Are you gearing up for a career in Machine Sewer? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Machine Sewer and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

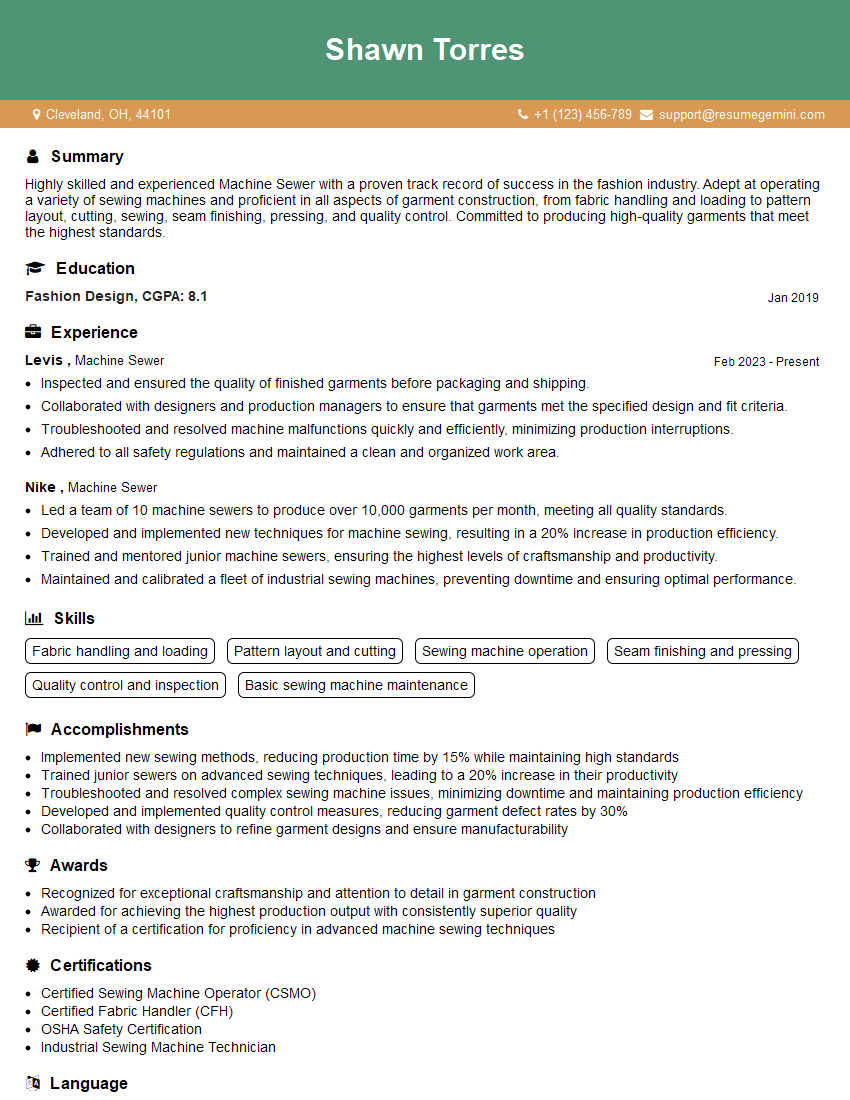

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Machine Sewer

1. What are the different types of sewing machines used in the industry?

In the industry, there are various types of sewing machines used for different purposes, including:

- Lockstitch machines: These are the most common type of sewing machine and are used for a wide variety of tasks. They create a stitch that is secure and durable, making them ideal for seams in garments, upholstery, and other products.

- Overlock machines: These machines are used to create a finished edge on fabric. They cut the fabric as they sew, and the stitch that they create helps to prevent fraying.

- Coverstitch machines: These machines are used to create a decorative stitch on the edge of fabric. They can be used to add a touch of style to garments, swimwear, and other products.

- Bar tack machines: These machines are used to create a strong and durable stitch that is often used to reinforce areas of a garment that are subject to stress, such as the crotch of pants.

