Are you gearing up for a career in Dyed Yarn Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Dyed Yarn Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

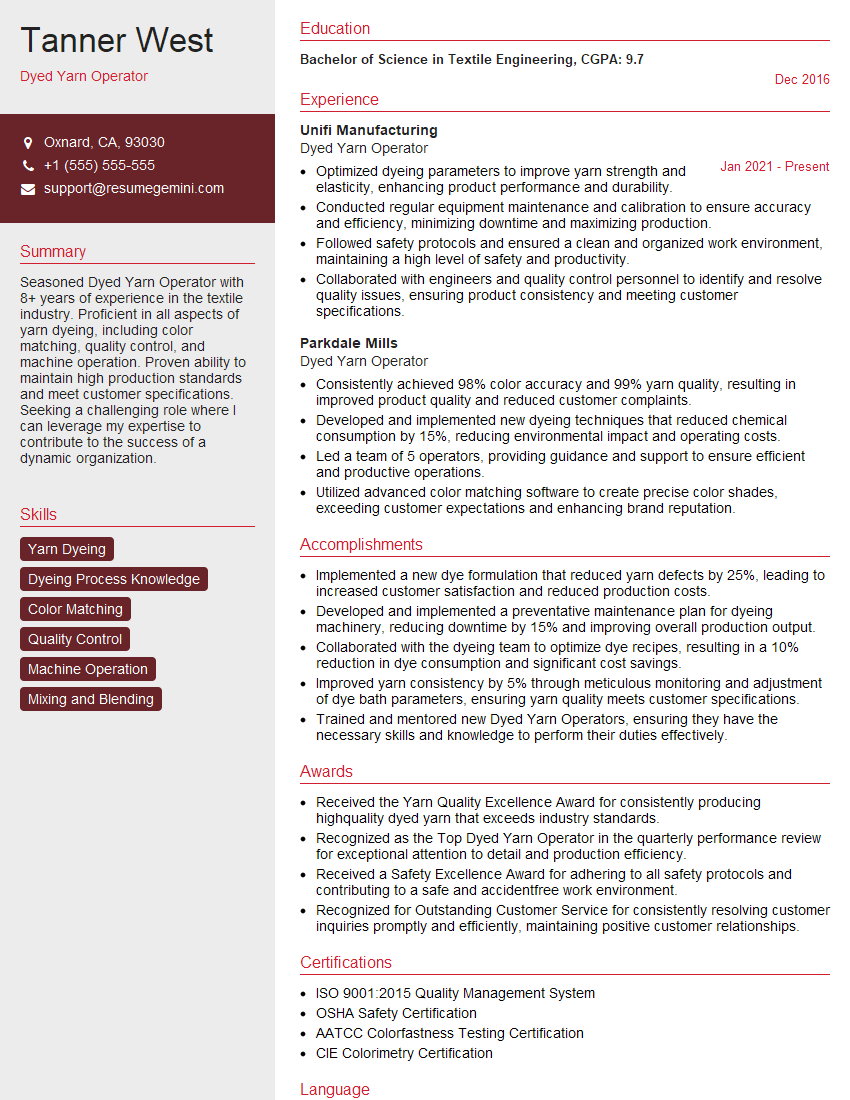

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Dyed Yarn Operator

1. What are the different types of yarn dyeing methods used in textile industry?

There are various yarn dyeing methods commonly used in the textile industry, including:

- Stock dyeing: Dyeing fibers or yarn in loose form before spinning into yarn.

- Yarn dyeing: Dyeing yarn in hank or package form after spinning.

- Piece dyeing: Dyeing fabric after it has been woven or knitted.

- Garment dyeing: Dyeing finished garments.

- Solution dyeing: Adding dyes to the polymer solution before fiber extrusion.

2. Explain the process of hank dyeing in detail.

Hank dyeing steps:

- Winding yarn into hanks

- Scouring to remove impurities

- Preparing the dye bath

- Dyeing the hanks

- Rinsing and washing

- Drying

Hank dyeing advantages:

- Good penetration and levelness

- Suitable for a wide range of fibers

- Can achieve various shades and patterns

3. What are the key factors to consider when selecting dyes for yarn dyeing?

Important factors to consider when selecting dyes for yarn dyeing include:

- Fiber type and composition

- Desired shade and colorfastness requirements

- Dyeing method and equipment available

- Cost and availability of dyes

- Environmental regulations and sustainability concerns

4. How do you ensure color consistency in yarn dyeing?

To ensure color consistency in yarn dyeing, it is essential to:

- Use standardized dyeing procedures and recipes

- Control dyeing parameters such as temperature, pH, and time

- Monitor the dye bath concentration regularly

- Perform shade matching and color correction if necessary

- Implement quality control measures to ensure consistency

5. What are the common defects associated with yarn dyeing and how can they be prevented?

Common defects in yarn dyeing and their prevention methods include:

- Uneven dyeing: Can be prevented by ensuring proper agitation, temperature control, and dye penetration.

