Are you gearing up for an interview for a Dye Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Dye Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

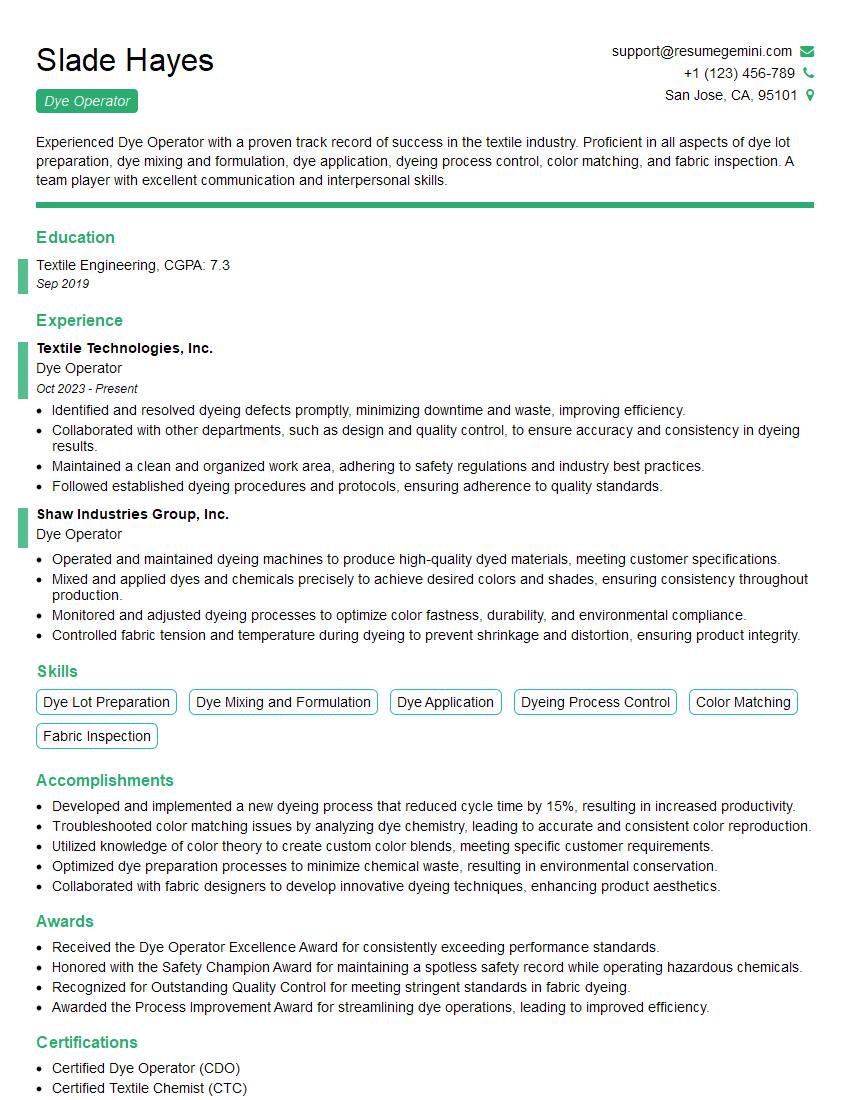

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Dye Operator

1. What are the different types of dyes used in the textile industry, and what are their unique properties?

There are numerous types of dyes used in the textile industry, each with its unique properties. Here are some common types:

- Acid Dyes: These dyes are used on materials like wool, silk, and nylon. They are known for their bright and vivid colors.

- Basic Dyes: These dyes are used on materials like cotton, rayon, and jute. They are characterized by their high color strength and low wash fastness.

- Direct Dyes: These dyes are used on materials like cotton, rayon, and cellulosic fibers. They are easy to apply and have good colorfastness properties.

- Reactive Dyes: These dyes are used on materials like cotton, wool, and silk. They form covalent bonds with the fibers, resulting in excellent colorfastness.

- Disperse Dyes: These dyes are used on materials like polyester and nylon. They are highly resistant to fading and are commonly used for synthetic fibers.

