Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Ammonia Box Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

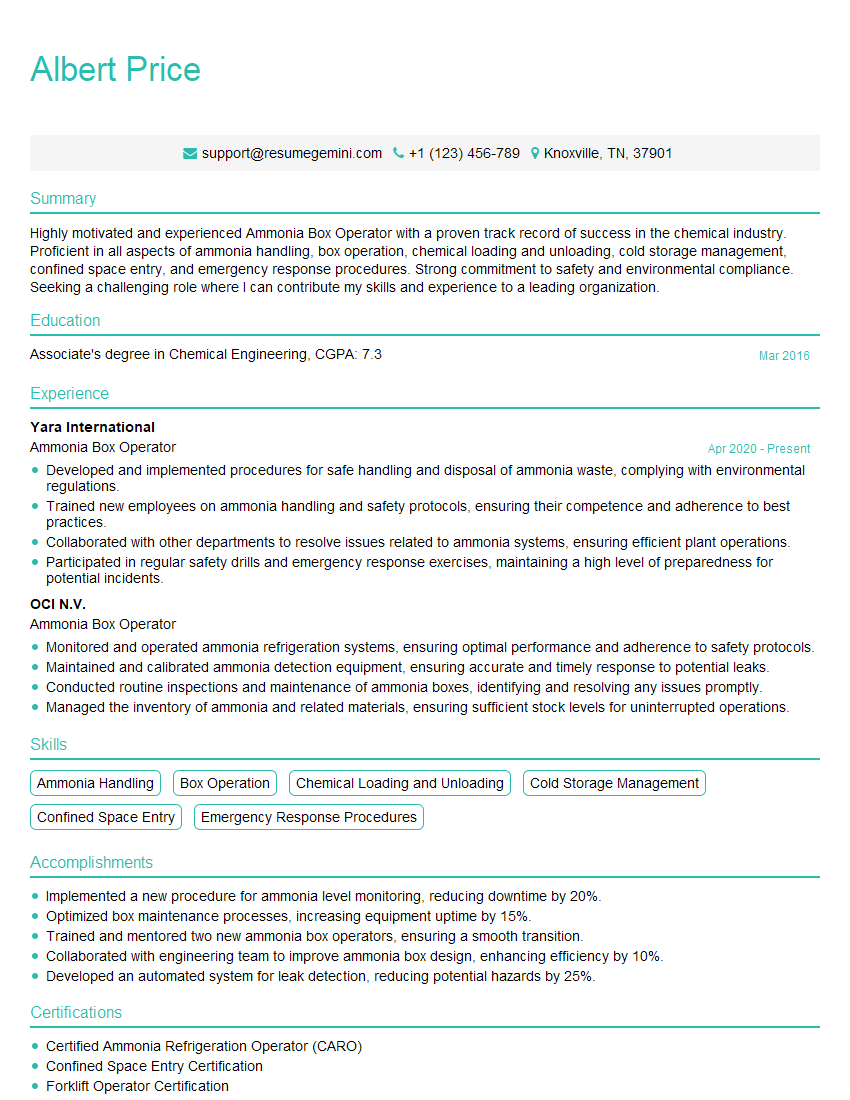

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Ammonia Box Operator

1. Describe the key responsibilities of an Ammonia Box Operator?

An Ammonia Box Operator plays a pivotal role in ensuring the safe and efficient operation of ammonia boxes. Their responsibilities encompass:

- Monitoring and maintaining the ammonia box system, including the chiller, condenser, and evaporator

- Conducting periodic inspections to detect potential leaks or malfunctions

- Operating and adjusting the ammonia box to optimize cooling performance

- Ensuring compliance with safety protocols and environmental regulations

- Maintaining a clean and organized work area

2. What are the safety precautions that must be taken when working with ammonia?

Handling ammonia requires adherence to strict safety measures. As an Ammonia Box Operator, I am acutely aware of these precautions, which include:

Personal Protective Equipment

- Wearing appropriate personal protective equipment (PPE) such as gloves, goggles, and respirators

- Inspecting PPE regularly for any damage or defects

Emergency Procedures

- Being familiar with emergency procedures in case of an ammonia leak

- Knowing the location and proper use of ammonia detectors and alarms

Training and Awareness

- Undergoing regular training on safe ammonia handling practices

- Staying informed about industry regulations and best practices

3. How do you prioritize tasks and manage multiple responsibilities as an Ammonia Box Operator?

Balancing multiple responsibilities effectively is crucial for an Ammonia Box Operator. I prioritize tasks based on their urgency and importance, ensuring that critical tasks are addressed promptly.

