Feeling lost in a sea of interview questions? Landed that dream interview for Dye Automation Operator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Dye Automation Operator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

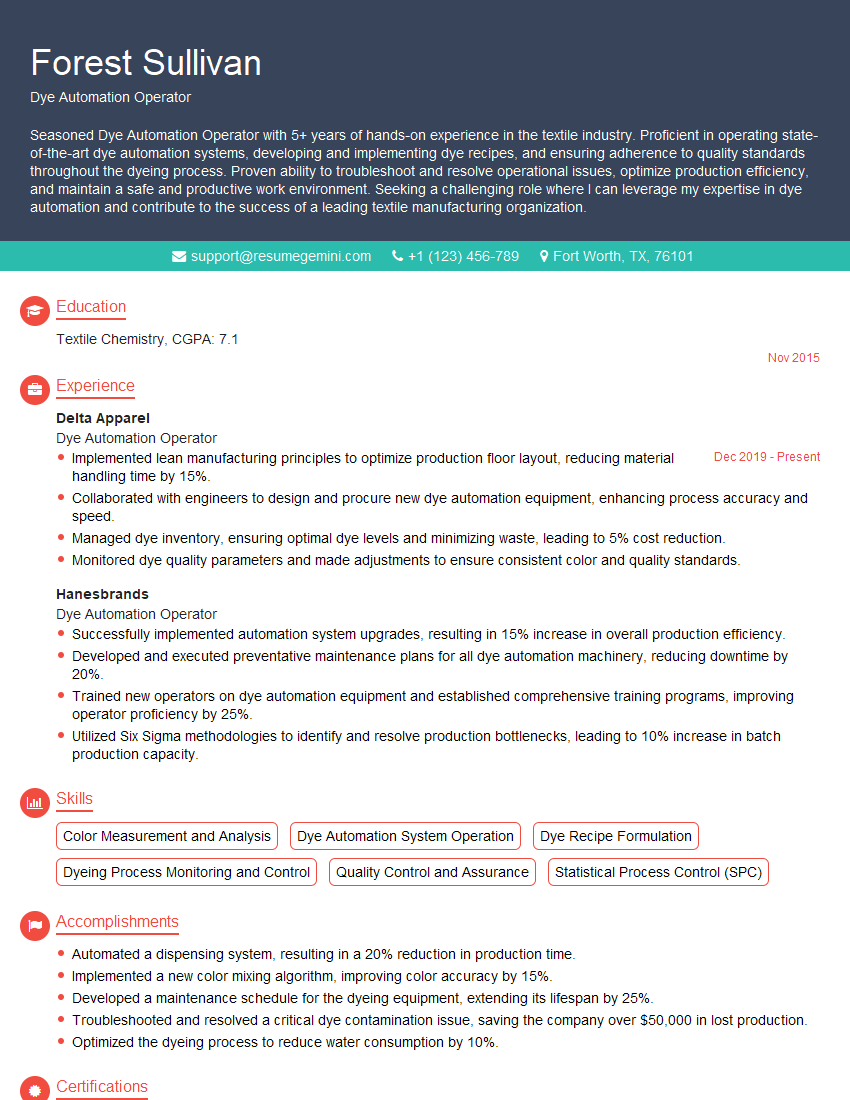

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Dye Automation Operator

1. Explain the process of dye automation in garment manufacturing?

Dye automation involves using automated machinery and computerized systems to control and manage the dyeing process in garment manufacturing. It typically involves the following steps:

- Recipe Creation: A dye recipe is developed based on the desired color, fabric type, and other parameters.

- Loading and Dispensing: Fabric or garments are loaded into the dyeing machine, and the appropriate dyes and chemicals are automatically dispensed.

- Dyeing Process: The dye cycle is controlled by the automated system, including temperature, time, and agitation.

- Monitoring and Control: Sensors and controllers monitor the dyeing process to ensure the desired color and quality are achieved.

- Unloading and Drying: The dyed fabric or garments are unloaded from the machine and dried in a controlled environment.

2. Describe the different types of dye automation systems used in textile manufacturing?

Batch Systems

- Suitable for small to medium production volumes.

- Involves loading and dyeing a specific batch of fabric or garments at a time.

Continuous Systems

- Used for high-volume production.

- Fabric or garments are moved through a series of dyeing baths in a continuous process.

3. What are the key parameters to consider when setting up a dye automation system?

- Fabric type and characteristics

- Desired color and shade

- Production capacity and batch size

- Energy efficiency and environmental considerations

- Automation level and operator skill requirements

4. How do you ensure the accuracy and consistency of dye automation processes?

- Calibration and Maintenance: Regularly calibrating and maintaining the automation system and sensors.

- Process Standardization: Developing and following standardized operating procedures for all dyeing processes.

- Quality Control: Implementing quality control measures to monitor color accuracy and fabric quality.

- Operator Training: Ensuring that operators are well-trained and knowledgeable about the system.

5. What are the common troubleshooting techniques for dye automation systems?

- Sensor Failures: Checking sensor connections and calibrations.

- Pump Issues: Inspecting pumps for blockages or leaks.

