Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Seamer Operator interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Seamer Operator so you can tailor your answers to impress potential employers.

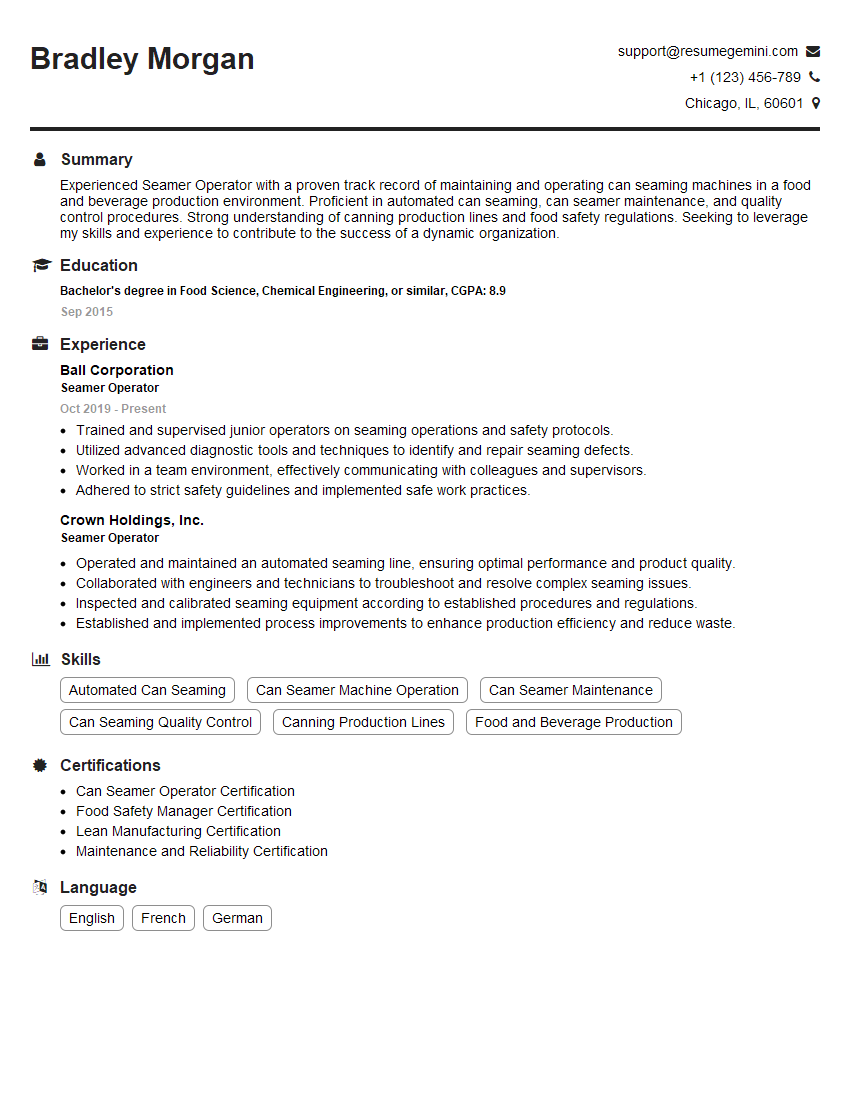

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Seamer Operator

1. What are the different types of seaming machines and their applications?

- Single Needle Seaming Machine: Used for general purpose seaming of light to medium weight fabrics.

- Double Needle Seaming Machine: Used for seaming heavy weight fabrics or for creating decorative stitching.

- Overlock Seaming Machine: Used for finishing raw edges of fabric to prevent fraying.

- Flatlock Seaming Machine: Used for creating a flat and durable seam on knit fabrics.

- Coverstitch Seaming Machine: Used for creating a clean and professional-looking hem on knit fabrics.

2. What are the key factors to consider when selecting a seaming thread?

- Fiber Content: Natural (e.g., cotton, linen) or synthetic (e.g., nylon, polyester).

- Thread Count: Higher thread count indicates finer and stronger thread.

- Thread Ply: Number of strands twisted together (e.g., 2-ply, 3-ply).

- Tensile Strength: Resistance to breaking under tension.

- Abrasion Resistance: Resistance to wear and tear.

3. How do you ensure proper tension in the seaming process?

- Check the tension settings on the seaming machine.

- Use a tension gauge to measure the thread tension.

- Test the tension by sewing on scrap fabric and adjusting as needed.

- Monitor the stitch quality throughout the sewing process to detect any changes in tension.

4. What are some common defects in seaming and how can they be prevented?

- Broken Seams: Caused by incorrect tension, dull needles, or poor thread quality; prevent by using proper tension, sharp needles, and durable thread.

- Puckering: Caused by uneven fabric feeding or tight stitching; prevent by ensuring consistent fabric feed and adjusting stitch length and tension.

