Feeling lost in a sea of interview questions? Landed that dream interview for Pinking Machine Operator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Pinking Machine Operator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

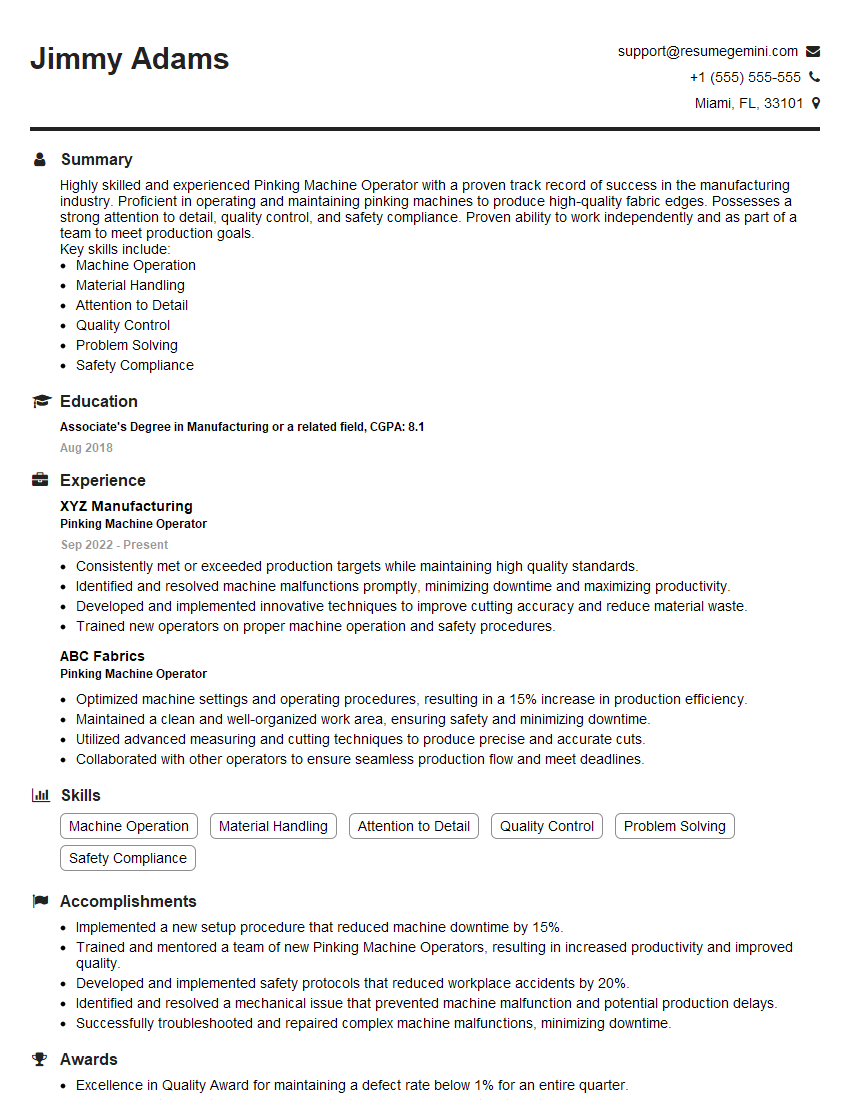

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Pinking Machine Operator

1. What is the process of pinking?

Pinking is a process of cutting decorative or functional edges on fabric, ribbon, or paper. It is done by using a pinking machine, which has a blade that is specially designed to create a zigzag or scalloped edge. Pinking can be used for a variety of purposes, such as reducing fraying, creating decorative edges, or adding a playful touch to a project.

2. What are the different types of pinking machines?

Industrial Pinkers

- High-volume production environments

- Handle heavy-duty materials

- Automated or semi-automated

Portable Pinkers

- Small-scale projects or on-site work

- Lightweight and easy to transport

Manual Pinkers

- Hand-operated devices

- Suitable for small projects or delicate fabrics

3. What are the key features to consider when selecting a pinking machine?

Key features to consider when selecting a pinking machine include:

- Types of materials to be cut

- Desired edge shape and width

- Machine capacity and speed

- Ease of operation and maintenance

- Cost and availability of replacement blades

4. How do you maintain a pinking machine?

Proper maintenance is crucial to ensure the optimal performance and longevity of a pinking machine. Regular maintenance tasks may include:

- Cleaning the machine head and blade to remove fabric debris

- Lubricating moving parts as per manufacturer’s instructions

- Inspecting the blade for sharpness and replacing it when necessary

- Checking tension settings to ensure proper fabric feeding

5. What safety precautions should be taken when operating a pinking machine?

Safety precautions for operating a pinking machine include:

