Are you gearing up for an interview for a Corduroy Cutter Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Corduroy Cutter Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

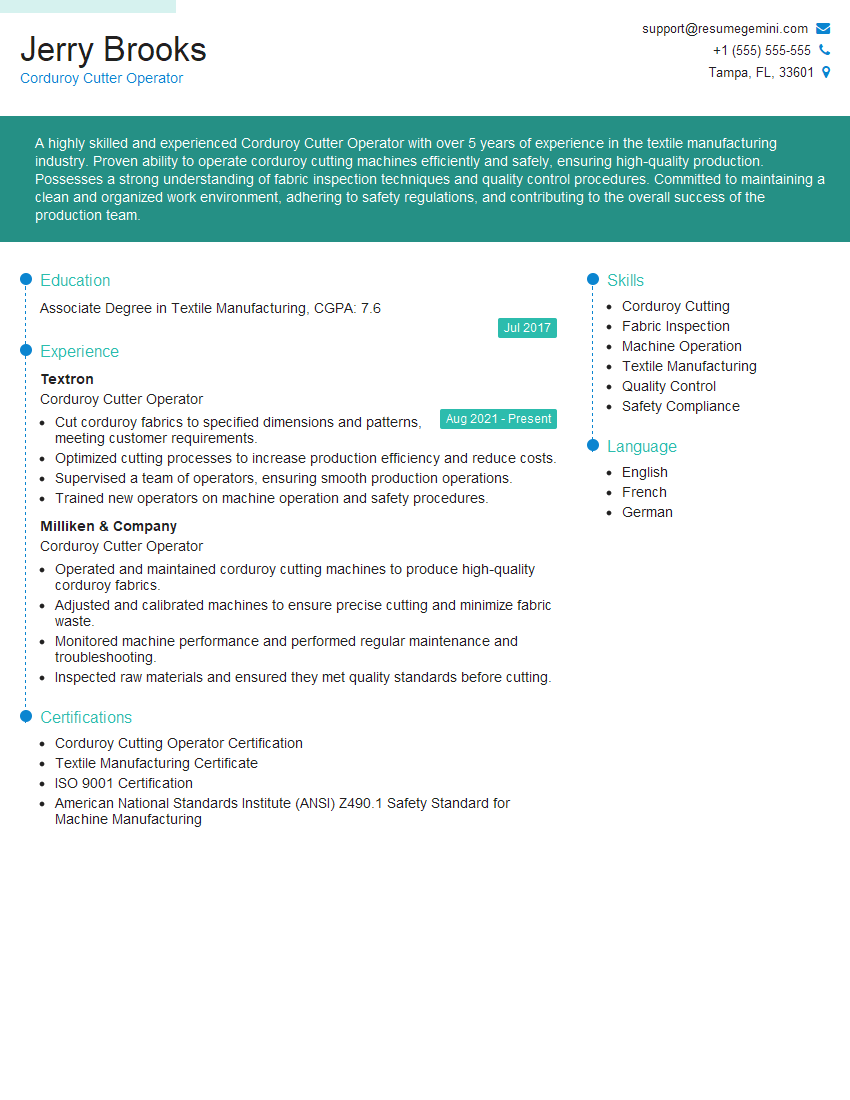

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Corduroy Cutter Operator

1. How do you determine the correct blade type and settings for various corduroy fabrics?

To determine the correct blade type and settings for various corduroy fabrics, I consider several factors:

- Fabric weight and thickness: Heavier fabrics require more aggressive blades and higher blade settings.

- Corduroy wale size: Finer wale sizes need sharper blades and lower blade settings.

- Fiber content: Synthetic fibers, like polyester, require different blade types and settings than natural fibers, like cotton.

- Desired corduroy texture: The blade type and settings can affect the height and definition of the corduroy wales.

2. What are the key steps involved in setting up and operating a corduroy cutting machine?

Machine Setup

- Blade selection and installation: Select the appropriate blade type and settings based on fabric characteristics.

- Fabric loading: Load the fabric onto the machine’s conveyor belt, ensuring proper alignment and tension.

- Speed and feed rate adjustment: Set the machine’s speed and feed rate to match the fabric type and desired cut quality.

Operation

- Monitoring fabric flow: Observe the fabric’s movement to ensure it is cutting correctly and not bunching up.

- Blade maintenance: Periodically check blade sharpness and adjust or replace blades as needed.

- Safety protocols: Follow established safety procedures, including wearing appropriate safety gear.

3. How do you handle defects or variations in the corduroy fabric during cutting?

When encountering defects or variations in the corduroy fabric, I take the following steps:

- Identify the defect: Determine the type of defect, such as broken wales, uneven height, or fabric flaws.

- Adjust settings or blades: If possible, adjust the blade settings or switch to a different blade type to minimize the impact of the defect.

- Isolate the affected area: Cut around the affected area and discard the defective section to prevent further damage.

- Inspect subsequent fabric: Carefully inspect subsequent fabric to identify any potential issues and take preventive measures.

4. What are the different types of corduroy cutting machines and their applications?

- Circular blade cutters: Used for cutting lighter fabrics and producing cleaner cuts.

- Reciprocating blade cutters: Suitable for heavier fabrics and can handle multiple layers of material.

- Laser cutters: Provide precise and intricate cuts, often used for delicate fabrics or complex designs.

- Ultrasonic cutters: Utilize high-frequency vibrations to cut fabrics without damaging the fibers.