- Skipped Stitches: Caused by dull needles, poor thread quality, or incorrect needle size; prevent by using sharp needles, high-quality thread, and appropriate needle size.

- Needle Breakage: Caused by using blunt or bent needles, or sewing through hard objects; prevent by using sharp needles and avoiding sewing over zippers or other hard items.

5. How do you troubleshoot a seaming machine that is not functioning properly?

- Check the power source and connections.

- Inspect the needle for damage or dullness.

- Clean the machine, especially the thread path and tension discs.

- Check the thread tension settings and adjust as needed.

- Lubricate the machine according to the manufacturer’s instructions.

6. How do you maintain a seaming machine for optimal performance?

- Regular Cleaning: Remove lint and thread scraps from the machine.

- Lubrication: Oil the machine regularly to reduce friction and wear.

- Needle Replacement: Replace dull or damaged needles regularly.

- Tension Adjustment: Check and adjust thread tension as needed.

- Foot Pedal Inspection: Ensure the foot pedal is functioning properly and adjust tension if necessary.

7. What safety precautions are important to follow when operating a seaming machine?

- Wear appropriate safety gear such as gloves and safety glasses.

- Keep hands and fingers away from the needle.

- Use a guard or safety shield when operating the machine.

- Unplug the machine before performing maintenance or cleaning.

8. Can you describe the different stitch types used in seaming and their applications?

- Straight Stitch: Basic stitch used for general purpose seaming.

- Zigzag Stitch: Used to finish raw edges and prevent fraying.

- Overlock Stitch: Used to create a durable and stretchy seam on knit fabrics.

- Blind Hem Stitch: Used to create an invisible hem on garments.

- Topstitch Stitch: Used to create a decorative and durable seam on garments.

9. What is the importance of seam allowance in seaming?

- Prevents fraying and unraveling of fabric edges.

- Provides room for seam finishing techniques such as overcasting or serging.

- Allows for adjustments and alterations if necessary.

10. Can you explain the principles of differential feed in a seaming machine?

- Differential feed system consists of two feed dogs that move at different speeds.

- Allows for precise control of fabric feeding and gathering.

- Used for creating ruffles, shirring, and other decorative effects.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Seamer Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Seamer Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Seamer Operator plays a crucial role in the production line, ensuring the seamless and efficient packaging of products in cans, bottles, or pouches. Their responsibilities encompass various aspects of the seaming process, including:

1. Operation and Maintenance of Seaming Equipment

Seamer Operators are responsible for the skillful operation of seaming machines, which create hermetic seals on containers. They ensure the machines are calibrated correctly, perform routine maintenance, and diagnose and resolve any operational issues promptly.

2. Compliance with Quality Standards

Seamer Operators adhere to stringent quality standards to ensure the integrity and safety of the packaged products. They conduct regular inspections of the seams and containers, monitor the seaming process, and make adjustments as needed.

3. Production Monitoring and Control

Seamer Operators closely monitor production rates, output quality, and machine performance. They identify and address any deviations from standard operating procedures, optimizing productivity while maintaining quality.

4. Troubleshooting and Problem-Solving

Seamer Operators anticipate and respond to potential issues in the seaming process. They troubleshoot problems, make necessary adjustments, and collaborate with maintenance teams to ensure minimal downtime.

Interview Tips

To ace an interview for a Seamer Operator position, it’s essential to showcase your technical skills, problem-solving abilities, and attention to detail. Here are some helpful tips to prepare for the interview:

1. Research the Company and Position

Familiarize yourself with the company’s background, products, and specific requirements for the Seamer Operator role. This demonstrates your interest and preparedness.

2. Highlight Relevant Experience and Skills

Emphasize your previous experience in operating and maintaining seaming equipment. Highlight your ability to troubleshoot problems, maintain quality standards, and optimize production.

3. Demonstrate Technical Proficiency

Be prepared to discuss technical aspects of seaming technology, such as machine calibration, seam types, and quality control procedures. Use specific examples to demonstrate your expertise.

4. Share Problem-Solving Approaches

Describe how you approach troubleshooting issues in the seaming process. Share examples of challenges you’ve faced and how you resolved them effectively. This showcases your analytical abilities and problem-solving mindset.

5. Emphasize Quality and Safety

Stress your commitment to maintaining high standards of product quality and safety. Explain how you ensure proper seam inspections and adhere to all safety regulations.

6. Prepare for Common Interview Questions

Practice answering common interview questions such as “Tell me about your experience with seaming equipment” or “How do you handle production pressure while maintaining quality?” Prepare concise and specific responses.

7. Dress Professionally and Arrive Punctually

Make a positive first impression by dressing professionally and arriving for the interview on time. This demonstrates your respect for the interviewer and your commitment to the role.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Seamer Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.