Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Vulcanizing Press Operator interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Vulcanizing Press Operator so you can tailor your answers to impress potential employers.

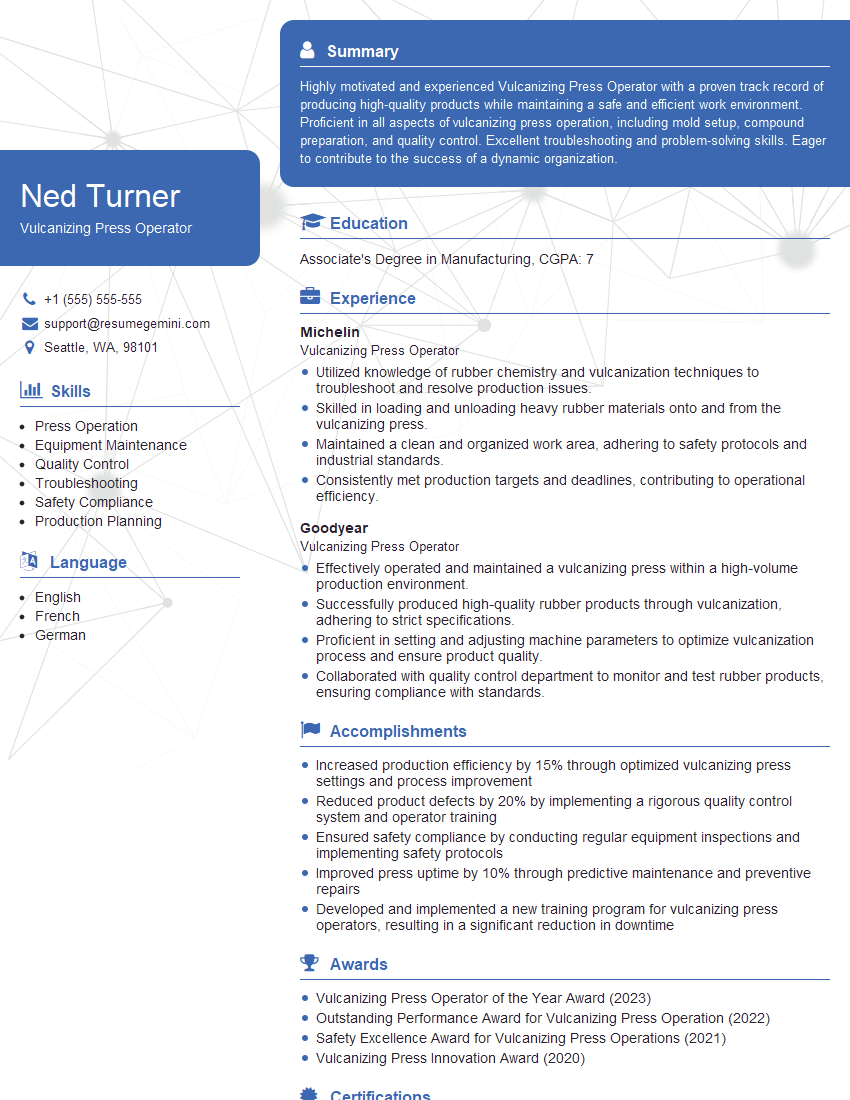

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Vulcanizing Press Operator

1. Explain the key responsibilities of a Vulcanizing Press Operator?

- Operate vulcanizing presses to cure and bond rubber and rubber-like materials.

- Load presses with materials, set controls, and monitor the curing process.

- Unload presses and inspect finished products for defects.

- Maintain and clean presses and equipment.

- Follow safety procedures and wear appropriate safety gear.

2. Describe the process of vulcanization and the role of the Vulcanizing Press Operator?

Vulcanization Process

- Vulcanization is a chemical process that transforms natural rubber into a more durable and elastic material.

- It involves heating rubber with sulfur and other chemicals under pressure.

Role of Vulcanizing Press Operator

- The operator sets the press to the correct temperature and pressure.

- Loads the press with rubber and other materials.

- Monitors the curing process and adjusts settings as needed.

- Once the curing process is complete, the operator unloads the press and inspects the finished product.

3. What are the different types of vulcanizing presses and their applications?

- Platen presses: Used for flat or slightly curved products.

- Bladder presses: Used for products with complex shapes.

- Continuous vulcanizers: Used for long, continuous products such as conveyor belts.

4. What are the safety precautions that must be taken when operating a vulcanizing press?

- Wear appropriate safety gear, including gloves, safety glasses, and earplugs.

- Never touch hot surfaces.