5. How do you ensure consistency in cut quality and maintain the desired corduroy texture?

To ensure consistency and maintain the desired corduroy texture, I follow several practices:

- Regular blade maintenance: Maintain sharp blades to ensure clean and precise cuts.

- Consistent machine settings: Establish and adhere to optimal machine settings based on fabric type.

- Fabric pre-treatment: Properly condition the fabric before cutting to reduce wrinkles and improve cut quality.

- Quality control checks: Regularly inspect the cut fabric to identify and correct any deviations.

6. How do you handle and store corduroy fabric rolls to minimize damage or crease formation?

To minimize damage and crease formation in corduroy fabric rolls, I follow these guidelines:

- Proper storage: Store rolls in a dry and well-ventilated environment to prevent moisture damage and mildew.

- Roll orientation: Orient rolls vertically to distribute the weight evenly and prevent sagging.

- Protective covers: Use protective covers to shield rolls from dust, dirt, and sunlight.

- Avoid folding or bending: Handle rolls carefully to prevent creases or wrinkles.

7. What troubleshooting techniques do you use to resolve common issues encountered during corduroy cutting?

- Uneven cuts: Check blade sharpness and adjust settings accordingly.

- Fabric fraying: Use a sharper blade or adjust the blade angle.

- Missed cuts: Ensure proper blade alignment and adjust machine speed.

- Creases or wrinkles in fabric: Pre-condition the fabric and adjust machine tension.

- Machine downtime: Follow regular maintenance schedules and address mechanical issues promptly.

8. How do you measure and maintain the correct pile height of the corduroy fabric during cutting?

To measure and maintain the correct pile height during cutting, I use the following techniques:

- Blade angle adjustment: Adjust the blade angle to achieve the desired pile height.

- Gauge settings: Utilize gauges or rulers to measure the pile height and adjust settings accordingly.

- Cut samples: Take cut samples and measure the pile height to verify accuracy.

- Regular monitoring: Monitor the pile height throughout the cutting process to ensure consistency.

9. What strategies do you employ to minimize fabric waste and optimize cutting efficiency?

- Efficient layout: Plan fabric layout to minimize remnants and optimize fabric utilization.

- Batch cutting: Cut similar fabrics together to reduce setup time and waste.

- Remnant utilization: Use fabric remnants for smaller items or as testing material.

- Training and experience: Invest in training and develop expertise to reduce operator errors and waste.

10. How do you ensure the safety of yourself and others while operating a corduroy cutting machine?

- Protective gear: Wear appropriate safety gear, including gloves, safety glasses, and hearing protection.

- Proper training: Follow established safety protocols and receive thorough training on machine operation.

- Machine maintenance: Regularly inspect and maintain the machine to prevent malfunctions or accidents.

- Sharp blades: Maintain sharp blades to reduce the risk of kickback or injury.

- Clear work area: Keep the work area clean and free of clutter to minimize trip and fall hazards.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Corduroy Cutter Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Corduroy Cutter Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Corduroy Cutter Operators are responsible for operating specialized machinery to cut corduroy fabrics. They ensure the efficient production of high-quality corduroy by adhering to specified patterns and maintaining the proper functioning of the machines.

1. Fabric Preparation

Inspect the corduroy fabric rolls for any defects or irregularities.

- Measure and mark the fabric according to the cutting specifications.

- Load the fabric onto the cutting machine.

2. Machine Operation

Operate the corduroy cutting machine to cut the fabric into specified corduroy patterns.

- Monitor and adjust machine settings to ensure precise cutting and maintain production efficiency.

- Troubleshoot and resolve any malfunctions or issues with the cutting machine.

3. Quality Control

Inspect the cut corduroy fabric for accuracy, quality, and adherence to specifications.

- Identify and correct any defects or irregularities in the cut corduroy.

- Maintain detailed records of production output and quality control checks.

4. Machine Maintenance

Perform routine maintenance and cleaning of the corduroy cutting machine.

- Lubricate and adjust machine components to ensure optimal performance.

- Monitor machine wear and tear and report any issues to supervisors.

Interview Tips

To help you ace the interview for a Corduroy Cutter Operator position, here are some preparation tips and advice:

1. Research the Company and Position

Familiarize yourself with the company’s background, values, and the specific requirements of the Corduroy Cutter Operator role.

- Visit the company website and read about their products, services, and mission.

- Study the job description thoroughly to identify key responsibilities and qualifications.

2. Highlight Relevant Skills and Experience

Emphasize your skills in operating corduroy cutting machinery, fabric inspection, and quality control.

- Quantify your achievements and provide specific examples of your contributions in previous roles.

- Discuss your understanding of corduroy cutting techniques and the importance of maintaining high-quality standards.

3. Demonstrate Technical Knowledge

Showcase your technical knowledge of the corduroy cutting process and equipment.

- Explain the different types of corduroy cutting machines and their uses.

- Discuss the factors that affect the quality of the cut fabric, such as blade sharpness and fabric tension.

4. Prepare for Common Interview Questions

Practice answering common interview questions related to your skills, experience, and motivations.

- Prepare a concise and compelling response to “Tell me about yourself” that highlights your relevant qualifications.

- Brainstorm examples of challenges you have faced in previous roles and how you overcame them.

5. Dress Professionally and Be Punctual

First impressions matter. Dress appropriately for the interview and arrive on time to demonstrate your respect for the interviewer and the position.

- Choose business casual attire that is clean, pressed, and fits comfortably.

- Plan your route to the interview location in advance to avoid any delays.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Corduroy Cutter Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!