Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Dye-Tank Tender position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

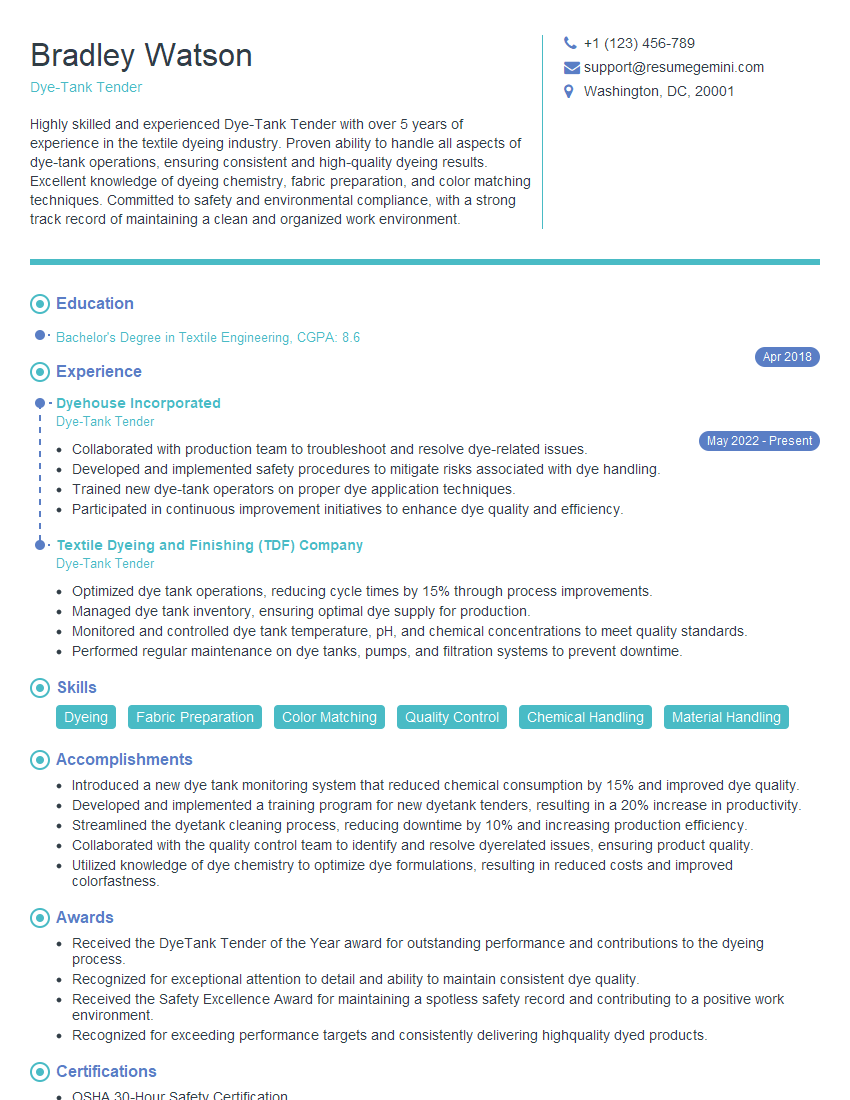

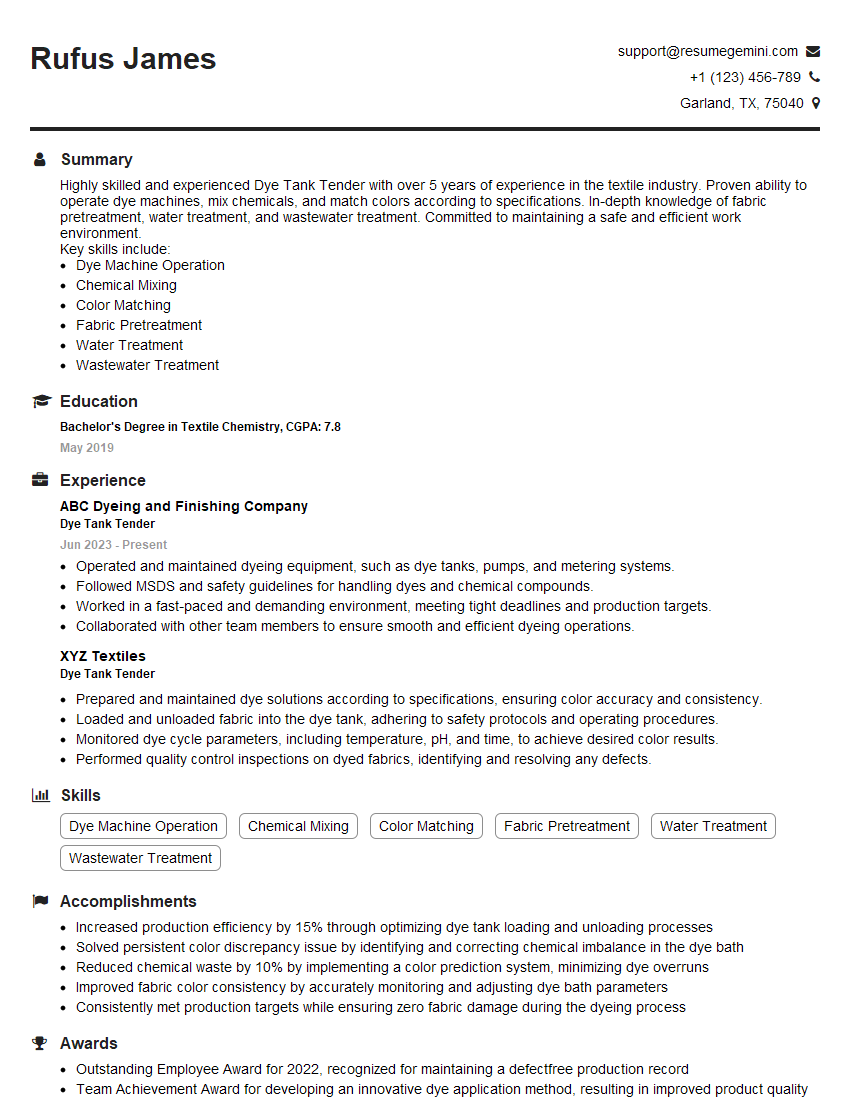

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Dye-Tank Tender

1. How do you determine the correct dye formula for a particular fabric?

To determine the correct dye formula for a particular fabric, I start by identifying the fiber content of the fabric. Once I know the fiber content, I can refer to a dye compatibility chart or consult with a dye expert. I also consider the desired color, lightfastness, and washfastness requirements.

2. What are the steps involved in preparing the dye bath?

Adding Chemicals

- First, I add the necessary chemicals to the dye bath, including the dye, salt, and leveling agent.

- I carefully measure and weigh each chemical to ensure the correct proportions.

Adjusting Temperature and pH

- Next, I adjust the temperature of the dye bath according to the dye manufacturer’s instructions.

- I also adjust the pH of the dye bath using acids or bases.

3. How do you load the fabric into the dye tank?

I carefully load the fabric into the dye tank, ensuring that it is evenly distributed and free of wrinkles. I use a hoist or winch to lower the fabric into the dye bath.

4. What are the process parameters that need to be monitored during dyeing?

- Temperature

- pH

- Time

- Liquor ratio

- Agitation

5. How do you determine when the dyeing process is complete?

I perform shade matching to determine when the dyeing process is complete. I compare the dyed fabric to a standard sample and make adjustments to the dye bath as needed.

6. What are the common defects that can occur during dyeing and how do you prevent them?

- Barring: Caused by uneven dyeing. Prevented by ensuring proper agitation and liquor circulation.

- Bronzing: Caused by oxidation of the dye. Prevented by adding antioxidants to the dye bath.

- Crocking: Caused by poor dye fixation. Prevented by using the correct dye and dyeing process for the fabric.

7. What is the importance of quality control in dyeing?

Quality control is crucial in dyeing to ensure that the dyed fabric meets the desired specifications. It involves checking the color, lightfastness, and washfastness of the fabric.

8. What are the safety precautions that need to be followed while working with dyes?

- Wear appropriate protective gear, including gloves, mask, and apron.

- Handle dyes with care and avoid contact with skin and eyes.

- Follow the manufacturer’s instructions for proper disposal of dyes.

9. How do you stay updated on the latest dyeing techniques and technologies?

I attend industry conferences, read trade publications, and consult with dye suppliers to stay informed about the latest dyeing techniques and technologies.

10. What are your strengths and weaknesses as a Dye-Tank Tender?

Strengths:

- Excellent knowledge of dyeing processes and techniques.

- Strong attention to detail and quality control.

- Ability to work independently and as part of a team.

Weaknesses:

- Limited experience with digital printing techniques.

