Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Tape Controlled Machine Stitcher position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

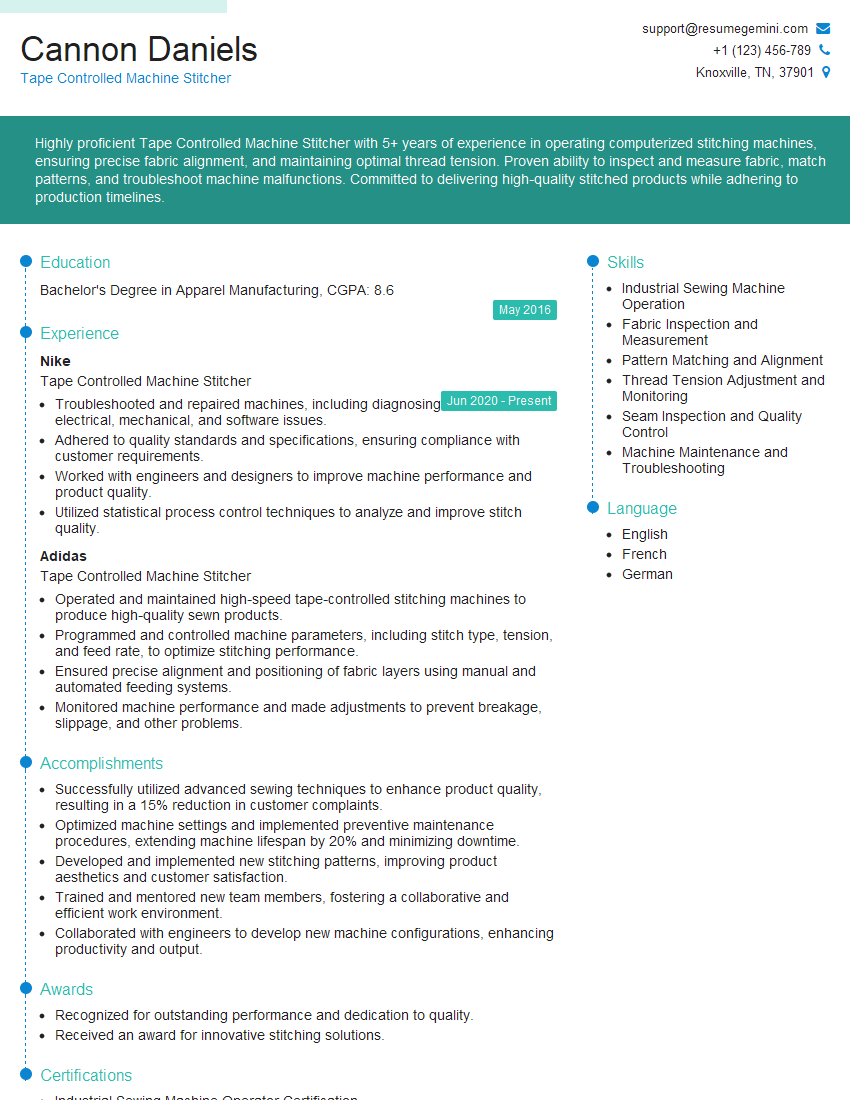

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Tape Controlled Machine Stitcher

1. What are the key responsibilities of a Tape Controlled Machine Stitcher?

- Set up and operate tape controlled stitching machines to stitch garments or other textile products.

- Inspect stitched products for defects and make any necessary adjustments.

- Maintain and clean stitching machines and work area.

- Follow safety procedures and wear appropriate safety gear.

- May be responsible for training new employees.

2. What are the different types of tape controlled stitching machines?

Numerical Control (NC) Machines

- Computer Numerical Control (CNC) Machines

- Direct Numerical Control (DNC) Machines

Programmable Logic Control (PLC) Machines

- Sequential Function Chart (SFC) Machines

- Ladder Logic (LL) Machines

3. What are the advantages of using tape controlled stitching machines?

- Faster and more accurate than manual stitching.

- Can produce complex stitches and patterns.

- Can be used to stitch a variety of materials.

- Can be integrated with other automated systems.

4. What are the different types of stitches that can be produced by a tape controlled stitching machine?

- Straight stitch

- Zigzag stitch

- Overlock stitch

- Coverstitch

- Bar tack stitch

5. What is the difference between a single-needle and a double-needle tape controlled stitching machine?

- Single-needle machines use one needle to create a single line of stitching.

- Double-needle machines use two needles to create two parallel lines of stitching.

- Double-needle machines are often used for heavier fabrics or for creating decorative stitches.

