Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Sueding Machine Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

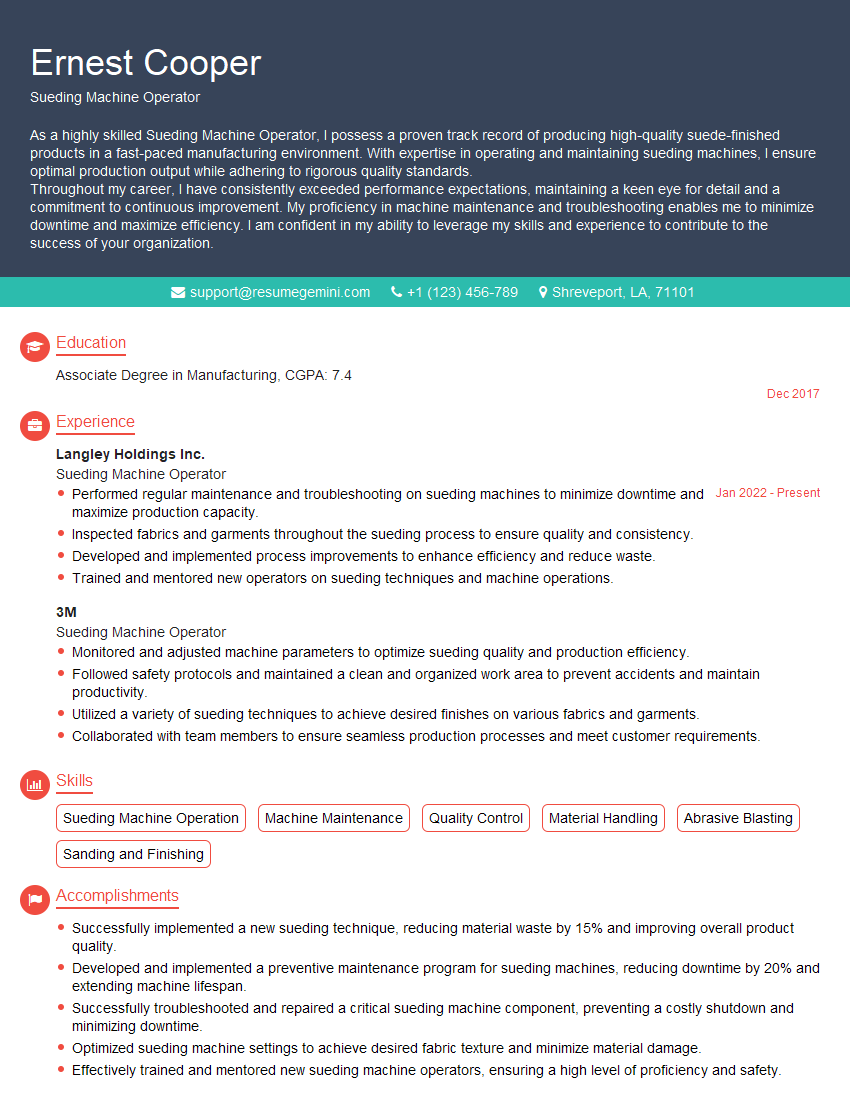

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Sueding Machine Operator

1. Describe the key steps involved in operating a sueding machine?

- Adjusting the machine settings according to the desired finish.

- Loading the fabric onto the machine’s conveyor belt.

- Monitoring the machine’s operation and making necessary adjustments as needed.

- Unloading the finished fabric from the machine.

- Cleaning and maintaining the machine.

2. What are the different types of fabrics that can be suede-finished?

Natural fabrics

- Cotton

- Linen

- Silk

- Wool

Synthetic fabrics

- Nylon

- Polyester

- Acrylic

- Spandex

3. What are the safety precautions that must be taken when operating a sueding machine?

- Wearing appropriate personal protective equipment, such as gloves, safety glasses, and a dust mask.

- Keeping the work area clean and free of debris.

- Never reaching into the machine while it is running.

- Shutting off the machine and unplugging it before performing any maintenance or repairs.

4. How do you troubleshoot common problems that may arise when operating a sueding machine?

- The fabric is not being suede-finished properly.

- The machine is making a strange noise.

- The machine is not turning on.

5. What are the different types of sueding brushes?

- Nylon brushes

- Wire brushes

- Natural fiber brushes

6. What are the factors that affect the quality of a suede-finished fabric?

- The type of fabric.