- Still developing proficiency in troubleshooting complex dyeing issues.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Dye-Tank Tender.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Dye-Tank Tender‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Dye-Tank Tenders play a crucial role in textile manufacturing processes by operating and maintaining dye tanks to achieve the desired color and quality of fabrics and garments.

1. Dye Tank Operations

Loading and unloading fabrics into and out of dye tanks

- Measuring and adding dyes, chemicals, and other materials to create the desired color according to specifications

- Regulating temperature, pH levels, and other dyeing parameters to ensure proper color development

2. Monitoring and Control

Monitoring the dyeing process to identify any deviations from specifications

- Taking samples to check color fastness and other quality parameters

- Adjusting process parameters and making necessary corrections to achieve the desired results

3. Maintenance and Troubleshooting

Performing routine maintenance and cleaning of dye tanks and associated equipment

- Inspecting and repairing any equipment malfunctions or leaks

- Maintaining a clean and safe work environment

4. Record Keeping

Maintaining accurate records of dyeing parameters, materials used, and quality control results

- Communicating with supervisors and other departments as needed to provide updates on progress and any issues encountered

- Adhering to safety protocols and environmental regulations

Interview Tips

Preparing thoroughly for an interview can significantly increase your chances of success. Here are some valuable tips to help you ace your interview for a Dye-Tank Tender position:

1. Research the Company and Position

Familiarize yourself with the company’s history, values, and the specific requirements of the Dye-Tank Tender role.

- Visit the company’s website and social media pages to gather information

- Read industry articles and news to stay updated on the latest trends and technologies

2. Highlight Relevant Experience and Skills

Emphasize your previous experience operating dye tanks and your understanding of dyeing processes.

- Use specific examples to demonstrate your ability to monitor and control dyeing parameters, troubleshoot equipment issues, and maintain a clean and safe work environment

- Quantify your accomplishments whenever possible to showcase your impact

3. Be Prepared for Technical Questions

Anticipate questions related to the technical aspects of dyeing, such as:

- Describe the different types of dyes and their applications

- Explain the key parameters that affect the dyeing process and how to control them

- Discuss the importance of color matching and how to achieve accurate color reproduction

4. Emphasize Safety and Quality

Dye-Tank Tenders play a crucial role in maintaining a safe and high-quality production environment.

- Highlight your commitment to safety and your knowledge of industry regulations

- Explain how you ensure the quality of dyed fabrics and garments

- Describe your approach to continuous improvement and process optimization

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Dye-Tank Tender interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!