- Dye Dispensing Errors: Verifying dye recipes and checking the dispensing system.

- Temperature Control Problems: Monitoring heating and cooling systems.

- Fabric Loading Issues: Ensuring proper fabric loading to avoid entanglement or uneven dyeing.

6. How do you optimize dye automation processes for efficiency and cost reduction?

- Process Optimization: Evaluating and improving dyeing parameters to reduce cycle times and energy consumption.

- Batch Scheduling: Optimizing batch scheduling to maximize machine utilization and reduce downtime.

- Dye Inventory Management: Efficiently managing dye inventory to minimize waste and optimize purchasing.

- Predictive Maintenance: Implementing predictive maintenance techniques to identify and address potential issues before they impact production.

7. Describe the safety precautions and environmental regulations that must be followed when operating dye automation systems?

- Chemical Handling: Following safety protocols for handling dyes and chemicals.

- Equipment Safety: Ensuring proper operation and maintenance of dyeing equipment.

- Waste Management: Complying with environmental regulations for wastewater and dye disposal.

- Ventilation and Exhaust: Ensuring adequate ventilation and exhaust systems to mitigate chemical fumes.

- Personal Protective Equipment: Using appropriate personal protective equipment (PPE) during dyeing operations.

8. What are the emerging trends and advancements in dye automation technology?

- Artificial Intelligence (AI): Using AI algorithms to optimize dyeing processes and predict color outcomes.

- Robotics: Integrating robotics into dye handling and loading operations.

- Sensor Technology: Advanced sensors for real-time monitoring and control of dyeing parameters.

- Sustainable Dyeing: Focus on developing eco-friendly dyes and processes.

- Digitalization: Digital platforms for remote monitoring and data analysis.

9. How do you stay up-to-date with the latest developments in dye automation technology?

- Industry Events and Conferences: Attending industry events to interact with experts and learn about new technologies.

- Trade Publications and Journals: Reading industry publications and journals to stay informed about technological advancements.

- Online Research: Conducting research online to explore new technologies and their applications.

- Networking with Peers: Connecting with other professionals in the field to exchange knowledge and insights.

10. Describe a challenging dye automation project you worked on and how you overcame the obstacles?

In a previous role, I was involved in implementing a new continuous dye automation system for a high-volume production facility. The challenge lay in integrating the system with the existing manufacturing process and ensuring smooth transition without disrupting production.

To overcome this, I collaborated with the production team to develop a phased implementation plan. We started with a small-scale trial to test the system and identify potential issues. Based on the learnings from the trial, we gradually expanded the implementation to the entire production line. This approach allowed us to minimize disruptions and ensure a successful transition to the new system.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Dye Automation Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Dye Automation Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Dye Automation Operators are responsible for the operation and maintenance of automated dye systems in textile manufacturing facilities.

1. Machine Operation

They operate and monitor automated dyeing machines, ensuring that they are functioning properly and producing consistent results.

- Load and unload fabric or yarn into the dyeing machine.

- Set and adjust machine parameters according to production specifications.

2. Quality Control

Dye Automation Operators conduct quality control checks on the dyed fabric or yarn to ensure that it meets the required standards.

- Inspect fabric or yarn for color, shade, and appearance.

- Take corrective action if any quality issues are identified.

3. Process Optimization

They work with supervisors and technicians to improve the efficiency and productivity of the dyeing process.

- Identify areas for improvement in the dyeing process.

- Implement process modifications to reduce waste and improve quality.

4. Maintenance

Dye Automation Operators perform basic maintenance and troubleshooting on the dyeing equipment.

- Clean and lubricate machine components.

- Identify and resolve minor operational issues.

Interview Tips

To ace an interview as a Dye Automation Operator, there are several key preparation tips to keep in mind.

1. Research the Company and Role

Take the time to research the company you are applying to and the specific role of Dye Automation Operator. This will help you understand the company’s culture and values, as well as the specific requirements of the job.

- Visit the company’s website and read about their history, mission, and products or services.

- Look for news articles or industry reports that mention the company to get an idea of their reputation and current projects.

2. Practice Common Interview Questions

There are several common interview questions that you are likely to be asked for the role of Dye Automation Operator. By practicing your answers to these questions in advance, you can feel more confident and prepared during the interview.

- Tell me about your experience operating automated dyeing machines.

- How do you ensure the quality of the dyed fabric or yarn?

- What are some ways you have improved the efficiency of the dyeing process?

- Describe your experience with troubleshooting and resolving operational issues.

3. Highlight Your Skills and Experience

During the interview, be sure to highlight your skills and experience that are relevant to the role of Dye Automation Operator. Focus on your ability to operate and maintain automated dyeing machines, conduct quality control checks, and improve the efficiency of the dyeing process.

- Quantify your accomplishments with specific metrics whenever possible.

- Use examples from your previous experience to demonstrate your skills and abilities.

4. Ask Questions

Asking thoughtful questions at the end of the interview shows that you are engaged and interested in the role. It also gives you an opportunity to learn more about the company and the position.

- Ask about the company’s growth plans and future projects.

- Inquire about the training and development opportunities available for Dye Automation Operators.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Dye Automation Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!