Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Band Cutter position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

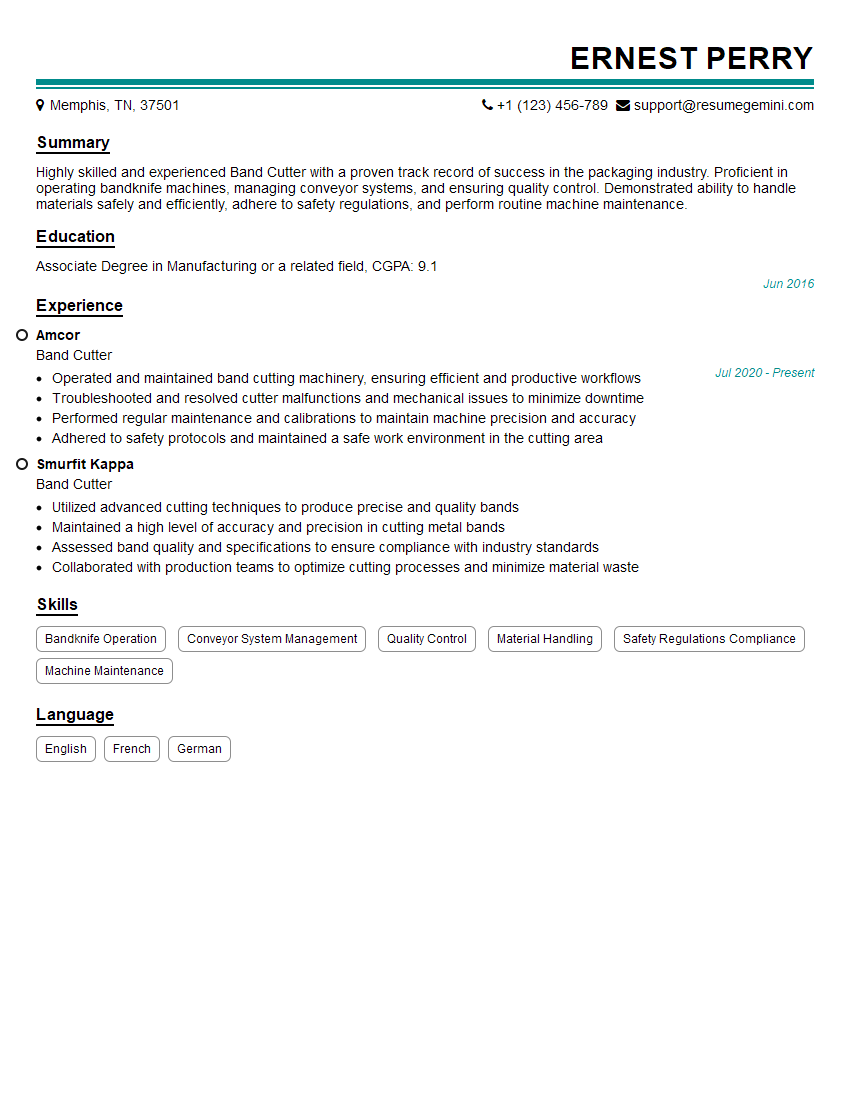

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Band Cutter

1. Explain the process of cutting steel bands?

The process of cutting steel bands involves several steps:

- Preparation: Inspect the steel band to identify any defects or damage. Ensure that the cutting equipment is in good working order.

- Marking: Mark the desired cutting point on the steel band using a tape measure or marking tool.

- Cutting: Use a band saw, shear, or other cutting tool to cut the steel band cleanly and precisely at the marked point.

- Deburring: Remove any sharp edges or burrs from the cut surface using a file or deburring tool.

- Inspection: Inspect the cut steel band to ensure it meets the required specifications and is free from any defects.

2. What types of cutting tools are used to cut steel bands?

Common cutting tools used for steel bands include:

- Band saw: A power tool that uses a continuous blade to cut through the steel band.

- Shear: A hand-operated or hydraulic tool that uses two blades to cut the steel band.

- Cold saw: A circular saw with carbide-tipped blades specifically designed for cutting steel.

3. What factors influence the choice of cutting tool for steel bands?

The choice of cutting tool depends on several factors:

- Thickness of the steel band: Thicker bands require more powerful cutting tools.

- Material of the steel band: Different steel alloys have varying hardness and require specific cutting tools.

- Desired cut quality: Some tools provide cleaner cuts than others.

- Production volume: High-volume operations may require more efficient cutting tools.

- Cost and availability: Tool cost and availability can also influence the choice.

4. How do you ensure the accuracy of steel band cuts?

To ensure accuracy:

- Accurate marking: Use precise measuring tools and mark the cutting point carefully.

- Proper tool alignment: Align the cutting tool perpendicular to the steel band.

- Adequate clamping: Secure the steel band firmly to prevent movement during cutting.

- Sharp cutting blades: Dull blades can result in uneven or inaccurate cuts.

5. Describe the safety precautions required when cutting steel bands

Safety is paramount:

- Wear protective gear: Safety glasses, gloves, and earplugs.

- Inspect equipment: Check cutting tools for any damage or defects.