- The settings of the sueding machine.

- The skill of the machine operator.

7. What is the difference between sueding and napping?

- Sueding is a process that creates a soft, velvety finish on fabric.

- Napping is a process that creates a raised surface on fabric.

8. What are the different applications for suede-finished fabrics?

- Clothing

- Upholstery

- Toys

- Accessories

9. What are the maintenance tasks that need to be performed on a sueding machine?

- Cleaning the machine regularly.

- Lubricating the machine’s moving parts.

- Inspecting the machine’s brushes for wear and tear.

- Replacing the machine’s brushes as needed.

10. What are the qualities of a successful sueding machine operator?

- Attention to detail

- Mechanical aptitude

- Patience

- Ability to work independently

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Sueding Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Sueding Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Sueding Machine Operators are responsible for operating and maintaining sueding machines, which are used to give fabrics a suede-like texture or finish. Their duties encompass ensuring machine operations run smoothly, making adjustments to achieve desired results, and performing routine maintenance to keep the equipment in optimal condition.

1. Machine Operation

Operators are tasked with setting up and operating sueding machines efficiently. They ensure that machine settings are calibrated correctly to produce the desired texture and finish on the fabric. Close attention is paid to material tension, roller speed, and abrasive grit to achieve the required specifications.

- Setting and calibrating machine parameters for different fabric types and desired finishes

- Monitoring machine performance and making adjustments as needed to maintain consistent output

- Troubleshooting and resolving any machine malfunctions or breakdowns

2. Quality Control

Maintaining high quality standards is crucial for Sueding Machine Operators. They are responsible for inspecting fabrics post-processing to ensure they meet specifications and customer expectations. They identify and rectify any defects or inconsistencies, ensuring the final product meets the required standards.

- Visually inspecting fabrics for quality, texture, and color uniformity

- Identifying and addressing any inconsistencies or defects in the sueding process

- Maintaining detailed records of production and quality control measures

3. Maintenance and Cleaning

Regular maintenance is essential to keep sueding machines operating efficiently. Operators are responsible for performing routine cleaning, lubrication, and minor repairs to ensure optimal performance. They also monitor machine components for wear and tear, reporting any issues to supervisors for timely maintenance.

- Cleaning and lubricating machine parts to prevent breakdowns

- Inspecting and replacing worn or damaged components

- Following manufacturer’s guidelines for maintenance and repair procedures

4. Health and Safety

Adhering to health and safety protocols is paramount. Operators are responsible for wearing appropriate personal protective equipment (PPE) while operating machines and handling materials. They follow established safety procedures to minimize risks and maintain a safe work environment.

- Wearing appropriate PPE, including gloves, masks, and safety glasses

- Following established safety protocols and procedures

- Reporting any hazardous conditions or unsafe practices

Interview Tips

Preparing effectively for a Sueding Machine Operator interview can significantly improve your chances of success. Here are some crucial tips and hacks to guide you through the process:

1. Research the Company

Before the interview, take the time to research the company, their products, and their values. Understanding the company’s culture and business objectives will help you tailor your answers and demonstrate your genuine interest in the role.

- Visit the company website and social media pages

- Read industry news and articles related to the company

- Connect with current or former employees on LinkedIn

2. Practice Common Interview Questions

Many interview questions are common across industries. Prepare for these questions by practicing your responses out loud. This will boost your confidence and ensure you present a clear and concise message.

- Tell me about yourself.

- Why are you interested in this role?

- What are your strengths and weaknesses?

3. Highlight Relevant Experience and Skills

Emphasize your experience and skills that are directly relevant to the Sueding Machine Operator role. Quantify your accomplishments whenever possible to showcase the impact of your contributions.

- Describe your experience operating and maintaining sueding machines

- Share examples of how you maintained quality standards and resolved machine issues

- Mention any certifications or training related to sueding or textile processing

4. Be Enthusiastic and Professional

Throughout the interview, maintain a positive and enthusiastic demeanor. Show the interviewer that you are genuinely interested in the role and the company. Dress professionally and arrive on time for your interview to make a good first impression.

- Smile, make eye contact, and speak clearly

- Be respectful and listen attentively to the interviewer’s questions

- Ask thoughtful questions to demonstrate your engagement

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Sueding Machine Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.