- Keep work area clean and free of tripping hazards.

- Follow all safety procedures and guidelines.

5. How do you troubleshoot common problems that may occur when operating a vulcanizing press?

- Press not heating up: Check power supply, heating elements, and temperature controller.

- Press not closing properly: Check hydraulic system, pressure gauges, and valves.

- Product not curing properly: Check temperature and pressure settings, cure time, and material quality.

6. What are the quality control checks that need to be performed during the vulcanization process?

- Inspect raw materials for defects.

- Monitor temperature and pressure throughout the curing process.

- Inspect finished products for dimensions, shape, and surface finish.

- Perform destructive and non-destructive tests to ensure product quality.

7. Describe your experience in maintaining and repairing vulcanizing presses?

- Regularly lubricate moving parts.

- Inspect and replace worn or damaged components.

- Troubleshoot and repair electrical and hydraulic systems.

- Follow manufacturer’s maintenance and repair guidelines.

8. How do you stay up-to-date with the latest advancements in vulcanization technology?

- Attend industry conferences and seminars.

- Read trade publications and technical journals.

- Consult with industry experts and suppliers.

9. What are the challenges you have faced as a Vulcanizing Press Operator and how did you overcome them?

- Equipment malfunction: Troubleshot the issue and quickly repaired the press to minimize downtime.

- Product quality issues: Worked with engineers to adjust process parameters and improve product quality.

- Meeting production targets: Optimized processes and implemented lean manufacturing techniques to increase efficiency.

10. Why are you interested in this Vulcanizing Press Operator position?

- Passion for the rubber industry and vulcanization process.

- Experience and expertise in operating and maintaining vulcanizing presses.

- Commitment to safety and quality in manufacturing.

- Desire to contribute to the team and help the company succeed.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Vulcanizing Press Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Vulcanizing Press Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Vulcanizing Press Operators are responsible for overseeing the operation of vulcanizing presses, which are used to fuse rubber materials together. They are expected to perform various tasks related to the operation and maintenance of these machines.

1. Press Operation

Vulcanizing Press Operators are responsible for operating vulcanizing presses to fuse rubber materials together.

- Set up and operate vulcanizing presses according to established procedures.

- Control temperature, pressure, and time cycles to ensure proper vulcanization.

- Monitor gauges and instruments to maintain optimal operating conditions.

2. Material Handling

Vulcanizing Press Operators are responsible for handling and loading materials into the vulcanizing presses.

- Prepare and load rubber materials into the presses.

- Unload cured rubber products and inspect them for quality.

- Maintain a clean and organized work area.

3. Maintenance and Inspection

Vulcanizing Press Operators are responsible for performing basic maintenance and inspections on the vulcanizing presses.

- Perform routine maintenance and lubrication tasks.

- Inspect presses for wear and tear, and report any issues to supervisors.

- Clean and repair equipment when necessary.

4. Quality Control

Vulcanizing Press Operators are responsible for monitoring the quality of the vulcanized products.

- Inspect finished products for defects and ensure they meet specifications.

- Work closely with quality control personnel to ensure product quality.

- Maintain accurate records of production and quality data.

Interview Tips

Preparing for an interview can be nerve-wracking, but with the right preparation and strategies, you can increase your chances of success.

1. Research the Company and Position

Take the time to research the company and the specific Vulcanizing Press Operator position you are applying for.

- Visit the company’s website and social media pages to learn about their mission, values, and recent news.

- Read industry publications and articles to stay up-to-date on the latest trends and technologies.

- Study the job description carefully to understand the key responsibilities and qualifications.

2. Practice Your Answers to Common Interview Questions

There are some common interview questions that you can expect to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” Practice answering these questions in a clear and concise manner.

- Use the STAR method (Situation, Task, Action, Result) to structure your answers.

- Focus on highlighting your relevant skills and experience.

- Quantify your accomplishments whenever possible.

3. Prepare Questions to Ask the Interviewer

Asking well-thought-out questions at the end of the interview shows that you are engaged and interested in the position.

- Ask about the company’s culture and values.

- Inquire about the specific projects or initiatives that the team is working on.

- Ask about opportunities for professional development and growth.

4. Dress Professionally and Arrive on Time

First impressions matter, so dress professionally and arrive on time for your interview. This shows that you are respectful of the interviewer’s time and that you take the interview process seriously.

- Choose clothing that is clean, pressed, and appropriate for a business setting.

- Plan your route ahead of time and allow extra time for traffic or unexpected delays.

- Be punctual and greet the interviewer with a firm handshake and a smile.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Vulcanizing Press Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.