Are you gearing up for an interview for a Rotary Drum Dyer position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Rotary Drum Dyer and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

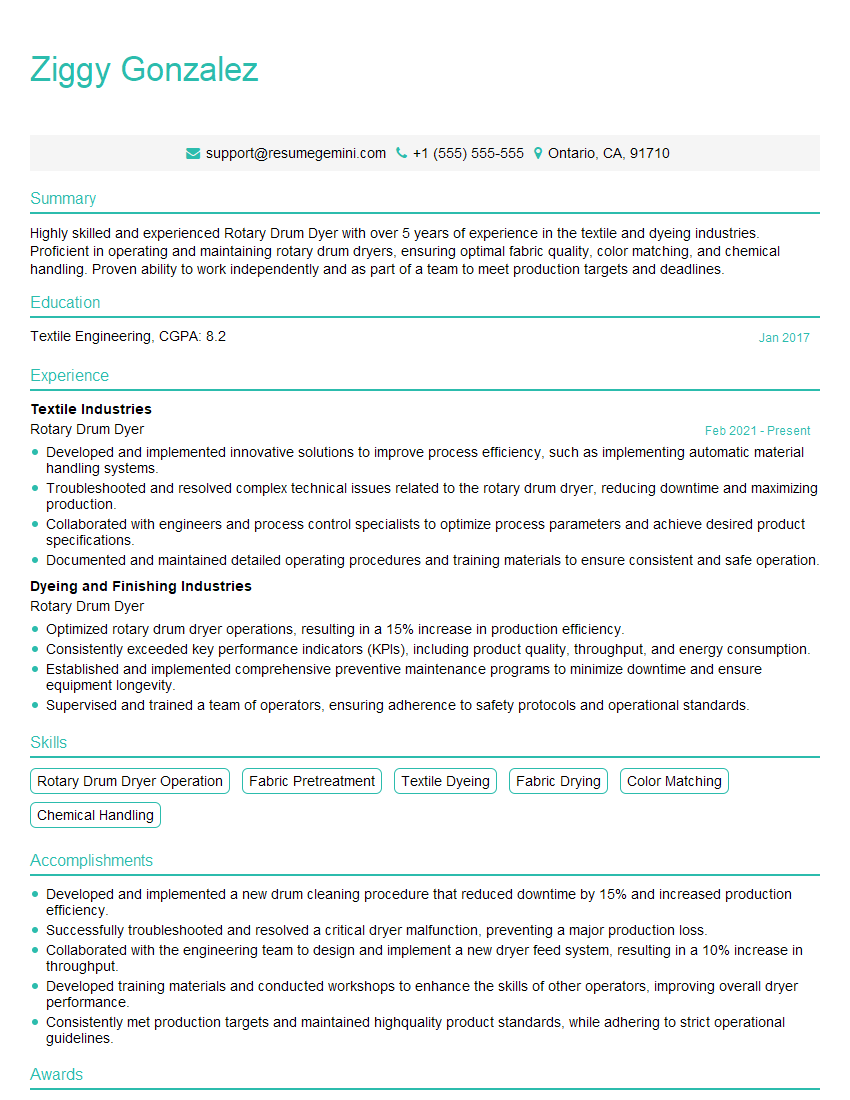

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Rotary Drum Dyer

1. Describe the working principle of a rotary drum dryer.

- Rotary drum dryers are cylindrical vessels that rotate on their horizontal axis.

- Wet materials are fed into the dryer at one end and are conveyed through the dryer by the rotation of the drum.

- Hot air or other gases are passed through the dryer in the same direction as the material flow or in counter-current direction.

- The material is lifted and showered through the hot gas stream, allowing for efficient heat and mass transfer.

- As the material moves through the dryer, moisture is evaporated and removed from the air stream by an exhaust system.

2. What are the key design factors to consider when selecting a rotary drum dryer?

Factors to consider for selecting a rotary drum dryer:

- Drying capacity and required throughput

- Material properties (particle size, moisture content, density, stickiness)

- Heat source and temperature requirements

- Gas flow rate and direction

- Drum size, speed, and material

- Heat transfer efficiency

- Energy consumption

- Space constraints

- Maintenance and accessibility

3. How do you ensure uniform drying and prevent product damage in a rotary drum dryer?

- Uniform feeding of material into the dryer

- Control of drum speed and residence time

- Proper air distribution and temperature regulation

- Use of internal flights or lifters to enhance mixing

- Monitoring of temperature and moisture content at different points in the dryer

- Avoiding overloading or underloading the dryer

- Regular maintenance and inspection of equipment

4. Explain the different types of heat sources used in rotary drum dryers.

- Direct-fired dryers: Burners or furnaces supply hot gases directly into the dryer.

- Indirect-fired dryers: Heat is transferred to the air or other gases through a heat exchanger, which is then passed through the dryer.

- Steam-heated dryers: Steam is used as the heat source, which is passed through coils or jackets inside the dryer.

- Electrical dryers: Electrical heaters are used to generate hot air or gases.