6. What types of materials can be stitched using a tape controlled stitching machine?

- Fabric

- Leather

- Vinyl

- Canvas

- Denim

7. What are the safety precautions that should be taken when operating a tape controlled stitching machine?

- Wear appropriate safety gear, including safety glasses, earplugs, and gloves.

- Keep hands away from moving parts.

- Never reach over or under a moving machine.

- Be aware of the location of the emergency stop button.

- Keep the work area clean and free of debris.

8. How do you troubleshoot a tape controlled stitching machine?

- Check the power supply.

- Check the thread tension.

- Check the needle.

- Check the bobbin.

- Check the stitch settings.

- Check the machine for any loose or damaged parts.

9. What are the different types of maintenance that should be performed on a tape controlled stitching machine?

Daily Maintenance

- Clean the machine head and bed.

- Oil the moving parts.

- Check the thread tension.

- Check the needle.

- Check the bobbin.

Weekly Maintenance

- Clean the machine thoroughly.

- Inspect the machine for any loose or damaged parts.

- Lubricate the machine.

- Adjust the stitch settings.

Monthly Maintenance

- Have the machine serviced by a qualified technician.

10. What are the key skills and qualifications that are required for a Tape Controlled Machine Stitcher?

- Experience operating tape controlled stitching machines.

- Knowledge of different types of stitches and fabrics.

- Ability to read and interpret sewing patterns.

- Ability to troubleshoot and repair minor machine problems.

- Strong attention to detail.

- Good hand-eye coordination.

- Ability to work independently and as part of a team.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Tape Controlled Machine Stitcher.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Tape Controlled Machine Stitcher‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Tape Controlled Machine Stitchers are responsible for operating and maintaining automated stitching machines that sew together various materials, including fabrics, leather, and plastics. They play a crucial role in the manufacturing process, ensuring the precise and efficient assembly of products. Key responsibilities of a Tape Controlled Machine Stitcher include:

1. Machine Operation

Operate tape controlled stitching machines to sew together materials accurately and efficiently.

- Load and position materials on the machine

- Program and adjust the machine settings according to the specific stitching requirements

- Monitor the stitching process and make necessary adjustments to ensure optimal stitch quality

2. Machine Maintenance

Perform regular maintenance and troubleshooting on stitching machines to ensure optimal performance.

- Clean and lubricate machine components

- Identify and repair minor malfunctions

- Report any major issues to the supervisor or maintenance personnel

3. Quality Control

Inspect stitched products to ensure they meet the required quality standards.

- Check for stitch quality, uniformity, and strength

- Identify and correct any defects or imperfections

- Maintain records of quality control inspections

4. Training and Safety

Receive training on new equipment and techniques to improve skills and knowledge.

- Attend scheduled training sessions

- Stay updated on industry best practices

- Follow all safety protocols and regulations related to machine operation and maintenance

Interview Tips

To ace an interview for a Tape Controlled Machine Stitcher position, it is essential to prepare thoroughly. Here are some tips and interview preparation hacks:

1. Research the Role and Company

Before the interview, take the time to research the specific job description and company you are applying to. This will help you understand the company’s culture, business objectives, and the role’s specific requirements.

- Review the job description carefully and identify the key responsibilities.

- Visit the company’s website to learn about their products, services, and company culture.

2. Highlight Your Relevant Experience and Skills

In your resume and interview, emphasize your relevant experience and skills that match the job requirements. This may include your experience operating and maintaining stitching machines, performing quality control inspections, or working in a manufacturing environment.

- Quantify your accomplishments whenever possible, using specific metrics and examples.

- Tailor your responses to the specific questions asked by the interviewer, highlighting how your skills and experience make you a suitable candidate for the role.

3. Practice Common Interview Questions

Prepare for common interview questions by practicing your answers beforehand. This will help you feel more confident and articulate during the interview. Some common interview questions you may encounter include:

- “Tell me about your experience operating and maintaining stitching machines.”

- “How do you ensure the quality of your work?”

- “What is your understanding of the role of a Tape Controlled Machine Stitcher in a manufacturing environment?”

4. Prepare for Technical Questions

Depending on the specific role and company, you may encounter technical questions during the interview. These questions may assess your knowledge of stitching machine operation, maintenance, and quality control techniques. To prepare for these questions:

- Review the basics of stitching machine operation and maintenance.

- Familiarize yourself with industry best practices for quality control in manufacturing.

5. Ask Thoughtful Questions

At the end of the interview, take the opportunity to ask the interviewer questions about the role, company, and industry. This shows that you are engaged and interested in the position. Some insightful questions you could ask include:

- “What are the company’s growth plans for the future?”

- “Can you provide more details about the training and development opportunities available to employees?”

- “What are the company’s expectations for productivity and quality in this role?”

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Tape Controlled Machine Stitcher, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Tape Controlled Machine Stitcher positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.