- Creating and following a daily schedule to allocate time for different responsibilities

- Delegating tasks to colleagues when appropriate to optimize efficiency

- Communicating regularly with supervisors to provide updates and seek guidance

- Continuously monitoring the ammonia box system to identify any potential issues early on

4. Describe your experience in troubleshooting and resolving ammonia box malfunctions?

Troubleshooting and resolving ammonia box malfunctions require a combination of technical expertise and practical experience. In my previous role, I successfully addressed various issues, including:

- Diagnosing and repairing leaks in the ammonia piping system

- Adjusting the chiller settings to optimize cooling efficiency

- Replacing faulty sensors and components within the ammonia box

- Collaborating with maintenance technicians to resolve complex malfunctions

5. How do you maintain accurate records and ensure compliance with environmental regulations as an Ammonia Box Operator?

Maintaining accurate records and complying with environmental regulations are essential aspects of my role as an Ammonia Box Operator. I meticulously document all activities, including:

- Regular inspections and maintenance performed on the ammonia box system

- Any malfunctions or repairs that occur

- Training and safety briefings attended

6. What is your understanding of the refrigeration cycle and how does it apply to the operation of an ammonia box?

The refrigeration cycle is a fundamental concept in the operation of an ammonia box. I have a clear understanding of its four main components:

Components of Refrigeration Cycle

- Compressor: Compresses the refrigerant gas, increasing its pressure and temperature

- Condenser: Cools and condenses the compressed gas into a liquid

- Expansion Valve: Regulates the flow of liquid refrigerant into the evaporator

- Evaporator: Absorbs heat from the surrounding environment, causing the liquid refrigerant to evaporate

Ammonia Box Application

- In an ammonia box, ammonia acts as the refrigerant and undergoes the refrigeration cycle

- The evaporator is located inside the box, absorbing heat from the stored products

- The compressor, condenser, and expansion valve are typically located outside the box

7. How do you ensure that the ammonia box system operates at optimal efficiency?

Optimizing the efficiency of the ammonia box system requires regular maintenance and monitoring. I prioritize the following practices:

- Inspecting and cleaning the evaporator coils to prevent blockages

- Checking and adjusting the temperature and pressure settings

- Monitoring the refrigerant levels and replenishing as needed

- Conducting performance tests to assess the system’s efficiency

8. What steps do you take to minimize energy consumption while operating an ammonia box?

Energy conservation is a key aspect of my role as an Ammonia Box Operator. I implement the following measures to reduce energy consumption:

- Optimizing the temperature settings to avoid overcooling

- Regularly defrosting the evaporator coils to improve heat transfer

- Using energy-efficient equipment and appliances

9. How do you communicate effectively with colleagues, supervisors, and customers in your role as an Ammonia Box Operator?

Effective communication is essential in my role. I maintain open and regular dialogue with the following groups:

Colleagues

- Collaborate with fellow operators to share knowledge and support

- Inform colleagues about any potential hazards or issues

Supervisors

- Provide regular updates on the ammonia box system’s performance

- Seek guidance and support when needed

Customers

- Respond to inquiries about the ammonia box system and its operation

- Provide recommendations for maintaining optimal storage conditions

10. What is your approach to continuous improvement and professional development in your role as an Ammonia Box Operator?

Continuous improvement and professional development are essential for success in this field. I actively engage in the following practices:

- Attending training programs and workshops to enhance my technical knowledge

- Reading industry publications and participating in online forums to stay updated with best practices

- Seeking feedback from colleagues and supervisors to identify areas for improvement

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Ammonia Box Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Ammonia Box Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

An Ammonia Box Operator is responsible for managing and monitoring the operations of an ammonia box, which is essential for the production of ammonia in industrial settings. The primary focus of this role is to ensure the efficient and safe operation of the equipment while maintaining compliance with safety protocols and industry regulations.

