Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Turner In position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

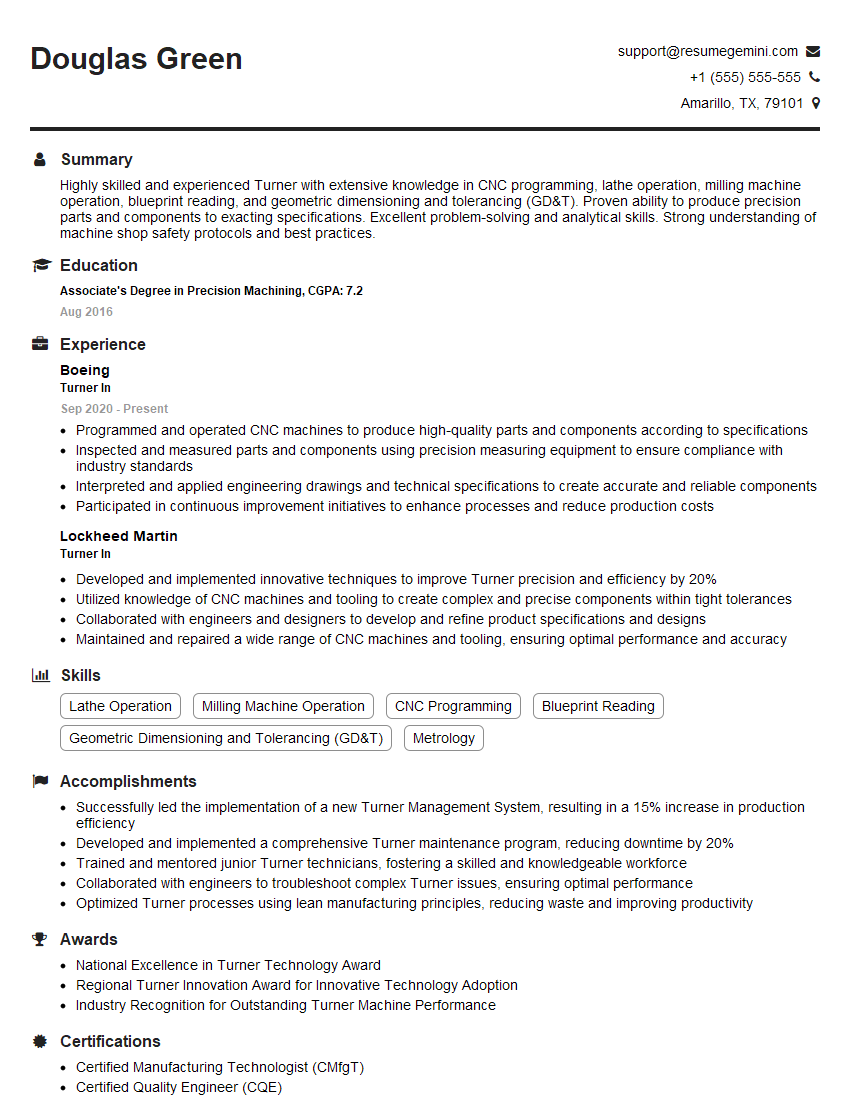

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Turner In

1. What are the key principles of turning?

The key principles of turning include:

- Using a lathe to rotate the workpiece while a cutting tool is fed into it.

- Controlling the speed of rotation, feed rate, and depth of cut to achieve the desired shape and finish.

- Selecting the appropriate cutting tool based on the material being turned and the desired finish.

- Monitoring the process to ensure that the workpiece is being produced to the required specifications.

2. What are the different types of turning operations?

External turning

- Reducing the diameter of a workpiece

- Creating a specific shape on the outer surface

Internal turning

- Enlarging the diameter of a hole

- Creating a specific shape on the inner surface

Threading

- Creating a helical groove on the workpiece

- Used to create fasteners or for joining components

Facing

- Producing a flat surface on the end of the workpiece

- Used to create a reference surface or to prepare the workpiece for further operations

3. What are the advantages of using a CNC lathe for turning operations?

- Increased accuracy and precision

- Improved surface finish

- Reduced cycle times

- Reduced labor costs

- Increased productivity

4. What are the different types of cutting tools used in turning?

- Single-point cutting tools

- Multi-point cutting tools

- Boring tools

- Threading tools

- Knurling tools

5. How do you select the appropriate cutting tool for a turning operation?

- Consider the material being turned

- Consider the desired surface finish

- Consider the type of turning operation being performed

- Refer to cutting tool manufacturers’ recommendations

6. How do you calculate the cutting speed for a turning operation?

The cutting speed can be calculated using the following formula:

- Cutting speed (m/min) = (π × spindle speed (rpm) × cutting diameter (mm)) / 1000

7. How do you set up a CNC lathe for a turning operation?

- Mount the workpiece onto the lathe chuck

- Select the appropriate cutting tool

- Program the CNC lathe with the desired cutting parameters

- Start the cutting process

- Monitor the process to ensure that the workpiece is being produced to the required specifications

8. What are the common problems that can occur during turning operations?

- Chatter

- Tool wear

- Surface finish problems

- Dimensional accuracy problems

9. How do you troubleshoot common problems that occur during turning operations?

- Chatter: Reduce the cutting speed or feed rate, increase the tool overhang, or use a different cutting tool.