- Wearing appropriate safety gear, such as gloves and safety glasses

- Ensuring the machine is properly grounded to prevent electrical hazards

- Keeping hands and fingers away from the blade while operating

- Never reaching into the machine while it is running

6. What are the common problems that can occur with pinking machines and how can they be resolved?

Blade Issues

- Dull or damaged blade: Replace the blade

- Misaligned blade: Adjust the blade alignment

Fabric Feeding Issues

- Improper tension: Check and adjust the tension settings

- Fabric slippage: Use a non-slip surface or feed the fabric more slowly

Motor Problems

- Overheating: Allow the machine to cool down or check for ventilation issues

- Electrical fault: Refer to a qualified electrician

7. How do you set up a pinking machine for different types of fabric?

To set up a pinking machine for different types of fabric, it is important to:

- Adjust the blade height: Set the blade height according to the thickness of the fabric

- Set the stitch length: Choose a stitch length that is appropriate for the fabric weight and desired edge finish

- Adjust the tension: Fine-tune the tension to ensure proper fabric feeding and edge quality

8. How do you troubleshoot quality issues with pinked edges?

Uneven or ragged edges

- Check the blade sharpness and alignment

- Adjust the tension settings

- Ensure the fabric is fed evenly

Skipped stitches

- Clean the machine head and blade

- Check the needle and replace if necessary

- Adjust the stitch length and tension

Puckering or gathering

- Reduce the stitch length

- Use a lighter-weight fabric or reduce the number of layers being cut

- Check the tension settings

9. How do you ensure the safety of others when operating a pinking machine?

Ensuring the safety of others when operating a pinking machine includes:

- Keeping the work area clear of obstacles and debris

- Informing others about the hazards of the machine and its operation

- Never leaving the machine unattended while it is running

- Storing the machine properly when not in use

10. What are the different applications of pinking machines in various industries?

Pinking machines find applications in a wide range of industries, including:

Textile and Garment Manufacturing

- Creating decorative edges on clothing, curtains, and other textiles

- Reducing fraying on seams and hems

Paper Products

- Creating decorative edges on invitations, greeting cards, and other paper items

- Perforating paper for easy tearing or binding

Automotive and Aerospace

- Cutting and shaping insulation materials

- Creating lightweight and durable components

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Pinking Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Pinking Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Pinking Machine Operators are responsible for the operation and maintenance of pinking machines, which are used to create decorative edges on fabrics. Key job responsibilities include:

1. Machine Operation

Setting up and operating pinking machines to create decorative edges on fabrics.

- Adjusting machine settings for different fabrics and patterns.

- Monitoring machine operation and making adjustments as needed.

2. Material Handling

Loading and unloading fabrics into and out of the machine.

- Inspecting fabrics for defects before and after processing.

- Ensuring that fabrics are fed into the machine correctly.

3. Quality Control

Inspecting finished products for quality and accuracy.

- Identifying and correcting any defects in the finished product.

- Maintaining quality standards throughout the production process.

4. Maintenance

Performing basic maintenance on pinking machines.

- Cleaning and lubricating machines regularly.

- Making minor repairs and adjustments to machines.

Interview Tips

To ace the interview for a Pinking Machine Operator position, it is important to highlight your skills and experience in the key job responsibilities. Here are some tips and hacks to help you prepare for the interview:

1. Research the Company and the Position

Learn about the company’s history, products, and services. Research the specific job responsibilities and requirements for the Pinking Machine Operator position.

- Visit the company website and read the job description carefully.

- Look for news articles and online reviews to learn more about the company’s culture and reputation.

2. Practice Your Answers to Common Interview Questions

Prepare for questions about your skills, experience, and qualifications. Practice your answers to common interview questions, such as:

- “Tell me about your experience operating pinking machines.”

- “How do you ensure the quality of your work?”

- “What are some common problems that you have encountered while operating pinking machines?”

3. Highlight Your Skills and Experience

Emphasize your skills and experience that are relevant to the job. Use specific examples to demonstrate your abilities in machine operation, material handling, quality control, and maintenance.

- Quantify your accomplishments whenever possible. For example, you could say, “I increased production by 10% by implementing a new method for loading fabrics into the machine.”

- Use the STAR method (Situation, Task, Action, Result) to structure your answers. This will help you provide clear and concise examples of your work.

4. Be Prepared to Ask Questions

Asking questions at the end of the interview shows that you are interested in the position and the company. It also gives you an opportunity to learn more about the job and the company’s expectations.

- Prepare a few thoughtful questions about the company, the position, or the industry.

- Don’t be afraid to ask for clarification if you don’t understand something.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Pinking Machine Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.