Are you gearing up for a career in Lining Cleaner? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Lining Cleaner and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

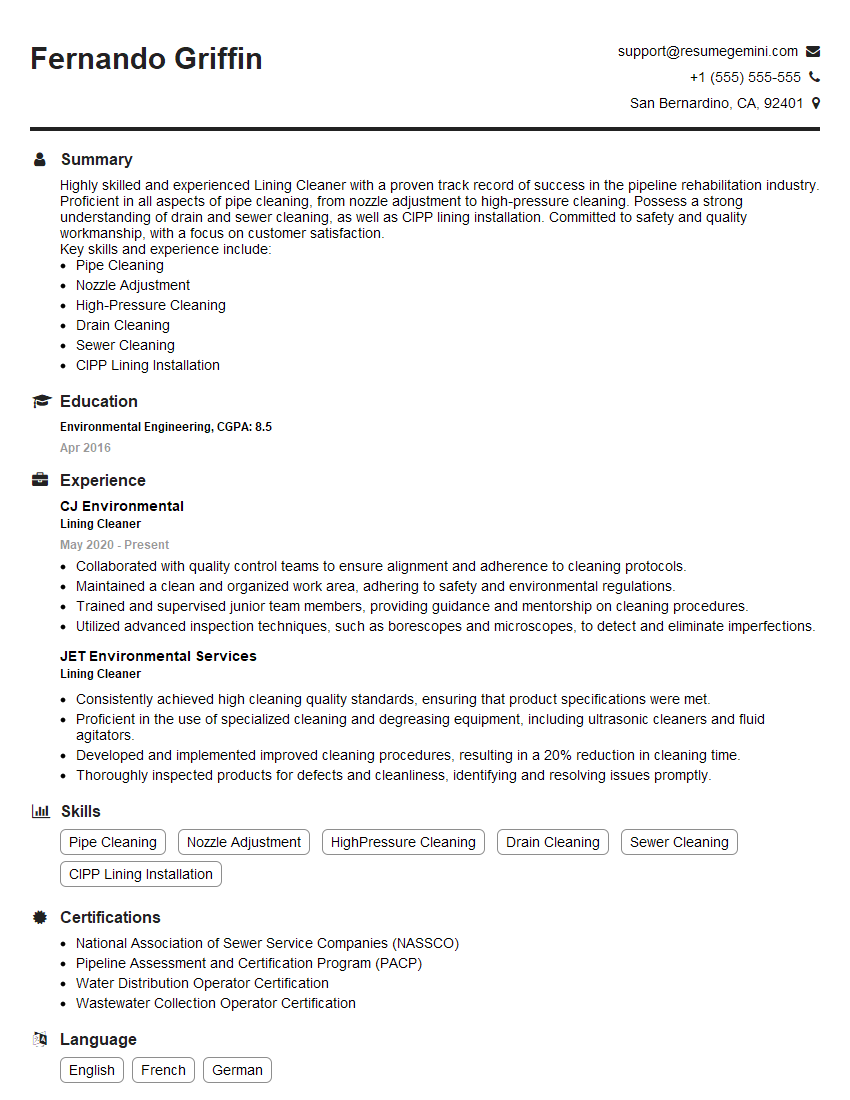

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Lining Cleaner

1. What is the process of lining cleaning?

The process of lining cleaning involves removing deposits and contaminants from the interior surface of a pipe or vessel using specialized equipment and techniques.

- Inspect the lining to identify the type and extent of contamination.

- Select the appropriate cleaning method based on the nature of the contaminants and the material of the lining.

- Prepare the cleaning equipment and chemicals.

- Apply the cleaning solution to the lining surface and allow it to dwell for the required time.

- Remove the loosened contaminants using high-pressure water jetting, mechanical brushes, or other cleaning tools.

- Rinse the lining thoroughly with clean water to remove any residual cleaning solution or contaminants.

- Inspect the lining to ensure that it is clean and free of defects.

2. What are the different types of lining cleaning methods?

Chemical Cleaning

- Uses specialized chemicals to dissolve and remove contaminants.

- Suitable for removing organic deposits, such as grease, oil, and scale.

Mechanical Cleaning

- Employs mechanical tools, such as brushes, scrapers, and water jets, to physically remove contaminants.

- Effective for removing hard deposits, such as rust, corrosion, and mineral buildup.

Abrasive Cleaning

- Uses abrasive materials, such as sand or grit, to blast away contaminants.

- Suitable for removing thick or heavily adhered deposits.

3. What equipment is used for lining cleaning?

- High-pressure water jetting equipment

- Mechanical brushes and scrapers

- Chemical cleaning solutions

- Abrasive blasting equipment

- Inspection cameras and lighting

- Safety gear, such as respirators and gloves

4. What safety precautions should be taken during lining cleaning?

- Wear appropriate personal protective equipment (PPE), including a respirator, gloves, eye protection, and coveralls.

- Ventilate the area to remove potentially hazardous fumes or vapors.

- Handle chemicals safely and according to the manufacturer’s instructions.

- Follow proper lockout/tagout procedures to prevent accidental equipment activation.

- Inspect equipment regularly to ensure it is in good working order.

- Be aware of potential trip hazards and slippery surfaces.