2. Explain the process of batch dyeing, including the steps involved and the factors that affect the outcome.

Dyeing Process

- Loading fabric into the dyeing machine

- Adding dye and chemicals based on the desired shade

- Controlling temperature, pH, and agitation during the dyeing cycle

- Rinsing and washing the fabric to remove excess dye and chemicals

- Drying and finishing the fabric

Factors Affecting Outcome

- Type of dye and fabric

- Dye concentration and pH

- Temperature and dyeing time

- Machine capacity and agitation

- Operator’s skill and experience

3. What are the key quality control measures implemented in a dye house to ensure the consistency of dyed products?

Maintaining consistency in dyed products is crucial. Here are some key quality control measures:

- Standard Operating Procedures (SOPs): Establishing clear and detailed SOPs for all dyeing processes.

- Color Matching: Using spectrophotometers or color matching systems to ensure accurate color reproduction.

- Fastness Testing: Conducting tests to assess the dye’s resistance to fading, washing, rubbing, and other factors.

- Visual Inspection: Regularly inspecting dyed fabrics for defects, unevenness, or shade variations.

- Data Recording and Analysis: Maintaining records of dyeing parameters, test results, and any deviations to identify areas for improvement.

4. Describe the safety precautions that must be followed when working with dyes and chemicals in a dye house environment.

Working in a dye house requires adherence to strict safety protocols:

- Personal Protective Equipment (PPE): Wearing appropriate PPE such as gloves, masks, and eye protection.

- Chemical Handling: Following proper procedures for handling and storing dyes and chemicals, including using specific equipment and minimizing exposure.

- Ventilation and Air Quality: Ensuring adequate ventilation and air quality to prevent exposure to harmful fumes.

- Waste Disposal: Disposing of dye waste and chemicals according to environmental regulations.

- Emergency Response: Knowing emergency procedures in case of spills, leaks, or accidents.

5. Explain the role of auxiliaries in the dyeing process, and discuss how they affect the quality of the dyed fabric.

Auxiliaries play a vital role in dyeing, enhancing the quality of the dyed fabric:

- Wetting Agents: Improve fabric wettability, allowing dyes to penetrate more effectively.

- Leveling Agents: Promote even distribution of dyes, preventing streaks or unevenness.

- Retarders: Control the dyeing rate, preventing premature exhaustion of dyes.

- Softeners: Improve fabric handle and feel.

- Penetrating Agents: Enhance dye penetration, especially for dense or hydrophobic fibers.

6. What are the different methods used for shade matching, and how do you ensure accuracy in the process?

Shade matching is crucial for color consistency:

- Visual Matching: Comparing dyed samples to a standard shade card.

- Spectrophotometer Matching: Using a spectrophotometer to measure and compare color values.

- Computer-Aided Matching: Employing software to analyze color data and formulate dye recipes.

Accuracy in shade matching is ensured by:

- Using calibrated equipment

- Following standardized procedures

- Conducting multiple tests and verifications

7. How do you troubleshoot common dyeing problems, such as uneven dyeing, color bleeding, and shade variations?

Troubleshoot and resolve dyeing issues:

- Uneven Dyeing: Check dye concentration, temperature, agitation, and fabric preparation.

- Color Bleeding: Assess dye fixation, pH, and rinsing procedures.

- Shade Variations: Analyze dye lot, water quality, and auxiliary usage.

8. Describe the environmental regulations and sustainability practices that are relevant to the dyeing industry.

Adhering to environmental regulations and sustainability practices is essential:

- Wastewater Treatment: Implementing systems to treat and minimize the environmental impact of dye wastewater.

- Chemical Management: Using eco-friendly dyes and chemicals, and reducing hazardous waste.

- Energy Conservation: Optimizing energy consumption in dyeing processes and equipment.

- Compliance with Regulations: Meeting or exceeding environmental standards and regulations.

9. How do you stay up-to-date with the latest advancements and best practices in the dyeing industry?

Maintaining knowledge and skills is important:

- Attending Industry Events and Conferences: Participating in workshops and seminars.

- Reading Technical Journals and Publications: Staying informed about new technologies and techniques.

- Networking with Industry Professionals: Exchanging knowledge and experiences.

- Continuous Training and Development: Seeking opportunities for professional growth.

10. What are your strengths and weaknesses as a Dye Operator?

Here are some strengths and weaknesses to consider:

Strengths

- Proficient in various dyeing techniques and equipment.

