fluids and gases produced from the reservoir.

7. What are the factors that affect the selection of a casing liner?

- The depth of the wellbore

- The diameter of the wellbore

- The type of drilling fluid being used

- The pressure and temperature of the fluids and gases in the wellbore

- The presence of any corrosive fluids or gases in the wellbore

8. What are the different types of casing liner materials?

- Carbon steel: The most common type of casing liner material, used in a wide variety of applications.

- Alloy steel: Used in applications where higher strength or corrosion resistance is required.

- Stainless steel: Used in applications where high corrosion resistance is required.

- Titanium: Used in applications where high strength and corrosion resistance are required.

9. What are the different types of casing liner connections?

- Threaded connections: Use threads to connect the liner to the casing.

- Coupled connections: Use a coupling to connect the liner to the casing.

- Welded connections: Use welding to connect the liner to the casing.

10. What are the different types of casing liner accessories?

- Liner hangers: Used to suspend the liner in the wellbore and to seal the annulus between the liner and the casing.

- Slips: Used to hold the liner in the wellbore and to seal the annulus between the liner and the casing.

- Tie-back assemblies: Used to tie the liner back to the casing.

- Centralizers: Used to center the liner in the wellbore.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Lining Caser.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Lining Caser‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

As a Lining Caser, you will be responsible for the effective and efficient installation of linings in various equipment and structures.

1. Lining Installation and Maintenance

You will plan and undertake the precise installation of linings, including measuring and fitting, adhering to established specifications. Perform regular inspections and maintenance to ensure the integrity of installed linings.

- Install and repair linings in tanks, pipes, and other equipment.

- Inspect linings for defects and perform necessary repairs.

2. Material Handling and Preparation

You will handle and prepare various lining materials, such as rubber, plastic, and metal, while accurately following safety protocols. Adhere to established procedures for mixing, applying, and curing materials.

- Mix and apply lining materials according to specifications.

- Prepare surfaces for lining installation.

3. Equipment Operation and Maintenance

You will operate and maintain equipment used in lining installation, including sprayers, rollers, and curing ovens. Perform routine maintenance and ensure that all equipment is in optimal working condition.

- Operate lining equipment safely and efficiently.

- Maintain and repair lining equipment.

4. Safety and Compliance

Prioritizing safety, you will adhere to all established safety regulations and guidelines while working with potentially hazardous materials and equipment. Maintain a clean and organized work area, ensuring compliance with environmental standards.

- Follow all safety regulations and procedures.

- Maintain a clean and organized work area.

Interview Tips

To enhance your interview performance and increase your chances of success, consider the following tips:

1. Research the Company and Role

Before the interview, thoroughly research the company and the specific Lining Caser role. Understand their industry, values, and recent developments. This knowledge will demonstrate your interest and preparation, allowing you to ask informed questions during the interview.

- Visit the company’s website and social media pages.

- Read industry news and articles.

- Prepare questions to ask the interviewer about the company and role.

2. Highlight Relevant Skills and Experience

During the interview, emphasize your skills and experience that directly align with the Lining Caser job responsibilities. Quantify your accomplishments and provide specific examples to showcase your abilities in lining installation, material handling, and equipment operation.

- Share examples of complex lining projects you have successfully completed.

- Describe your experience in handling and applying different lining materials.

- Explain how you ensure the safety and quality of your work.

3. Demonstrate Safety Awareness

As a Lining Caser, safety is paramount. In the interview, highlight your strong safety awareness and adherence to established protocols. Describe your experience in working with hazardous materials and equipment, and emphasize your commitment to maintaining a safe work environment.

- Explain your understanding of the safety regulations and guidelines relevant to lining installation.

- Share examples of how you have identified and mitigated safety risks on the job.

- Describe your experience in using personal protective equipment and following safety procedures.

4. Ask Thoughtful Questions

Towards the end of the interview, asking thoughtful questions can leave a positive impression. This demonstrates your engagement, interest, and desire to contribute to the organization. Prepare questions about the company’s goals, the team you would be joining, and opportunities for professional development.

- Ask about the company’s plans for future growth and expansion.

- Inquire about the training and support provided to new employees.

- Express your interest in any specific projects or initiatives that align with your skills and interests.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Lining Caser role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.