- Secure the workpiece: Clamp the steel band firmly to prevent movement.

- Control the cutting force: Avoid excessive force that could cause the blade to break.

- Handle sharp edges: Use caution when handling cut steel bands to avoid cuts.

6. How do you maintain and calibrate cutting tools for steel bands?

Maintenance and calibration ensure optimal performance:

- Regular cleaning: Remove debris and lubricants from cutting tools.

- Sharpening: Sharpen blades as per manufacturer’s recommendations.

- Lubrication: Lubricate moving parts to reduce friction and wear.

- Calibration: Use a calibration fixture to ensure accurate cutting.

7. What is the importance of selecting the correct blade for cutting steel bands?

Blade selection is crucial:

- Material: Choose blades made of high-quality steel alloys that can withstand the hardness of steel bands.

- Tooth count: Higher tooth counts result in finer cuts, while lower tooth counts provide faster cutting.

- Tooth geometry: The shape of the teeth influences cut quality and blade life.

8. Explain the different types of steel band cutting machines.

Machines vary in their capabilities:

- Manual band cutters: Hand-operated devices for low-volume applications.

- Semi-automatic band cutters: Powered machines that require manual loading and unloading of steel bands.

- Fully automatic band cutters: Automated systems that integrate cutting, stacking, and other processes.

9. Describe the factors that affect the cutting speed of steel bands.

Cutting speed is influenced by:

- Blade sharpness: Sharper blades cut faster.

- Blade tension: Proper blade tension prevents vibration and improves cut quality.

- Cutting force: Excessive force can slow down cutting.

- Material thickness: Thicker bands require slower cutting speeds.

10. How do you troubleshoot common problems encountered in steel band cutting?

Troubleshooting is essential for efficient operations:

- Uneven cuts: Check blade alignment, tension, and sharpness.

- Excessive burrs: Use a deburring tool or adjust cutting parameters.

- Blade breakage: Inspect the blade for defects, ensure proper tension, and avoid excessive cutting force.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Band Cutter.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Band Cutter‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Band cutters are responsible for cutting and preparing bands for use in a variety of applications, such as packaging, printing, and construction. They may also be responsible for operating and maintaining the equipment used to cut the bands.

1. Cutting Bands

Band cutters use a variety of tools to cut bands, including knives, saws, and shears. The type of tool used will depend on the material of the band and the desired cut. Band cutters must be able to cut bands to precise specifications.

- Cut bands to precise specifications using a variety of tools, including knives, saws, and shears

- Select the appropriate tool for the material of the band and the desired cut

- Ensure that the bands are cut to the correct length and width

2. Preparing Bands

Once the bands have been cut, they must be prepared for use. This may involve punching holes in the bands, attaching labels, or applying other treatments. Band cutters must be able to prepare bands quickly and efficiently.

- Prepare bands for use by punching holes, attaching labels, or applying other treatments

- Ensure that the bands are prepared to the correct specifications

- Work quickly and efficiently to prepare bands for use

3. Operating and Maintaining Equipment

Band cutters may also be responsible for operating and maintaining the equipment used to cut the bands. This equipment may include saws, shears, and other machinery. Band cutters must be able to operate the equipment safely and efficiently.

- Operate and maintain the equipment used to cut bands

- Ensure that the equipment is operating safely and efficiently

- Troubleshoot and repair equipment problems

- Maintain a clean and organized work area

4. Quality Control

Band cutters are responsible for ensuring that the bands they produce meet the required quality standards. They may inspect the bands for defects and reject any bands that do not meet the standards.

- Inspect bands for defects and reject any bands that do not meet the standards

- Ensure that the bands meet the required quality standards

- Maintain a record of quality control inspections

Interview Tips

Interviews can be tough, but there are a few things you can do to prepare and improve your chances of success.

1. Research the Company and the Position

Before you go to your interview, take some time to research the company and the position you are applying for. This will help you understand the company’s culture, what they are looking for in a candidate, and what you can expect in the role.

- Visit the company’s website and social media pages

- Read articles and news stories about the company

- Talk to people who work at the company, if possible

2. Practice Your Answers to Common Interview Questions

There are a few common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It is helpful to practice your answers to these questions in advance so that you can deliver them confidently and clearly.

- Think about your experiences and skills and how they relate to the job you are applying for

- Practice your answers out loud so that you can become more comfortable with them

- Ask a friend or family member to give you feedback on your answers

3. Be Prepared to Ask Questions

Interviews are a two-way street, and you should be prepared to ask the interviewer questions as well. This shows that you are interested in the company and the position, and that you are taking the interview seriously.

- Prepare a list of questions to ask the interviewer before you go to the interview

- Ask questions about the company, the position, and the interviewer’s experience

- Be respectful and professional when asking questions

4. Dress Professionally and Arrive on Time

First impressions matter, so it is important to dress professionally for your interview. You should also arrive on time, or even a few minutes early. This shows that you are respectful of the interviewer’s time and that you are serious about the position.

- Choose clothing that is appropriate for the company culture and the position you are applying for

- Make sure your clothes are clean and pressed

- Arrive on time, or even a few minutes early, for your interview

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Band Cutter, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Band Cutter positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.