5. How do you handle and prevent dust and emissions from a rotary drum dryer?

- Use of cyclones or bag filters to remove particulate matter from the exhaust air

- Wet scrubbers or electrostatic precipitators for additional emission control

- Proper sealing of the dryer and exhaust system to prevent fugitive emissions

- Regular cleaning and maintenance of the dryer and air pollution control equipment

- Compliance with environmental regulations and standards

6. Describe the maintenance procedures for a rotary drum dryer.

- Regular lubrication of bearings and gears

- Inspection and replacement of seals and gaskets

- Monitoring and adjustment of chain or belt tension

- Cleaning and inspection of the drum interior and flights

- Calibration and maintenance of temperature and moisture sensors

- Preventive maintenance to identify and address potential issues early

7. What troubleshooting steps would you take if the rotary drum dryer is not drying the material effectively?

- Check the temperature and air flow settings

- Ensure proper material feed rate and distribution

- Inspect the drum for damage or wear

- Check the air filters and exhaust system for blockages

- Monitor the moisture content of the dried material

- Adjust the residence time or drum speed if necessary

8. How does the use of computational fluid dynamics (CFD) modeling benefit the design and optimization of rotary drum dryers?

- CFD modeling provides detailed information about the airflow patterns, temperature distribution, and moisture removal within the dryer.

- It helps optimize the design of the drum, flights, and air distribution system to enhance drying efficiency.

- CFD modeling can also predict and mitigate potential problems such as uneven drying, product damage, or dust accumulation.

- It enables the evaluation of different operating conditions and scenarios to identify the optimal settings for the dryer.

9. Describe the key performance indicators (KPIs) used to evaluate the performance of a rotary drum dryer.

- Drying efficiency (percentage of moisture removed)

- Throughput capacity (tons of material dried per hour)

- Energy consumption (kWh per ton of material dried)

- Product quality (moisture content, uniformity, particle size)

- Maintenance costs and downtime

- Environmental compliance (dust and emission levels)

10. What are the latest advancements in rotary drum dryer technology?

- Use of advanced materials for improved durability and heat transfer

- Integration of sensors and automation for real-time monitoring and control

- Development of hybrid dryers combining different heat sources or drying techniques

- Focus on energy efficiency and sustainability

- Exploration of new applications and industries for rotary drum dryers

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Rotary Drum Dyer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Rotary Drum Dyer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Rotary Drum Dyers play a vital role in the manufacturing process, responsible for transforming raw materials into high-quality products. Their key job responsibilities revolve around ensuring efficient and safe operation of the rotary drum dyeing equipment while maintaining a high level of product quality.

1. Drum Operation Management

Operate and control the rotary drum dyer to achieve desired dyeing results. Monitor drum temperature, pressure, and other process parameters to maintain optimal dyeing conditions.

- Manage dye loading and unloading processes to ensure accurate quantities and minimize material loss.

- Carry out periodic maintenance and troubleshooting to ensure smooth operation of the equipment.

2. Fabric Preparation and Dyeing

Prepare fabrics for dyeing by pre-treating and conditioning them to enhance dye absorption. Conduct shade matching tests to determine the correct dye concentrations.

- Monitor dye cycles and adjust process parameters as needed to achieve the desired color and quality.

- Ensure proper rinsing and drying of dyed fabrics to meet quality standards and specifications.

3. Quality Control and Assurance

Perform regular quality checks on dyed fabrics to assess colorfastness, shade consistency, and overall appearance.

- Maintain accurate records of dyeing processes and results to ensure traceability and compliance with quality standards.

- Work closely with the quality assurance team to resolve any quality issues and improve dyeing processes.

4. Safety and Compliance

Adhere to all safety protocols and regulations related to the operation of rotary drum dyers and handling of chemicals.

- Wear appropriate personal protective equipment (PPE) and follow established safety procedures.

- Maintain a clean and organized work area to prevent accidents and ensure efficient operations.

Interview Preparation Tips

Ace the interview for the Rotary Drum Dyer position by showcasing your technical expertise, problem-solving abilities, and commitment to quality.

1. Research the Industry and Company

Demonstrate your knowledge of the textile dyeing industry and the specific company you’re applying to. Understand their products, processes, and market position.

- Visit the company’s website and social media pages to gather information.

- Read industry publications and articles to stay up-to-date on the latest trends and technologies.

2. Highlight Your Technical Skills

Emphasize your proficiency in operating rotary drum dyeing equipment. Discuss your experience in managing process parameters, troubleshooting, and ensuring product quality.

- Provide specific examples of how you have optimized dyeing processes and achieved desired results.

- Showcase your knowledge of different types of fabrics and their dyeing characteristics.

3. Demonstrate Your Problem-Solving Abilities

Highlight your ability to identify and resolve problems that may arise during the dyeing process. Discuss how you have handled unexpected challenges and found innovative solutions.

- Prepare examples of situations where you had to analyze data, troubleshoot equipment, or adjust process parameters to achieve optimal outcomes.

- Explain how your problem-solving approach has contributed to improving efficiency and quality.

4. Emphasize Your Commitment to Quality

Convince the interviewer of your commitment to producing high-quality dyed fabrics. Explain your understanding of color matching, shade consistency, and quality control procedures.

- Discuss your experience in implementing and maintaining quality assurance systems.

- Highlight your attention to detail and your ability to meet or exceed quality standards.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Rotary Drum Dyer interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!