- Tool wear: Replace the cutting tool.

- Surface finish problems: Use a different cutting tool or adjust the cutting parameters.

- Dimensional accuracy problems: Check the machine setup and cutting parameters, and ensure that the workpiece is properly secured.

10. What are the safety precautions that must be taken when performing turning operations?

- Wear appropriate safety gear, including eye protection, ear protection, and gloves.

- Keep the work area clean and free of debris.

- Ensure that the machine is properly guarded.

- Never reach into the machine while it is running.

- Be aware of the hazards associated with rotating machinery.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Turner In.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Turner In‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Turner Ins are responsible for turning raw materials into finished products using machine tools. They work in various industries, including automotive, aerospace, and manufacturing.

1. Planning and Preparation

Turner Ins plan and prepare for turning operations by studying blueprints, determining tool requirements, and setting up machines.

- Interpret blueprints and other technical drawings to determine the size, shape, and tolerance of the workpiece.

- Select the appropriate cutting tools, tool holders, and accessories for the job.

- Set up and adjust the machine to the correct speed, feed, and depth of cut.

2. Machining Operations

Turner Ins perform machining operations using lathes, mills, and other machine tools. They use cutting tools to remove material from the workpiece and create the desired shape and size.

- Operate lathes, mills, and other machine tools to cut and shape metal.

- Use cutting tools to remove material from the workpiece and create the desired shape and size.

- Monitor the machining process and make adjustments as needed to ensure the correct dimensions and finish.

3. Finishing and Inspection

Turner Ins finish and inspect the finished product to ensure that it meets the required specifications. They use various tools and equipment to measure, gauge, and check the product.

- Measure and inspect the finished product to ensure that it meets the required specifications.

- Use various tools and equipment to measure, gauge, and check the product.

- Make adjustments to the machining process as needed to improve the quality of the finished product.

4. Machine Maintenance

Turner Ins maintain their machines and tools to ensure that they are in good working order. They perform regular maintenance tasks, such as cleaning, lubrication, and calibration.

- Perform regular maintenance tasks, such as cleaning, lubrication, and calibration.

- Identify and troubleshoot machine problems.

- Make minor repairs to machines and tools.

Interview Tips

Preparing for a Turner In interview can help you increase your chances of success. Here are some tips to help you ace the interview:

1. Research the Company and Position

Take the time to learn about the company and the specific position you’re applying for. This will help you answer questions intelligently and demonstrate your interest in the role.

- Visit the company’s website to learn about their history, mission, and products or services.

- Read online reviews and articles about the company to get an insider’s perspective.

- Review the job description carefully and identify the key skills and qualifications required for the position.

2. Practice Your Answers

Once you’ve done your research, take some time to practice your answers to common interview questions. This will help you feel more confident and articulate during the interview.

- Prepare answers to questions about your experience, skills, and qualifications.

- Practice answering questions about your strengths and weaknesses.

- Prepare questions to ask the interviewer about the company and the position.

3. Dress Professionally

First impressions matter, so make sure you dress professionally for your interview. This means wearing clean, pressed clothes that are appropriate for a business setting.

- Wear a suit or dress pants and a button-down shirt.

- Make sure your clothes are clean and pressed.

- Avoid wearing casual clothes, such as jeans or t-shirts.

4. Be Punctual

Punctuality is important for any interview, but it’s especially important for a Turner In interview. This job requires you to be able to work independently and meet deadlines, so being on time for your interview is a good way to show that you’re reliable and responsible.

- Plan your route to the interview in advance so that you know how long it will take you to get there.

- Leave yourself plenty of time to get to the interview, even if you think you know the way.

- If you’re running late, call the interviewer and let them know.

5. Be Confident

Finally, remember to be confident during your interview. This doesn’t mean being arrogant, but it does mean believing in yourself and your abilities. The more confident you are, the more likely you are to make a good impression on the interviewer.

- Make eye contact with the interviewer and speak clearly and concisely.

- Be enthusiastic about the position and the company.

- Don’t be afraid to ask questions.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Turner In interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.