Are you gearing up for an interview for a Turn Laster position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Turn Laster and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

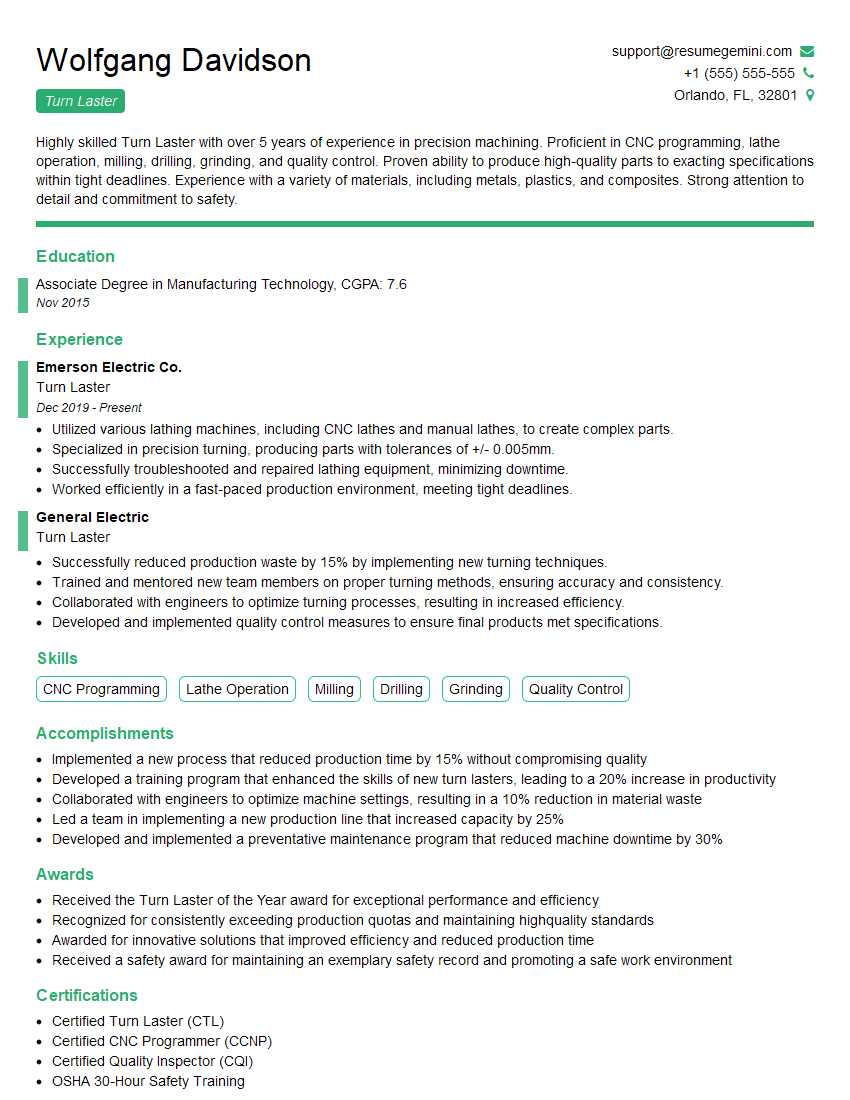

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Turn Laster

1. What are the different types of turning operations?

There are various types of turning operations, including:

- Straight turning: Creates cylindrical shapes by removing material from the workpiece’s outer surface.

- Taper turning: Produces conical shapes by gradually reducing the workpiece’s diameter.

- Form turning: Uses a specially shaped tool to create complex profiles on the workpiece.

- Thread cutting: Cuts threads into the workpiece using a threading tool.

- Facing: Creates flat surfaces perpendicular to the workpiece’s axis.

- Grooving: Creates grooves or channels in the workpiece.

2. How do you select the appropriate cutting speed and feed rate for turning?

Factors to consider:

- Workpiece material hardness and toughness

- Tool material and geometry

- Machine capabilities (spindle speed, feed rate range)

- Desired surface finish

General guidelines:

- Harder materials require lower cutting speeds and higher feed rates.

- Sharper tools can handle higher cutting speeds.

- Higher feed rates result in lower surface finish.

3. Explain the difference between a carbide and a high-speed steel cutting tool.

-

Carbide tool:

- Made of tungsten carbide or similar hard materials

- Excellent wear resistance, allowing for higher cutting speeds

- Suitable for machining hard and abrasive materials

- More expensive than high-speed steel tools High-speed steel tool:

- Made of steel alloyed with vanadium, cobalt, or other elements

- Less wear resistance and lower cutting speeds compared to carbide

- Suitable for machining soft and medium-hard materials

- More common and less expensive than carbide tools

4. What are the common causes of chatter in turning operations?

- Inadequate tool rigidity

- Excessive overhang of the cutting tool

- Loose workpiece or tool holder

- Insufficient cutting speed or feed rate

- Resonance in the workpiece or machine

- Dull or worn cutting tool

5. How do you measure the accuracy of a turned part?

- Use precision measuring instruments such as micrometers, calipers, or coordinate measuring machines (CMMs)

- Measure critical dimensions and compare them to specifications

- Check for roundness, straightness, and tolerance within acceptable limits

- Use statistical process control techniques to ensure consistent accuracy

6. What are the safety precautions to observe when operating a lathe?

- Wear appropriate protective gear (safety glasses, gloves, hearing protection, etc.)