2. How do you determine the correct tension for the thread?

The correct tension for the thread is crucial for the quality of the stitch. If the tension is too tight, the thread can break. If the tension is too loose, the stitch will be loose and weak. The correct tension can be determined by:

- Checking the manufacturer’s recommendations: The manufacturer of the sewing machine will provide recommendations for the correct thread tension. These recommendations can be found in the machine’s manual.

- Experimenting: You can also experiment with different thread tensions to find the one that works best for your particular project.

3. What are the different types of stitches used in sewing?

There are many different types of stitches used in sewing, each with its own unique purpose. Some of the most common types of stitches include:

- Straight stitch: This is the most basic type of stitch and is used for a wide variety of tasks. It is a strong and durable stitch that can be used for seams, hems, and other purposes.

- Zigzag stitch: This stitch is used to create a finished edge on fabric. It is a strong and durable stitch that also helps to prevent fraying.

- Overlock stitch: This stitch is used to create a decorative edge on fabric. It is a strong and durable stitch that can be used to add a touch of style to garments and other products.

- Bar tack stitch: This stitch is used to create a strong and durable stitch that is often used to reinforce areas of a garment that are subject to stress, such as the crotch of pants.

4. What are the different types of fabric used in sewing?

There are many different types of fabric used in sewing, each with its own unique properties. Some of the most common types of fabric include:

- Cotton: Cotton is a natural fiber that is soft, breathable, and easy to care for. It is a good choice for a wide variety of sewing projects, including garments, home décor, and quilts.

- Polyester: Polyester is a synthetic fiber that is strong, durable, and wrinkle-resistant. It is a good choice for outdoor fabrics, sportswear, and other applications where durability is important.

- Nylon: Nylon is a synthetic fiber that is strong, durable, and water-resistant. It is a good choice for outerwear, swimwear, and other applications where water resistance is important.

- Silk: Silk is a natural fiber that is luxurious, soft, and drapes beautifully. It is a good choice for special occasion garments, lingerie, and other delicate items.

5. What is the difference between a serger and a sewing machine?

A serger is a type of sewing machine that is used to create a finished edge on fabric. It cuts the fabric as it sews, and the stitch that it creates helps to prevent fraying. A sewing machine, on the other hand, is used to sew seams and other types of stitches. It does not cut the fabric as it sews, and the stitch that it creates is not as strong as the stitch created by a serger.

6. What are the safety precautions that should be taken when using a sewing machine?

When using a sewing machine, it is important to take the following safety precautions:

- Always keep your hands away from the needle: The needle can move very quickly and can easily puncture your skin.

- Never reach into the machine while it is running: You could get your fingers caught in the moving parts.

- Always unplug the machine before changing the needle or thread: This will help to prevent accidental injury.

- Keep the machine clean and well-maintained: This will help to prevent accidents and ensure that the machine operates properly.

7. What are the different types of sewing machine needles?

There are many different types of sewing machine needles available, each designed for a specific purpose. Some of the most common types of needles include:

- Universal needles: These needles are suitable for a wide variety of fabrics and are a good choice for general sewing projects.

- Sharp needles: These needles are used for delicate fabrics, such as silk and chiffon. They have a sharp point that helps to prevent snagging.

- Ballpoint needles: These needles are used for knit fabrics. They have a rounded point that helps to prevent damage to the fabric.

- Stretch needles: These needles are used for fabrics that stretch, such as swimwear and activewear. They have a special groove that helps to prevent the fabric from puckering.

8. How do you troubleshoot a sewing machine?

If your sewing machine is not working properly, there are a few things you can do to troubleshoot the problem. Here are a few of the most common problems and solutions:

- The machine won’t start: Check to make sure that the machine is plugged in and that the power switch is turned on. Also, check the thread tension to make sure that it is not too tight.