1. Monitoring and Controlling Ammonia Box Operations

The main duty involves closely monitoring and controlling all aspects of the ammonia box’s operations. This includes tracking the flow rate of ammonia gas, temperature, and pressure within the system. The operator must promptly respond to any deviations from normal operating parameters and make necessary adjustments to maintain optimal conditions.

- Monitoring ammonia levels and ensuring they are within specified limits.

- Regulating the flow of ammonia gas into and out of the box.

- Maintaining optimal temperature and pressure levels.

2. Maintenance and Troubleshooting

The operator is also responsible for maintaining and troubleshooting the ammonia box. This includes performing regular inspections, identifying potential problems, and taking appropriate corrective actions. By conducting preventive maintenance tasks, the operator can minimize downtime and ensure the equipment operates reliably.

- Inspecting and cleaning the ammonia box regularly.

- Identifying and repairing any leaks or malfunctions.

- Calibrating and maintaining instruments and controls.

3. Safety and Compliance

Adhering to safety protocols and industry regulations is crucial for the Ammonia Box Operator. They must wear appropriate personal protective equipment (PPE) and follow established safety procedures to minimize risks associated with working with ammonia gas. Moreover, they must be aware of and comply with environmental regulations related to ammonia handling and disposal.

- Following established safety protocols and procedures.

- Using and maintaining PPE correctly.

- Complying with environmental regulations for ammonia handling.

4. Communication and Record-Keeping

Effective communication and record-keeping are essential aspects of the role. The operator must be able to communicate clearly with other team members, supervisors, and maintenance personnel to ensure smooth coordination and problem-solving. Maintaining accurate records of operations, maintenance activities, and any incidents is also essential for ensuring traceability and compliance.

- Communicating effectively with colleagues and supervisors.

- Keeping accurate records of operations and maintenance activities.

- Documenting any incidents or deviations from normal operating parameters.

Interview Tips

To ace the interview for the position of Ammonia Box Operator, candidates should prepare effectively and showcase their skills and experience. Here are some interview tips to help them succeed:

1. Research the Company and Position

Before the interview, candidates should thoroughly research the company and the specific role of Ammonia Box Operator. This will help them understand the organization’s culture, values, and the key responsibilities of the position. They should also familiarize themselves with industry trends and best practices related to ammonia handling and safety.

- Visit the company’s website and review their mission, vision, and recent news.

- Read industry publications and articles to stay updated on technical developments.

2. Highlight Relevant Skills and Experience

During the interview, candidates should emphasize their relevant skills and experience that align with the job requirements. They should provide specific examples of their abilities in monitoring and controlling ammonia box operations, performing maintenance and troubleshooting, and adhering to safety protocols. Quantifying their accomplishments using metrics or data will enhance their credibility.

- Describe instances where they effectively managed ammonia box operations and maintained optimal conditions.

- Showcase their expertise in troubleshooting and repairing equipment.

3. Demonstrate Safety Consciousness

Safety is paramount in this role, so candidates should demonstrate a strong understanding of safety protocols and their commitment to working safely. They should articulate their knowledge of ammonia handling hazards and explain their experience in following established safety procedures. Highlighting any safety certifications or training they have completed will further reinforce their safety consciousness.

- Discuss their understanding of the hazards associated with ammonia and their experience working with hazardous materials.

- Explain how they ensure compliance with safety regulations and maintain a safe work environment.

4. Prepare for Technical Questions

Candidates should expect technical questions related to the operation and maintenance of ammonia boxes. They should be prepared to discuss the different components of the system, the principles of operation, and common troubleshooting scenarios. Demonstrating a solid understanding of technical concepts will impress the interviewers and highlight their competence.

- Review the basic principles of ammonia refrigeration and gas handling.

- Be ready to explain the function of control valves, pressure gauges, and other instruments used in ammonia box operations.

5. Practice and Seek Feedback

To enhance their preparation, candidates should practice answering common interview questions. They can conduct mock interviews with a friend or family member to gain feedback on their responses and improve their delivery. By practicing, they can become more confident and articulate during the actual interview.

- Prepare for behavioral questions by using the STAR method (Situation, Task, Action, Result).

- Ask for feedback from others to identify areas for improvement.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Ammonia Box Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!