- Color bleeding: Can be prevented by using dyes with good washfastness, controlling pH, and adding dye fixatives.

- Spots or streaks: Can be prevented by removing impurities, using clean equipment, and maintaining proper dyeing conditions.

- Shade variation: Can be prevented by using standardized procedures, controlling dyeing parameters, and performing shade matching.

6. What is the role of auxiliaries in yarn dyeing?

Auxiliaries play various roles in yarn dyeing, including:

- Wetting agents: Enhance dye penetration and levelness.

- Dispersing agents: Prevent dye agglomeration and promote even distribution.

- Leveling agents: Control dye uptake and prevent unevenness.

- Retarders: Slow down the dyeing rate to improve color depth and penetration.

- Fixatives: Improve dye fastness and prevent color bleeding.

7. How do you troubleshoot common problems that occur during yarn dyeing?

To troubleshoot common problems in yarn dyeing, it is important to:

- Identify the problem and its potential causes

- Check dyeing parameters, equipment, and materials

- Adjust dyeing conditions, such as temperature, pH, or time

- Use different dyes or auxiliaries if necessary

- Perform shade matching and color correction to achieve desired results

8. What are the safety precautions that must be followed during yarn dyeing?

Essential safety precautions in yarn dyeing include:

- Wearing appropriate protective gear, including gloves, masks, and aprons

- Handling chemicals with care and following MSDS guidelines

- Maintaining a clean and well-ventilated work area

- Using proper equipment and following safety protocols

- Being aware of potential hazards, such as spills, leaks, or explosions

9. How do you stay updated with the latest advancements and best practices in yarn dyeing?

To stay updated with advancements in yarn dyeing, I:

- Attend industry conferences and exhibitions

- Read technical articles and publications

- Participate in online forums and discussions

- Network with experts and professionals in the field

- Explore new technologies and products from suppliers

10. What are your strengths and weaknesses as a Dyed Yarn Operator?

Strengths:

- Strong understanding of yarn dyeing principles and processes

- Experience in operating various dyeing machines and equipment

- Ability to achieve consistent and high-quality dyed yarn

- Excellent problem-solving and troubleshooting skills

- Meticulous attention to detail and quality control

Weaknesses:

- Limited experience with certain specialized dyeing techniques

- Need to improve my efficiency in handling large-scale dyeing operations

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Dyed Yarn Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Dyed Yarn Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Dyed Yarn Operators are responsible for the operation of dyeing machines, which apply color to yarn used in the production of textiles. Their duties include:

1. Operating Dyeing Machines

Operate a variety of dyeing machines, including skein, package, and beam dyeing machines.

- Load and unload yarn into and out of machines.

- Start and stop machines.

- Monitor machine operation and make adjustments as needed.

2. Preparing Dye Solutions

Prepare dye solutions according to specified recipes.

- Weigh and measure dyes and chemicals.

- Mix dyes and chemicals with water.

- Adjust pH and temperature of dye solutions.

3. Dyeing Yarn

Dye yarn according to specified color recipes.

- Monitor dye cycle and make adjustments as needed.

- Rinse and dry dyed yarn.

4. Quality Control

Inspect dyed yarn for quality.

- Check for color accuracy.

- Check for any defects.

- Report any quality issues to supervisors.

Interview Tips

Preparing for an interview for a Dyed Yarn Operator position can help you make a good impression on the hiring manager. Here are some tips to help you ace the interview:

1. Research the Company and the Position

Take the time to research the company you’re interviewing with and the specific position you’re applying for. This will help you understand the company’s culture, values, and what they’re looking for in a Dyed Yarn Operator.

- Visit the company’s website.

- Read news articles and press releases about the company.

- Talk to people in your network who work for the company.

2. Practice Your Answers to Common Interview Questions

There are some common interview questions that you’re likely to be asked, such as “Tell me about your experience operating dyeing machines” or “How do you ensure the quality of the dyed yarn?” It’s helpful to practice your answers to these questions in advance so that you can deliver them confidently and clearly.

- Use the STAR method to answer questions.

- Be specific and provide examples.

- Quantify your accomplishments whenever possible.

3. Dress Professionally and Be On Time

First impressions matter, so it’s important to dress professionally for your interview. You should also arrive on time, or even a few minutes early. This shows the interviewer that you’re respectful of their time and that you’re serious about the job.

4. Be Enthusiastic and Positive

A positive attitude can go a long way in an interview. Be enthusiastic about the job and the company, and be sure to convey your passion for dyeing yarn. This will show the interviewer that you’re excited about the opportunity and that you’d be a valuable asset to their team.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Dyed Yarn Operator, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Dyed Yarn Operator positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.