- Strong understanding of color theory and chemistry.

- Excellent attention to detail and quality control.

- Ability to work independently and as part of a team.

- Commitment to safety and environmental regulations.

Weaknesses

- Limited experience with certain types of dyes or fabrics.

- Need to improve efficiency in certain aspects of the dyeing process.

- Open to constructive criticism and actively seeking ways to improve skills.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Dye Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Dye Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Dye Operators play a vital role in the textile industry, undertaking various critical responsibilities to ensure the successful dyeing of fabrics. Their key job functions include:

1. Dyeing Process Management

Dye Operators are responsible for the entire dyeing process, from receiving fabrics to preparing dye solutions and operating dyeing machines. They monitor the dyeing process, make necessary adjustments, and ensure that fabrics meet the desired color specifications.

- Prepare, mix, and apply dyes and chemical solutions based on instructions

- Operate and monitor dyeing machines, adjusting settings for temperature, pressure, and dyeing time

- Control the dyeing process to achieve the desired color, shade, and fastness

2. Fabric Inspection and Quality Control

Dye Operators inspect fabrics before and after dyeing to ensure that they meet quality standards. They assess the color uniformity, shade consistency, and overall appearance of fabrics, identifying and correcting any defects or inconsistencies.

- Inspect fabrics for defects, streaks, or uneven dyeing

- Conduct shade matching and color comparison to ensure accuracy

- Identify and resolve any quality issues in consultation with supervisors or technicians

3. Equipment Maintenance and Troubleshooting

Dye Operators are responsible for maintaining and troubleshooting dyeing equipment to ensure smooth and efficient operations. They perform regular inspections, clean and lubricate machines, and identify potential issues before they escalate.

- Perform routine maintenance tasks, such as cleaning, lubrication, and equipment adjustments

- Troubleshoot and diagnose equipment problems, identifying and resolving issues promptly

- Work closely with maintenance technicians for major repairs or equipment upgrades

4. Safety and Environmental Compliance

Dye Operators prioritize safety and environmental compliance in their work. They adhere to established safety protocols, wear appropriate protective gear, and dispose of chemicals and waste responsibly.

- Follow safety procedures and wear protective gear to minimize risks

- Handle and dispose of chemicals and dyes according to environmental regulations

- Maintain a clean and organized work area to ensure safety and efficiency

Interview Tips

Preparing thoroughly can increase your chances of impressing the interviewer and landing the Dye Operator position. Consider the following tips to enhance your interview performance:

1. Research the Company and Industry

Before the interview, research the specific company you’re applying to, as well as the textile industry as a whole. This demonstrates your interest and enthusiasm for the role and the sector.

- Visit the company website to learn about their products, mission, and values

- Explore industry publications and news articles to stay up-to-date on current trends and best practices

2. Highlight Relevant Skills and Experience

During the interview, emphasize your skills and experience that are directly relevant to the Dye Operator role. Quantify your accomplishments and provide specific examples that showcase your capabilities.

- Discuss your hands-on experience in fabric dyeing and quality control

- Mention any knowledge of different dyeing techniques and dye chemistry

- Highlight your ability to work independently and as part of a team

3. Demonstrate Attention to Detail and Quality

Dye Operators must have a keen eye for detail and a commitment to quality. Showcase these traits throughout the interview. For instance, prepare questions that demonstrate your understanding of quality control processes and your commitment to delivering high-quality results.

- Ask about the company’s quality standards and how they ensure customer satisfaction

- Discuss your experience in identifying and resolving quality issues promptly

4. Anticipate Common Interview Questions

Preparing for common interview questions can help you feel more confident and articulate during the interview. Some typical questions for Dye Operator positions include:

- Tell us about your experience in fabric dyeing and quality control?

- How do you handle a situation where fabrics do not meet the desired color specifications?

- What are your strengths and weaknesses as a Dye Operator?

5. Be Prepared to Answer Technical Questions

Be prepared to answer technical questions that assess your knowledge of dyeing processes and equipment. These questions may cover topics such as:

- Different types of dyes and their properties

- Dyeing machine operation and troubleshooting

- Color theory and color matching techniques

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Dye Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.