5. How do you determine the effectiveness of a lining cleaning process?

- Inspect the lining before and after cleaning to compare the level of cleanliness.

- Perform chemical or physical tests to measure the removal of specific contaminants.

- Monitor the performance of the lining after cleaning to ensure that it is functioning correctly.

- Maintain records of cleaning procedures and results for future reference.

6. What are the common challenges encountered during lining cleaning?

- Difficult-to-reach areas or complex geometries.

- Thick or stubborn contaminants that require specialized cleaning methods.

- Safety hazards associated with working in confined spaces or with hazardous chemicals.

- Limited access to the lining or difficulties in isolating it from the process.

- Time constraints or production schedules that impact the cleaning process.

7. Describe your experience with cleaning different types of linings.

I have extensive experience in cleaning various types of linings, including epoxy, polyurethane, polyurea, and fiberglass. I am familiar with the different properties and cleaning requirements of each material.

- Epoxy linings: Chemical cleaning with specialized solvents and alkaline solutions.

- Polyurethane linings: Mechanical cleaning using brushes and high-pressure water jets.

- Polyurea linings: Abrasive cleaning or chemical cleaning with strong solvents.

- Fiberglass linings: Mechanical cleaning with brushes and water jets, avoiding abrasive methods.

8. What is the importance of proper lining cleaning?

- Maintains the integrity and functionality of the lining.

- Prevents premature failure or degradation of the lining.

- Improves the efficiency and performance of the process.

- Ensures compliance with industry standards and regulations.

- Reduces the risk of contamination or product defects.

9. How do you stay updated on the latest lining cleaning technologies and techniques?

- Attend industry conferences and workshops.

- Read technical journals and articles.

- Consult with equipment manufacturers and chemical suppliers.

- Participate in online forums and discussions.

- Seek continuing education opportunities.

10. How do you ensure the quality of your lining cleaning services?

- Follow standardized cleaning procedures and checklists.

- Use high-quality equipment and chemicals.

- Inspect linings thoroughly before and after cleaning.

- Document all cleaning activities and results.

- Seek feedback from clients and continually improve processes.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Lining Cleaner.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Lining Cleaner‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Lining Cleaners are responsible for cleaning, maintaining, and repairing the linings of various types of equipment and structures. They work in a variety of industries, including manufacturing, construction, and transportation.

1. Cleaning and Maintaining Linings

Lining Cleaners are responsible for cleaning and maintaining the linings of equipment and structures to prevent corrosion, wear, and other damage. They use a variety of cleaning methods, including manual cleaning, power washing, and chemical cleaning.

- Manually clean linings using brushes, rags, and cleaning solutions.

- Power wash linings to remove dirt and debris.

- Apply chemical cleaners to linings to dissolve and remove contaminants.

2. Repairing Linings

Lining Cleaners are also responsible for repairing damaged linings. They use a variety of repair methods, including welding, patching, and relining.

- Weld damaged linings to fill holes and cracks.

- Patch damaged linings using materials such as fiberglass and metal.

- Reline damaged linings by installing a new lining over the old lining.

3. Inspecting Linings

Lining Cleaners are responsible for inspecting linings to identify any damage or wear. They use a variety of inspection methods, including visual inspection, ultrasonic testing, and radiographic testing.

- Visually inspect linings for holes, cracks, and other damage.

- Use ultrasonic testing to detect hidden damage in linings.

- Use radiographic testing to create images of linings to identify damage.

4. Other Duties

Lining Cleaners may also be responsible for performing other duties, such as:

- Maintaining records of cleaning, repair, and inspection work.

- Ordering and stocking cleaning and repair supplies.

- Training new Lining Cleaners.

Interview Tips

Preparing for an interview can be a daunting task, but there are a few things you can do to increase your chances of success.

1. Research the company and the position

Before you go on an interview, it’s important to do your research and learn as much as you can about the company and the position you’re applying for. This will help you answer questions intelligently and show the interviewer that you’re genuinely interested in the job.

- Visit the company’s website to learn about their history, mission, and values.

- Read articles about the company and the industry to get a better understanding of the business.

- Look at the job description to identify the key responsibilities and qualifications.

2. Practice your answers to common interview questions

There are a few common interview questions that you’re likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It’s a good idea to practice your answers to these questions in advance so that you can deliver them confidently and concisely.

- Write out your answers to common interview questions and practice saying them aloud.

- Ask a friend or family member to conduct a mock interview with you.

- Record yourself answering interview questions and watch the recording to identify areas for improvement.

3. Dress professionally and arrive on time

First impressions matter, so it’s important to dress professionally and arrive on time for your interview. This shows the interviewer that you’re respectful of their time and that you’re taking the interview seriously.

- Dress in clean, pressed clothing that is appropriate for the business environment.

- Arrive for your interview a few minutes early so that you have time to relax and collect your thoughts.

4. Be yourself and be enthusiastic

The most important thing is to be yourself and be enthusiastic about the job. The interviewer wants to get to know the real you, so don’t try to be someone you’re not. Be confident in your abilities and show the interviewer why you’re the best person for the job.

- Answer questions honestly and don’t try to hide your weaknesses.

- Be passionate about the job and show the interviewer that you’re eager to learn and grow.

- Be positive and upbeat, even if you’re nervous.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Lining Cleaner, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Lining Cleaner positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.