- Inspect the lathe and ensure it is in good working condition

- Secure the workpiece properly and use appropriate tooling

- Keep hands away from rotating parts

- Be aware of the machine’s motion and anticipate potential hazards

- Never leave the lathe unattended while it is operating

7. How do you troubleshoot a problem with the workpiece not being round after turning?

- Inspect the cutting tool for wear or damage

- Check the toolholder for proper alignment and tightness

- Ensure that the workpiece is securely clamped

- Adjust the cutting speed or feed rate

- Check for any vibrations in the machine or workpiece

- Consider using a live center or steady rest for additional support

8. What is the difference between a CNC lathe and a manual lathe?

-

CNC lathe:

- Computer-controlled, allows for automated operation

- Uses G/M codes to program specific machining operations

- Higher precision and repeatability

- Capable of complex machining operations Manual lathe:

- Requires manual operation of the machine

- Less precise and consistent than CNC lathes

- Suitable for small-scale production and one-off jobs

- Requires skilled operators

9. What are the different types of cutting fluids used in turning operations?

- Soluble oils: Emulsions of oil in water

- Straight oils: Pure oils without any water

- Synthetic fluids: Chemically engineered fluids

- Semi-synthetic fluids: Mixtures of soluble oils and synthetic fluids

Functions of cutting fluids:

- Cooling the cutting tool and workpiece

- Lubricating the cutting zone

- Removing chips and contaminants

- Protecting the workpiece from corrosion

10. How do you calculate the cutting time for a turning operation?

- Calculate the cutting length: Length of the workpiece that needs to be turned

- Determine the feed rate: Velocity at which the cutting tool moves

- Formula: Cutting time = Cutting length / Feed rate

Example:

- Cutting length: 300 mm

- Feed rate: 0.2 mm/rev

- Cutting time = 300 mm / 0.2 mm/rev = 1500 revolutions

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Turn Laster.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Turn Laster‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

As a Turn Laster, you will play a vital role in precision manufacturing, ensuring the production of high-quality products. Your primary responsibilities include:

1. Turn Workpieces

Operate a lathe machine to turn cylindrical or flat workpieces. Utilize various cutting tools to create desired shapes and dimensions.

- Plan and set up machining operations, including tool selection and cutting parameters.

- Monitor workpiece rotation and cutting progress to ensure accuracy.

2. Measure and Inspect Turnings

Inspect finished turnings using precision measuring instruments. Verify dimensions, surface finish, and other quality specifications.

- Identify and correct any discrepancies or defects.

- Maintain detailed records of inspection results.

3. Set Up and Maintain Equipment

Configure lathe machines according to job specifications. Install and replace cutting tools, adjust speeds and feeds, and ensure proper lubrication.

- Perform basic maintenance and troubleshooting to optimize equipment performance.

- Follow safety protocols and wear appropriate protective gear.

4. Coordinate with Team

Collaborate with team members, engineers, and quality control personnel. Share technical information, discuss project updates, and contribute to continuous improvement.

- Maintain a positive and proactive work environment.

- Contribute to training and development initiatives.

Interview Tips

To ace your interview for a Turn Laster position, consider the following preparation tips:

1. Research the Company and Role

Gather information about the company’s industry, products, and mission. Review the job description thoroughly to understand the specific requirements.

- Visit the company website and social media pages.

- Network with industry professionals on LinkedIn.

2. Highlight Relevant Skills and Experience

Emphasize your proficiency in lathe machine operation, measurement techniques, and quality control procedures. Showcase your ability to read blueprints, interpret specifications, and work independently.

- Provide concrete examples of your success in previous roles.

- Quantify your accomplishments whenever possible.

3. Prepare for Technical Questions

Expect questions about lathe setup, cutting tool selection, and inspection techniques. Study common machining principles and industry standards.

- Practice solving machining problems.

- Review safety protocols and best practices.

4. Demonstrate Teamwork and Communication

Highlight your ability to work effectively in a team environment. Describe instances where you contributed to problem-solving and shared knowledge with colleagues.

- Emphasize your communication skills and willingness to collaborate.

- Provide examples of successful team projects.

5. Be Professional and Enthusiastic

Dress professionally, arrive on time, and maintain a positive attitude throughout the interview. Demonstrate your enthusiasm for the role and the opportunity to contribute to the company’s success.

- Be respectful and ask thoughtful questions.

- Follow up with a thank-you note expressing your interest.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Turn Laster interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.