- The machine is making a strange noise: This could be caused by a number of things, such as a loose belt, a dirty machine, or a damaged needle. Check all of these things and make the necessary repairs.

- The stitches are uneven: This could be caused by a number of things, such as the incorrect thread tension, a damaged needle, or a problem with the machine’s timing. Check all of these things and make the necessary repairs.

9. What are the different types of sewing machine feet?

There are many different types of sewing machine feet available, each designed for a specific purpose. Some of the most common types of feet include:

- Standard presser foot: This is the most basic type of presser foot and is used for a wide variety of sewing projects.

- Zipper foot: This foot is used for sewing zippers. It has a narrow toe that helps to keep the zipper in place.

- Buttonhole foot: This foot is used for sewing buttonholes. It has a special slot that helps to create the buttonhole.

- Blind hem foot: This foot is used for sewing blind hems. It has a special plate that helps to hide the stitches on the right side of the fabric.

10. What is the difference between a seam allowance and a hem allowance?

A seam allowance is the amount of fabric that is added to a seam to allow for fraying and finishing. A hem allowance is the amount of fabric that is added to a hem to allow for folding and finishing. The seam allowance is typically 5/8 inch wide, while the hem allowance is typically 1 inch wide.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Machine Sewer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Machine Sewer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Machine Sewers are responsible for operating and maintaining industrial sewing machines to create and repair clothing and other textile products. They must be able to follow instructions carefully, work independently, and meet production quotas.

1. Operate industrial sewing machines

Machine Sewers must be able to operate a variety of industrial sewing machines, including single-needle, double-needle, and overlock machines. They must be able to adjust the machines to sew different types of fabrics and to create different types of seams.

- Adjust the machine to sew different types of fabrics

- Create different types of seams

- Troubleshoot and repair machine problems

2. Follow instructions

Machine Sewers must be able to follow instructions carefully in order to produce high-quality products. They must be able to read and understand sewing patterns and to follow instructions from supervisors and other team members.

- Read and understand sewing patterns

- Follow instructions from supervisors and other team members

- Produce high-quality products

3. Work independently

Machine Sewers often work independently, so they must be able to manage their time and resources effectively. They must be able to set up and operate their machines, and they must be able to troubleshoot and repair problems as they arise.

- Set up and operate their machines

- Troubleshoot and repair problems

- Manage their time and resources effectively

4. Meet production quotas

Machine Sewers must be able to meet production quotas in order to help their company meet customer demand. They must be able to work quickly and accurately, and they must be able to maintain a high level of quality.

- Work quickly and accurately

- Maintain a high level of quality

- Meet production quotas

Interview Tips

Preparing for a Machine Sewer interview can be daunting, but there are a few things you can do to increase your chances of success. Here are a few tips:

1. Research the company and the position

Before you go to your interview, take some time to research the company and the position you are applying for. This will help you to understand the company’s culture and values, and it will also help you to prepare for the questions that you are likely to be asked.

- Visit the company’s website

- Read about the company’s history, mission, and values

- Learn about the specific position you are applying for

2. Practice answering common interview questions

There are a few common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It is helpful to practice answering these questions in advance so that you can deliver your answers confidently and clearly.

- Use the STAR method to answer behavioral questions

- Prepare examples of your work that demonstrate your skills and experience

- Be prepared to talk about your strengths and weaknesses

3. Dress professionally and arrive on time

First impressions matter, so it is important to dress professionally and arrive on time for your interview. This shows the interviewer that you are serious about the position and that you respect their time.

- Wear clean, pressed clothes

- Arrive for your interview on time

- Make eye contact and shake the interviewer’s hand firmly

4. Be yourself and be confident

The most important thing is to be yourself and to be confident in your abilities. The interviewer wants to get to know the real you, so don’t try to be someone you’re not. Just relax, be yourself, and let your personality shine through.

- Be honest about your skills and experience

- Be confident in your abilities

- Let your personality shine through

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Machine Sewer interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!